The KBK crane rail of the KBK light crane system is an ideal product for linear overhead material handling and is a typical product in roll forming machines. The suspension monorail is widely used in all types of transport systems due to its high flexibility, versatility and relatively wide range of options.

The rails are easy to operate, high load capacity, flexible bends, fully or semi-automatic design, also with double track options, to meet the structural requirements of any workshop, the Demag Cranes system in Germany is a very well known company.

The material usually is steel and aluminum,surface ral coated, 3mm thickness, there are double rail as well according to the actual using situation.

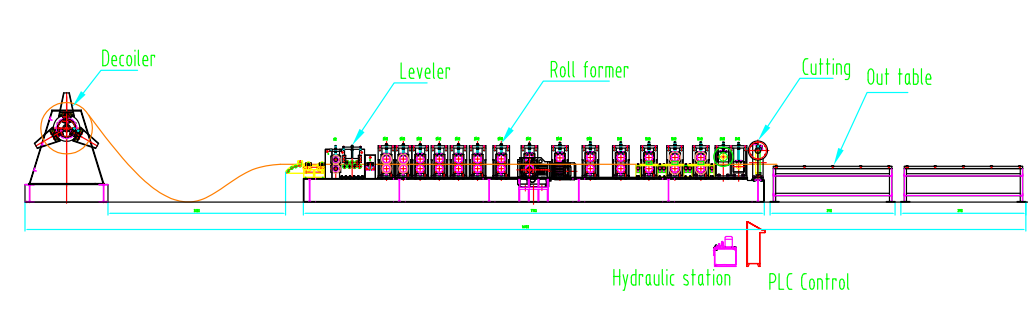

As you can see, in the picture, the main process is decoiler, leveler,roll former, cut, out tables. Here we adopt 5 tons hydraulic decoiler, integrated leveler, iron cast gear box drive, hydraulic saw cut. The hydraulic decoiler can save more manpower cost, keep the production work smoothly, steadily. Because of the material thickness, the leveler will be needed too. To eliminate the crossbow and stress on the coils, better for later formation.

The roll former’s structure must can bear high load, the iron cast and gear box drive will be the best choice. It can work at least 10 years and very favourable for later maintenance.The structure have the biggest intensity. The last saw cut is for better formation, it’s a good choice for cutting closed tubes.

The special feature of our machine is that previously others were doing half of a complete shape, this line is doing a complete profile, much increasing production efficiency and speeding up production output.

This production line working speed is around 0-5m/min according to cutting length, the forming speed is around 0-10m/min adjustable.

Hydraulic decoiler-Guiding-Leveler-Roll former-Hydraulic saw cut-Out tables

|

KBK Crane rail roll forming machine |

|||

|

NO. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):3mm |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensile stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

0-5m/min |

Or according to your requirement |

|

3 |

Forming station |

22 |

According to your profile |

|

4 |

Decoiler |

Hydraulic decoiler |

Manual decoiler or double head decoiler |

|

5 |

Main machine motor |

18.5kw Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Delta brand |

Siemens/Panasonic |

|

7 |

Inverter brand |

Delta brand |

Yaskawa |

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

GCr15 |

Steel #45 |

|

10 |

Station structure |

Forged Iron station |

Wall panel structure |

|

11 |

Punching system |

Hydraulic punching station |

Punching press |

|

12 |

Cutting system |

Post saw cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

1. Q: What kinds of experience do you have in producing bracing roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, Step beam roll forming machine and Shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2. Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. For upright rack beam, our customer usually make 3-4 sizes in one machine. We would check your profile drawings to meet your needs. In this way, we will greatly reduce your cost and time.

3.Q: What is delivery time of your bracing roll forming machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory-self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)