Post-cut highway guardrail W beam roll forming machine

The guardrail W-beam is a commonly used safety barrier in transportation engineering projects such as highways, expressways, and bridges. Named for its resemblance to the letter "W" due to its dual peaks, this type of guardrail is typically fabricated from galvanized or hot-rolled steel ranging between 2-4mm in thickness.

Each section of W-beam is typically 4 meters long, with pre-punched holes at both ends for installation purposes. Depending on customer requirements for production speed and floor space, we can integrate suitable hole-punching solutions into the primary roll forming machine production line.Q&A

Flow chart: Hydraulic decoiler-Guiding-Leveler-Hydraulic punch-Roll former-Hydralic cut-Out table

- Line speed: 0-8m/min, adjustable

- Suitable material:Hot rolled steel, cold rolled steel

- Material thickness: 2-4mm

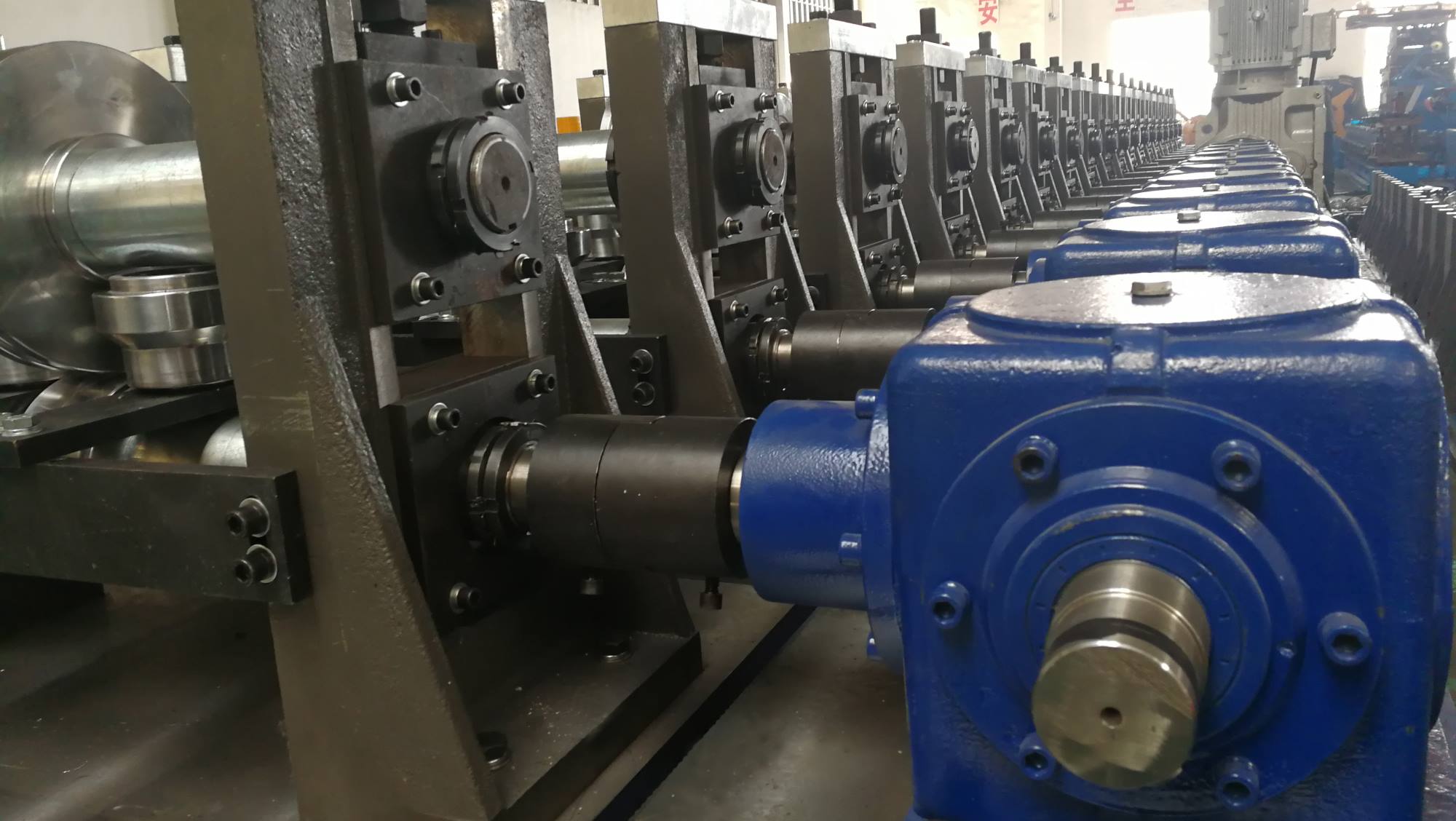

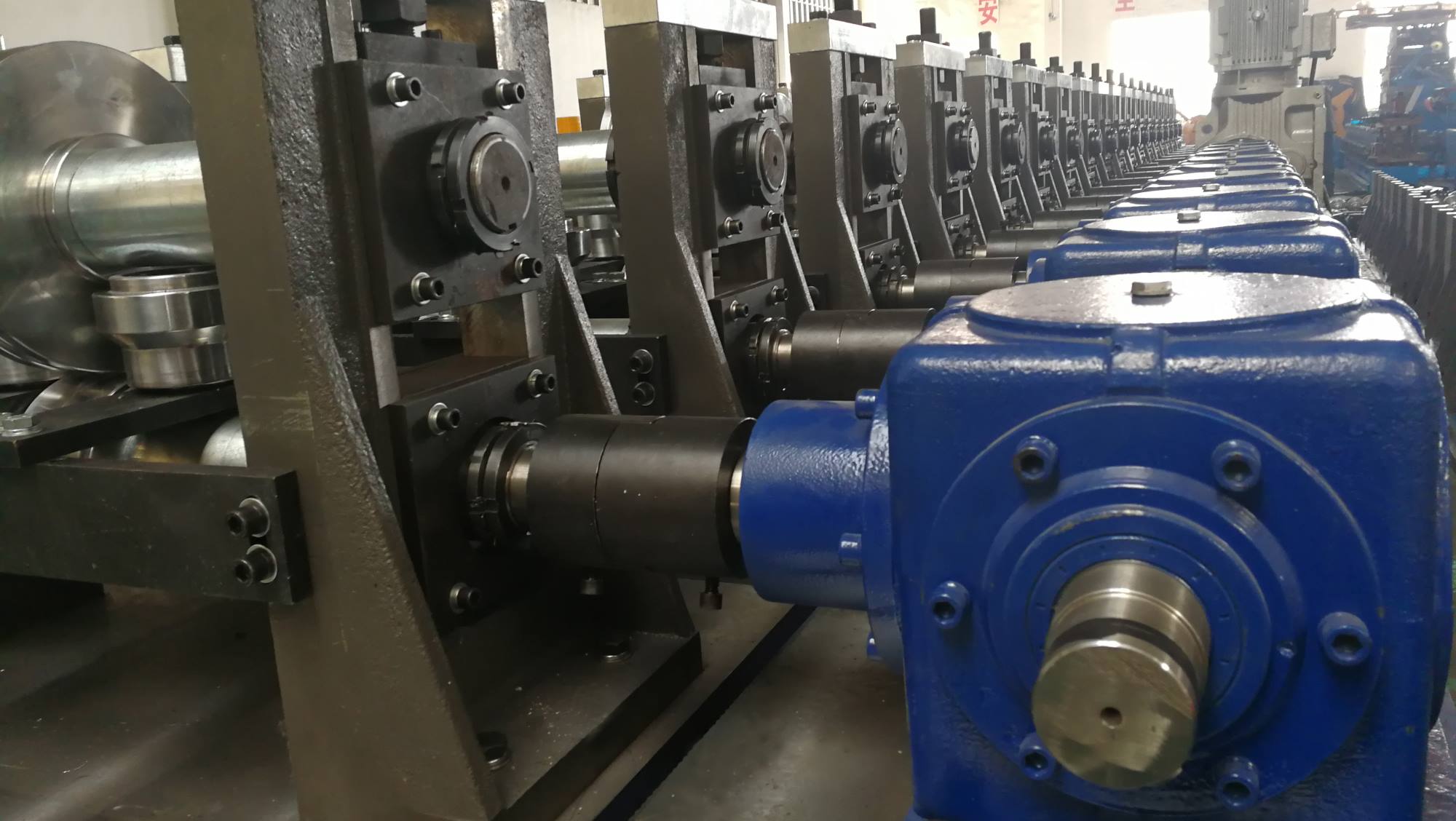

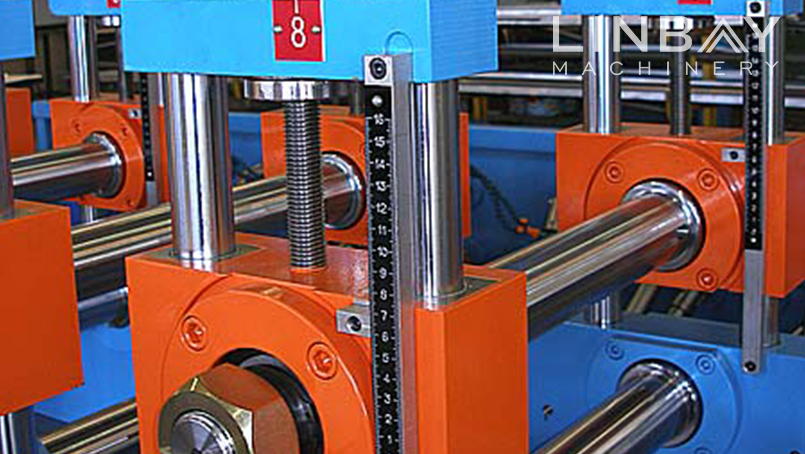

- Roll forming machine: Cast-iron structure and universal joint

- Driving system: Gearbox driving system with universal joint cardan shaft.

- Cutting system: Cut before roll forming, roll former doesn’t stop when cutting.

- Hydraulic decoiler*1

- Leveler(Equipped on the roll forming machine)*1

- Hydraulic punch machine*1

- Roll forming machine*1

- Hydraulic cutting machine*1

- Out table*2

- PLC control cabinet*1

- Hydraulic station*2

- Spare parts box(Free)*1

Container size: 2x40GP

Hydraulic Decoiler

The decoiler is equipped with two safety features: the press arm and the outward coil retainer. During coil replacement, the press arm secures the coil to prevent it from springing up and injuring workers. The outward coil retainer prevents the coil from slipping and falling during unwinding.

The decoiler is fitted with a standard four-piece core expansion device that can expand or contract to accommodate different coil inner diameters ranging from 460mm to 520mm.

Leveler & Press Head

A platform in front of the leveler, controlled by a hydraulic bar for vertical adjustment, assists in guiding the coil into the production line.

For profiles thicker than 1.5mm with punching requirements, using a leveler to flatten the coil and release internal stress for uniform thickness is essential for better punching and forming. In this case, the leveler is integrated with the main roll forming machine, using the same base.

For higher production speed requirements, we offer a standalone leveler, which slightly optimizes leveling speed but increases the overall length of the production line by approximately 3m.

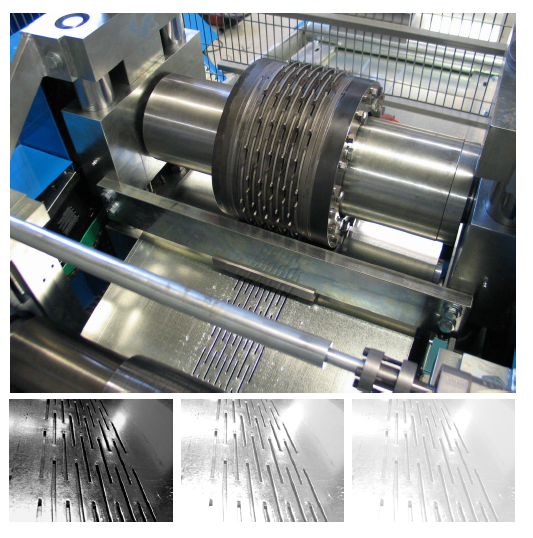

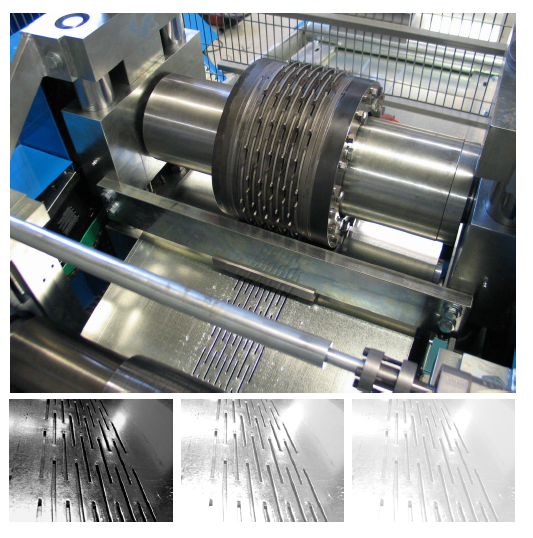

Hydraulic punch

For efficiency and cost considerations, punching can be divided between two dies (two stations), with the larger station capable of punching 16 holes at once. The second station can punch holes that appear only once on each beam.

Roll forming machine

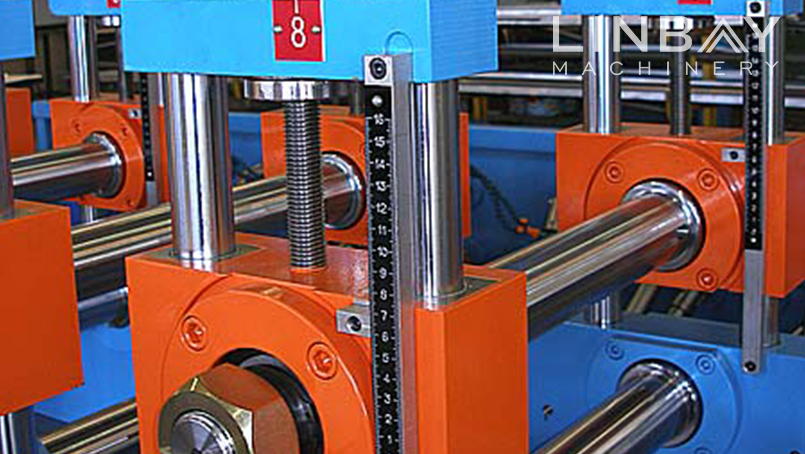

This roll former features a cast-iron structure, with universal shafts connecting the forming rollers and gearbox, ensuring robustness to efficiently meet the requirements for forming 2-4mm thick guardrail panels. The steel coil passes through a total of 12 forming stations to ultimately match the shape specified in the drawings.

Hydraulic cutting machine

As cutting occurs after forming, the cutting die must conform to the shape of the W-beam to reduce burrs and deformation of the cut edges. Configured for the stop-and-cut operation of the cutting machine, the forming machine briefly pauses during cutting.

Production Speed: Typically, guardrail beams are 4m long. Pre-cutting achieves a speed of 12m/min, producing 180 beams per hour. Post-cutting runs at 6m/min, yielding 90 beams per hour.

Cutting Wastage: During cutting, the pre-cut solution generates zero waste or loss. In contrast, the post-cut solution generates waste of 18-20mm per cut, as per design specifications.

Line layout length: In the pre-cut solution, a transfer platform is required after cutting, which may result in a slightly longer production line layout compared to the post-cut solution.

Impact on roll life: Better roller life in post-cut solution when running heavy gauge and high-strength steel because the leading edge in pre-cut solution hits the forming rollers with every part.

Minimum Length: Generally, in the pre-cut solution, there is a requirement for the minimum length that can be cut, ensuring that there is steel coil within at least three sets of forming rollers. This ensures sufficient friction between the rollers and the steel coil to drive it forward. However, in the post-cut solution, there is no restriction on the minimum cutting length since the roll forming machine is filled with steel coil.

However, the W beam length is usually around 4m, exceeding the minimum length requirement. Therefore, there is no need to worry about the decision on pre-cut or post-cut solutions if this roll forming machine is for W beam.

Kind Advice: We recommend our clients choose a suitable production line based on their production quantity requirements.

If you are the guardrail beam profile suppliers, the pre-cut solution is suitable for you. Although the cost of the pre-cut solution is slightly higher than the post-cut solution, its advantages in output can quickly offset the price disadvantage.

If you are procuring for a traffic construction project, the post-cut solution is more suitable for you. It occupies less space and comes at a slightly lower cost.

|

Two Waves/Three Waves Highway Guardrail Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

|

|

Thickness(mm):4-5 |

|

|

|

|

Yield strength: 250 - 550MPa |

|

|

|

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|

|

2 |

Nominal forming speed(m/min) |

15 |

Or according to your requirement |

|

3 |

Forming station |

12-15 |

According to your profile |

|

4 |

Decoiler |

Hydraulic decoiler |

|

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

Cr12 |

GCr15 or #45 Steel |

|

10 |

Station structure |

Forged Iron station |

Wall panel station

Or torri stand structure

|

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

1. Q: What kinds of experience do you have in producing highway guardrail roll forming machine?

A: We have experience of exporting our highway guardrail roll formers to Russia, Saudi Arabia, Turkey, Indonesia, India etc. We have produced AASHTO M180--American Guardrail standard (more useful and popular), RAL RG620--Germany Guardrail standard, BS EN-1317-- European Guardrail standard, AS/NZS 3845:1999--Australian Guardrail standard, EN 1461:2009 - Turkish Guardrail Standard.

2. Q: Can I produce W beam and Thrie beam guardrails on one machine?

A: One operator adds or takes off 5 stations of rollers according to our drawing. It wouldn't more than 30 minutes..

3. Q: How to change from producing W beam to thrie beam? And how long it takes?

A: According to the drawing given to replace forming rollers of last five forming station, process of changing just needs 30mins and only by one operator.

4. Q: What is delivery time of highway guardrail roll forming machine?

A: 80 days to 100 days depends on your drawing.

5. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally line speed is around 8m/min.

6. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

7. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Turkish Guardrail profile drawing:

Meet EN 1461:2009 Standard

-

Out table

-

Non-powered

-

Auto stacker

-

-

Cutting

-

flying shear

-

Saw cutting

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel

-

torri stands

-

forged iron

-

ruler

-

-

Punching

-

punching press

-

hydraulic punching station

-

roller punch

-

-

Feeding

-

Leveler

-

servo feeder

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-