Pre-cut highway guardrail W beam roll forming machine

A standard W-beam section spans 4 meters in length and is pre-punched at both ends to facilitate installation. Tailoring to customer requirements for production speed and floor space, we offer customizable hole-punching solutions integrated seamlessly into the primary forming machine production line.

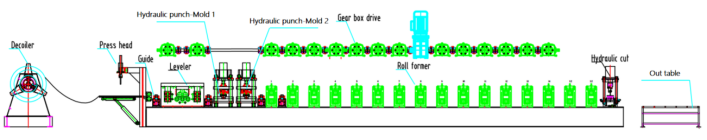

Flow chart: Hydraulic decoiler--Leveler--Servo feeder--Hydraulic punch--Pre cut--Platform--Guiding--Roll former--Out table

- Line speed: 0-12m/min, adjustable

- Suitable material: Hot rolled steel, cold rolled steel

- Material thickness: 2-4mm

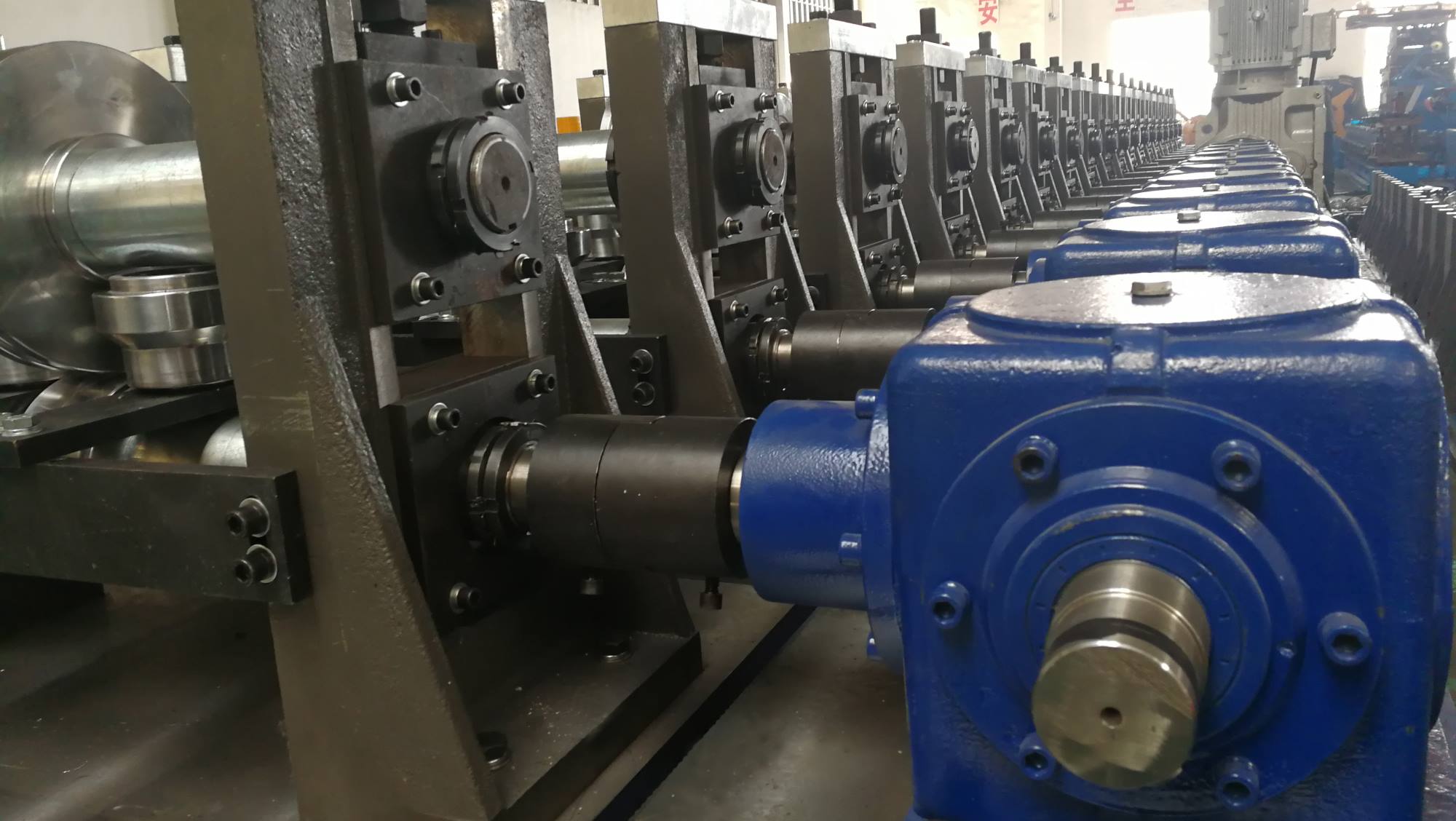

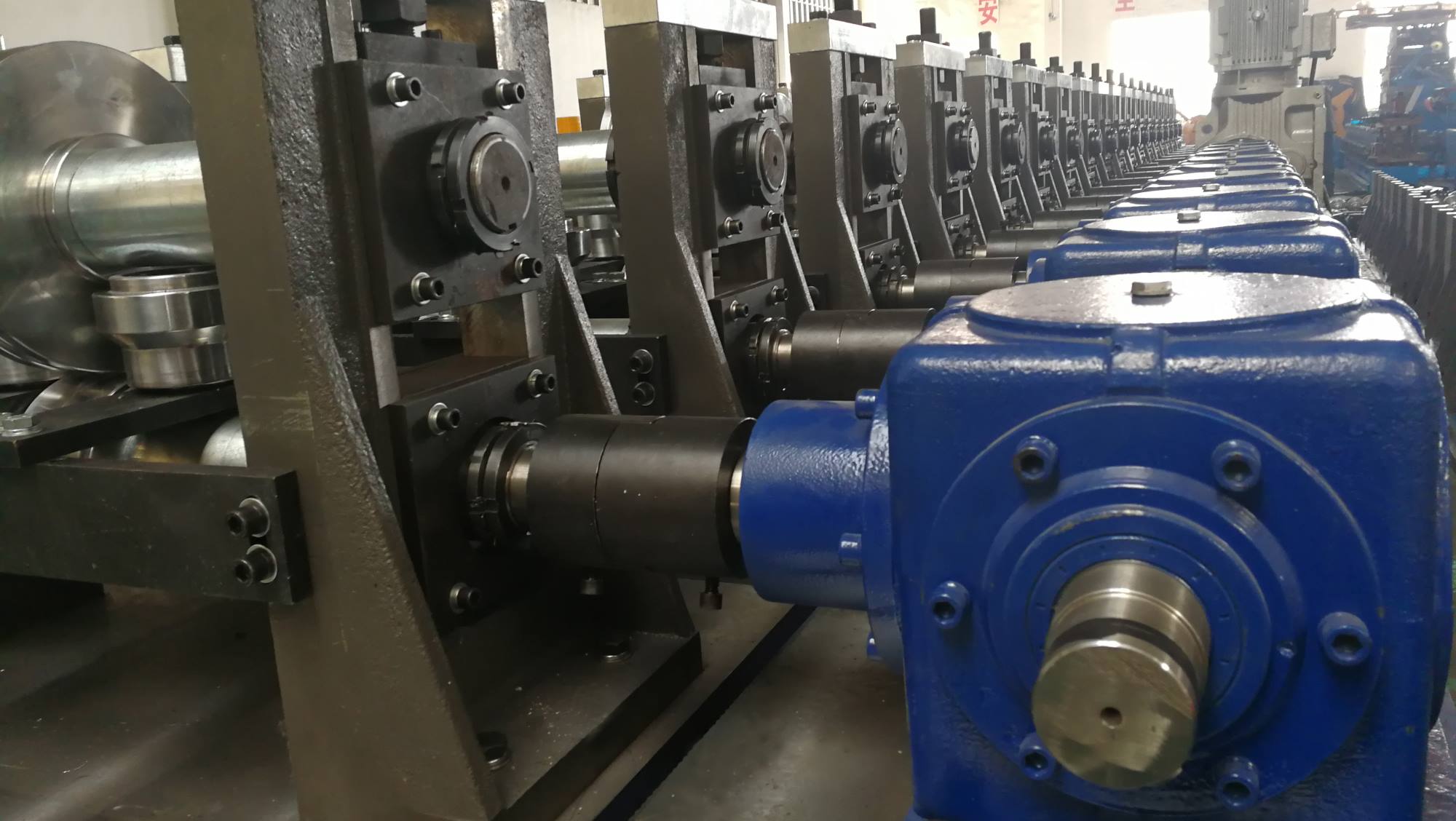

- Roll forming machine: Cast-iron structure and universal joint

- Driving system: Gearbox driving system with universal joint cardan shaft.

- Cutting system: Cut before roll forming, roll former doesn’t stop when cutting

- PLC cabinet: Siemens system

- Decoiler*1

- Leveler*1

- Servo feeder*1

- Hydraulic punch machine*1

- Hydraulic cutting machine*1

- Platform*1

- Roll forming machine*1

- Out table*2

- PLC control cabinet*2

- Hydraulic station*2

- Spare parts box(Free)*1

Container size: 2x40GP

Hydraulic decoiler

The hydraulic decoiler boasts two safety features: the press arm and the outward coil retainer. During coil replacement, the press arm firmly secures the coil, preventing the steel coil from springing open due to the internal tension. Meanwhile, the outward coil retainer ensures the coil remains its place during undecoiling.

The decoiler's core expansion device is adaptable, able to contract or expand to fit coil inner diameters ranging from 460-520mm.

Leveler

The leveler is important for flattening the coil and maintaining consistent thickness. Using a separate leveler ensures the best performance.

We also offer the combined decoiler and leveler (2 in 1 decoiler) to save space and costs if you are interested. It makes alignment, feeding, installation, and debugging easier.

Servo Feeder

Featuring a servo motor, the feeder almost has no start-stop delays, precisely controlling coil feed length for accurate punching. Internally, pneumatic feeding safeguards the coil surface against abrasion.

Hydraulic Punch & Pre-cut Hydraulic Cutting Machine

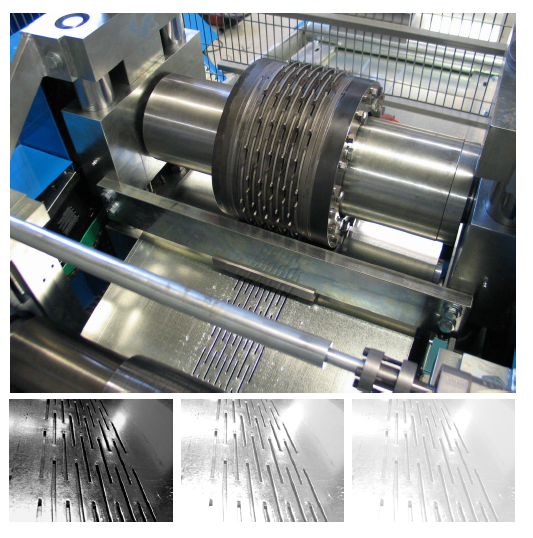

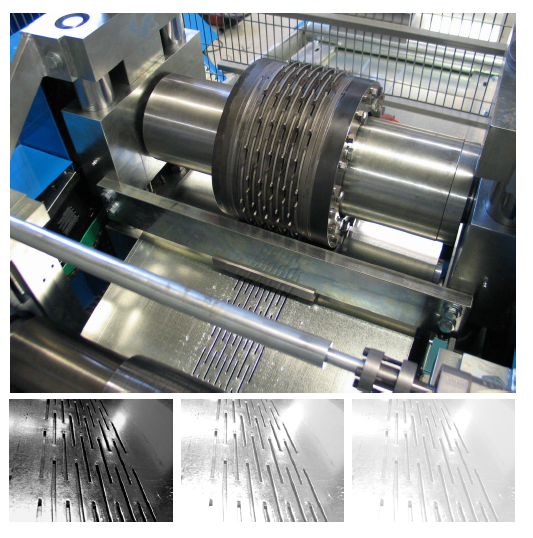

To enhance efficiency and cost-effectiveness, punching part is taken by two hydraulic station(two molds).

The first major station can punch 16 holes each time. The holes to be punched in the second station appear only once on each beam, making the smaller station a better solution.

Pre-cutting before roll forming ensures the uninterrupted operation of the roll forming machine, elevating production speed. Additionally, this solution minimizes the wastage of steel coil.

Guiding

Guiding rollers positioned before roll forming machine ensure steel coil and machine alignment, preventing coil distortion during forming.

Roll Forming machine

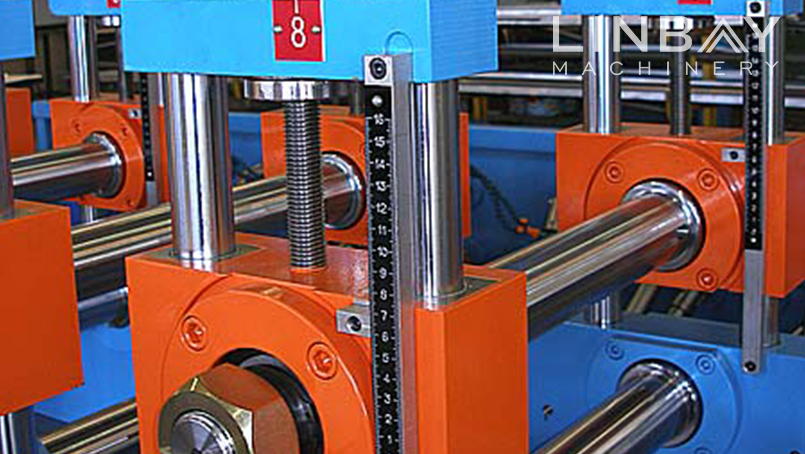

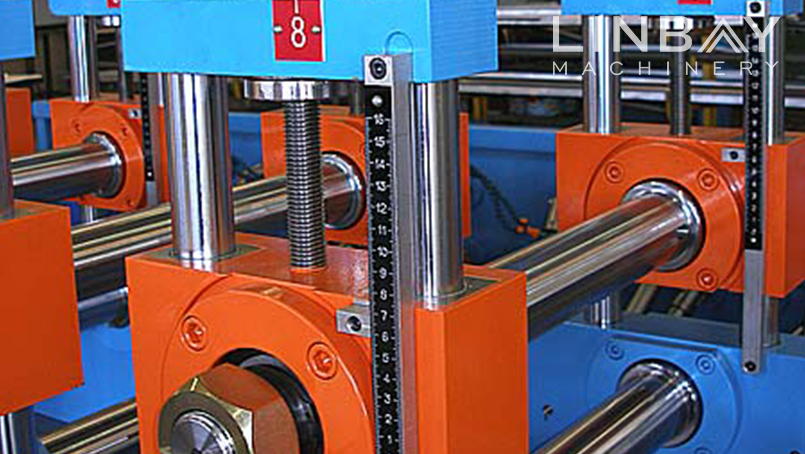

This roll forming machine utilizes a cast-iron structure, with universal shafts connecting the forming rollers and gearboxes. The steel coil undergoes deformation through a total of 12 forming stations until it conforms to the W beam shape specified in the customer's drawings.

The surface of the forming rollers is chromed to protect its surface and extend the lifespan of the rollers.

Optional: Auto stacker

At the end of the production line, utilizing an auto stacker can reduce manual labor costs by approximately two workers. Additionally, due to the weight of a 4m-long W beam, manual handling poses safety risks.

Auto stacker is a common and efficient option in roll forming production lines to enhance both efficiency and safety, priced according to length. Different profiles require different stacking methods. In this production line, a 4m-long auto stacker is equipped with three suction cups tailored for W-shaped profiles. The suction cups securely grasp the W beam and gently place it onto the conveyor for orderly stacking, facilitating transportation.

Production Speed: Typically, guardrail beams are 4m long. Pre-cutting achieves a speed of 12m/min, producing 180 beams per hour. Post-cutting runs at 6m/min, yielding 90 beams per hour.

Cutting Wastage: During cutting, the pre-cut solution generates zero waste or loss. In contrast, the post-cut solution generates waste of 18-20mm per cut, as per design specifications.

Line layout length: In the pre-cut solution, a transfer platform is required after cutting, which may result in a slightly longer production line layout compared to the post-cut solution.

Minimum Length: Generally, in the pre-cut solution, there is a requirement for the minimum length that can be cut, ensuring that there is steel coil within at least three sets of forming rollers. This ensures sufficient friction between the rollers and the steel coil to drive it forward. However, in the post-cut solution, there is no restriction on the minimum cutting length since the roll forming machine is filled with steel coil.

However, the W beam length is usually around 4m, exceeding the minimum length requirement. Therefore, there is no need to worry about the decision on pre-cut or post-cut solutions if this roll forming machine is for W beam.

Kind Advice: We recommend our clients choose a suitable production line based on their production quantity requirements. If you are the guardrail beam profile suppliers, the pre-cut solution is suitable for you. Although the cost of the pre-cut solution is slightly higher than the post-cut solution, its advantages in output can quickly offset the price disadvantage.

If you are procuring for a traffic construction project, the post-cut solution is more suitable for you. It occupies less space and comes at a slightly lower cost.

|

Two Waves/Three Waves Highway Guardrail Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

|

|

Thickness(mm):4-5 |

|

|

|

|

Yield strength: 250 - 550MPa |

|

|

|

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|

|

2 |

Nominal forming speed(m/min) |

15 |

Or according to your requirement |

|

3 |

Forming station |

12-15 |

According to your profile |

|

4 |

Decoiler |

Hydraulic decoiler |

|

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

Cr12 |

GCr15 or #45 Steel |

|

10 |

Station structure |

Forged Iron station |

Wall panel station

Or torri stand structure

|

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

1. Q: What kinds of experience do you have in producing highway guardrail roll forming machine?

A: We have experience of exporting our highway guardrail roll formers to Russia, Saudi Arabia, Turkey, Indonesia, India etc. We have produced AASHTO M180--American Guardrail standard (more useful and popular), RAL RG620--Germany Guardrail standard, BS EN-1317-- European Guardrail standard, AS/NZS 3845:1999--Australian Guardrail standard, EN 1461:2009 - Turkish Guardrail Standard.

2. Q: Can I produce W beam and Thrie beam guardrails on one machine?

A: One operator adds or takes off 5 stations of rollers according to our drawing. It wouldn't more than 30 minutes..

3. Q: How to change from producing W beam to thrie beam? And how long it takes?

A: According to the drawing given to replace forming rollers of last five forming station, process of changing just needs 30mins and only by one operator.

4. Q: What is delivery time of highway guardrail roll forming machine?

A: 80 days to 100 days depends on your drawing.

5. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally line speed is around 8m/min.

6. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

7. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Turkish Guardrail profile drawing:

Meet EN 1461:2009 Standard

-

Out table

-

Non-powered

-

Auto stacker

-

-

Cutting

-

flying shear

-

Saw cutting

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel

-

torri stands

-

forged iron

-

ruler

-

-

Punching

-

punching press

-

hydraulic punching station

-

roller punch

-

-

Feeding

-

Leveler

-

servo feeder

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-