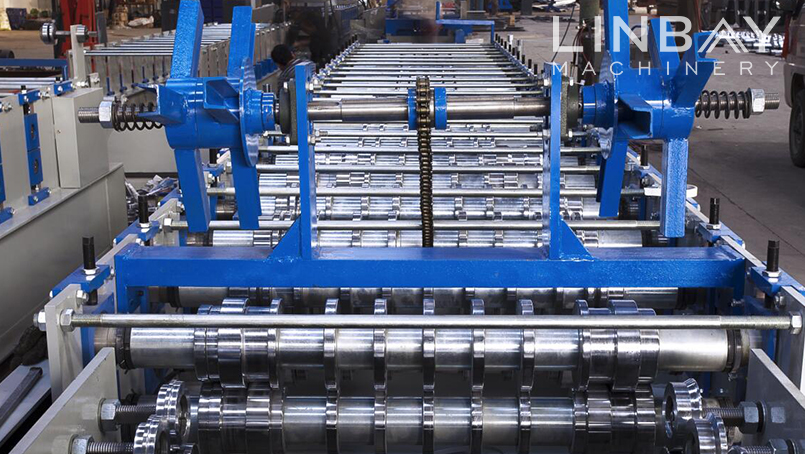

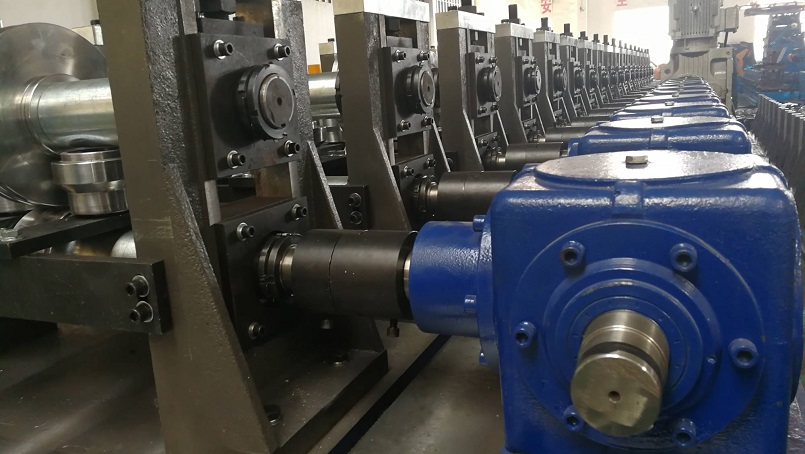

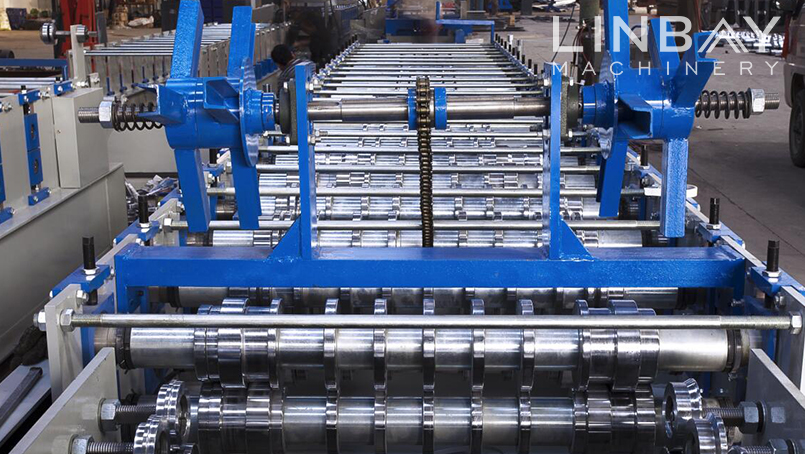

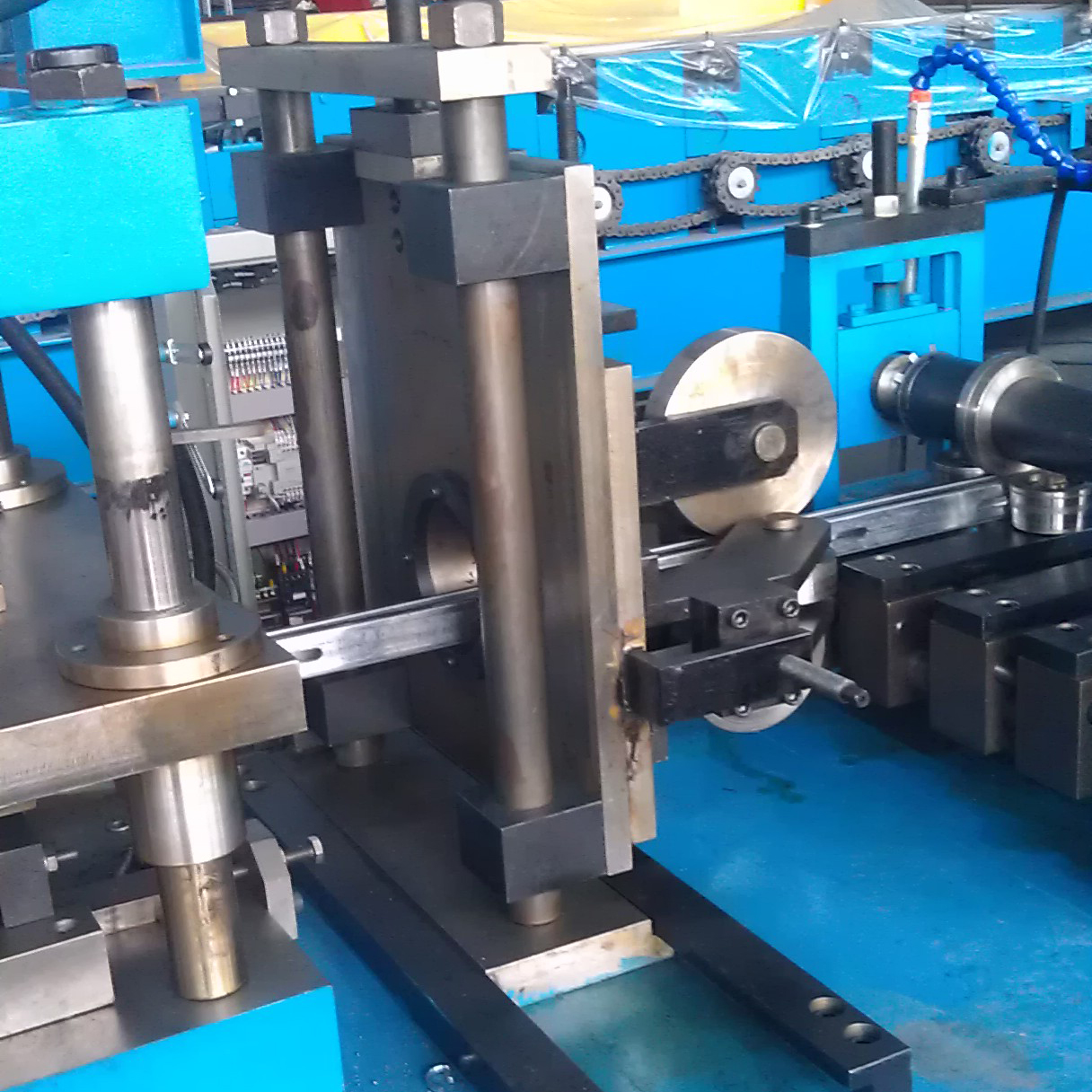

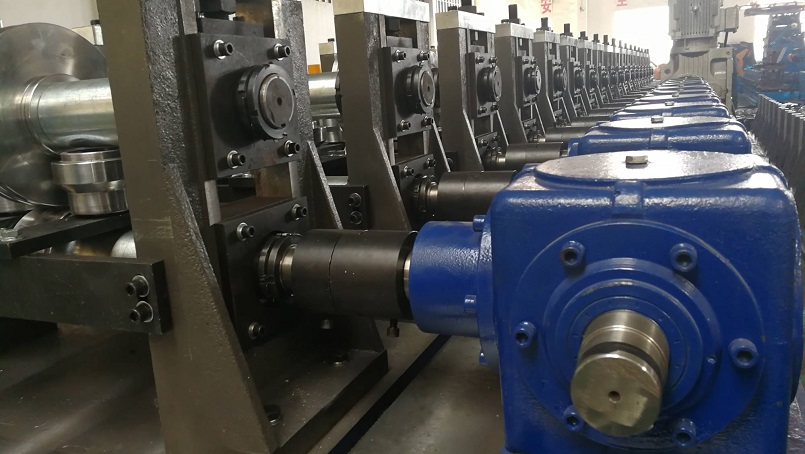

This Steel Silo Roll Forming Machine can produce 4-5mm corrugated sheets. We use forged iron stands and some customers ask gearbox driving system to mantain the machine work stablely.

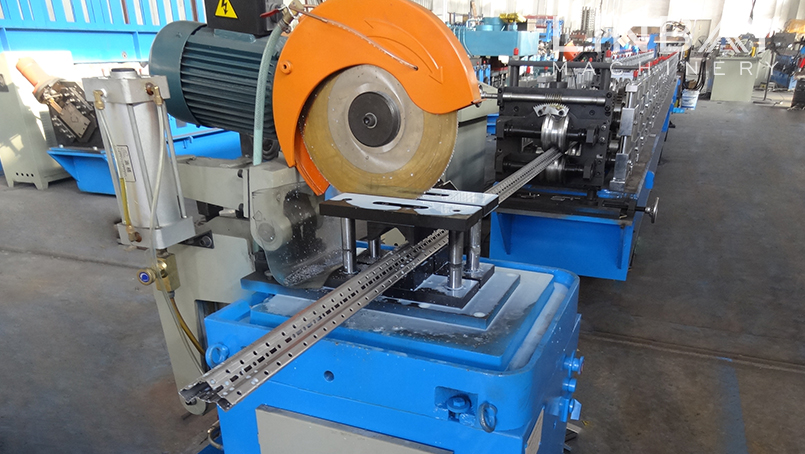

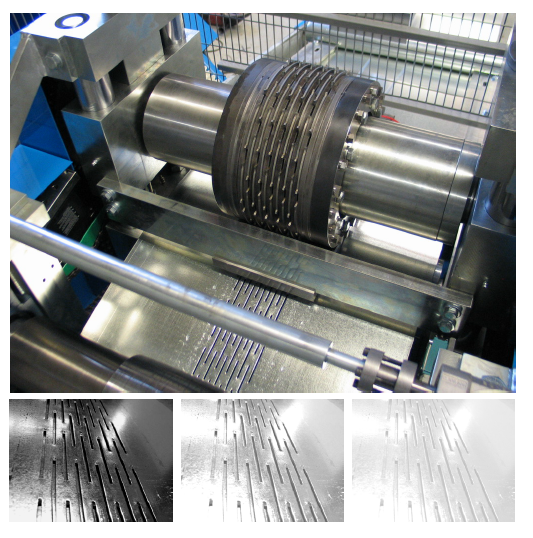

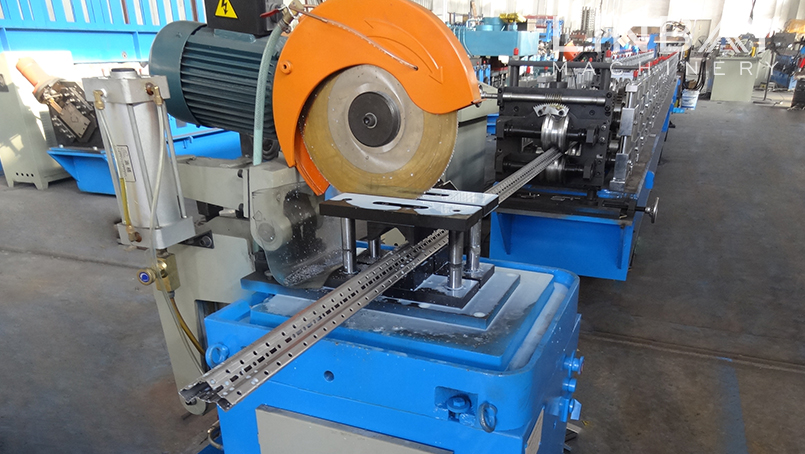

Max working speed is around 8m/min with punching holes, cutting and curving process.

This steel silo is widely used granary,warehouse, grain storage etc.

|

Steel silo roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):4-5 |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

5-8 |

Or according to your requirement |

|

3 |

Forming station |

18 |

According to your profile |

|

4 |

Decoiler |

Hydraulic decoiler |

Manual decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

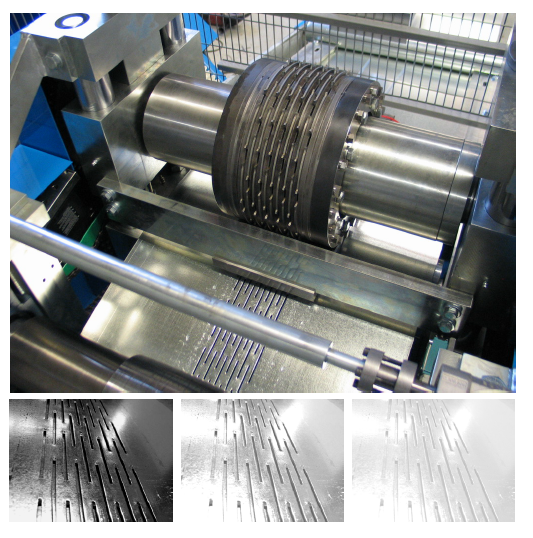

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Forged iron station |

Wall panel station |

|

11 |

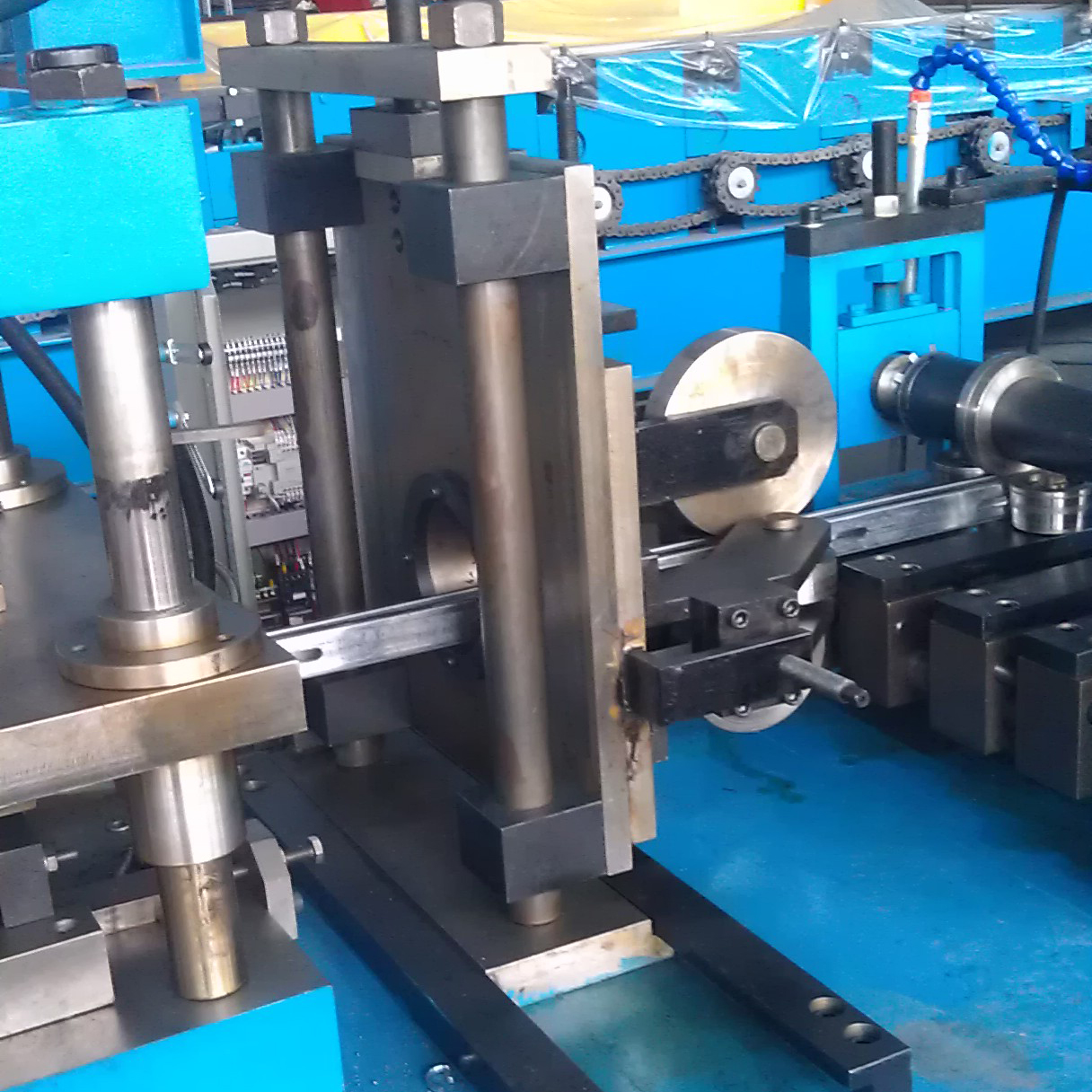

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

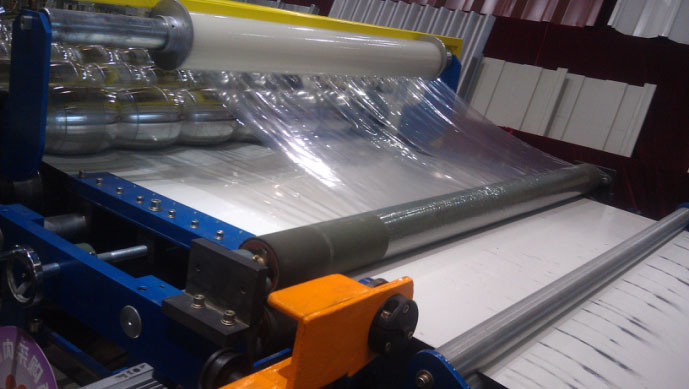

Manual decoiler--feeding--forming machine--hydraulic cutting--out table

-

Others

-

Scrap Collector

-

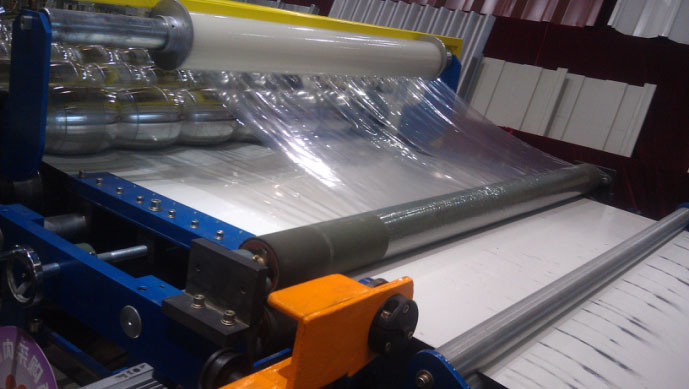

Pasting

-

Mould Change

-

Guiding Head

-

Sooling System

-

-

Out table

-

Non-Powered

-

Auto Stacker

-

-

Cutting

-

Fixed Saw Cutting

-

Flying Shear

-

Universe Cutting

-

-

Driving

-

Chain Drive

-

Gearbox Drive

-

Gearbox Drive With Coupling

-

-

Stands

-

Wall Panel Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel For C Purlin

-

-

Punching

-

Hydraulic Punching Station

-

Punching Press

-

Roller Punching

-

-

Feeding

-

Leveling

-

Servo Feeding

-

-

Decoiler

-

Manual Decoiler

-

Hydraulic Decoiler

-

Double Head Decoiler

-

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)