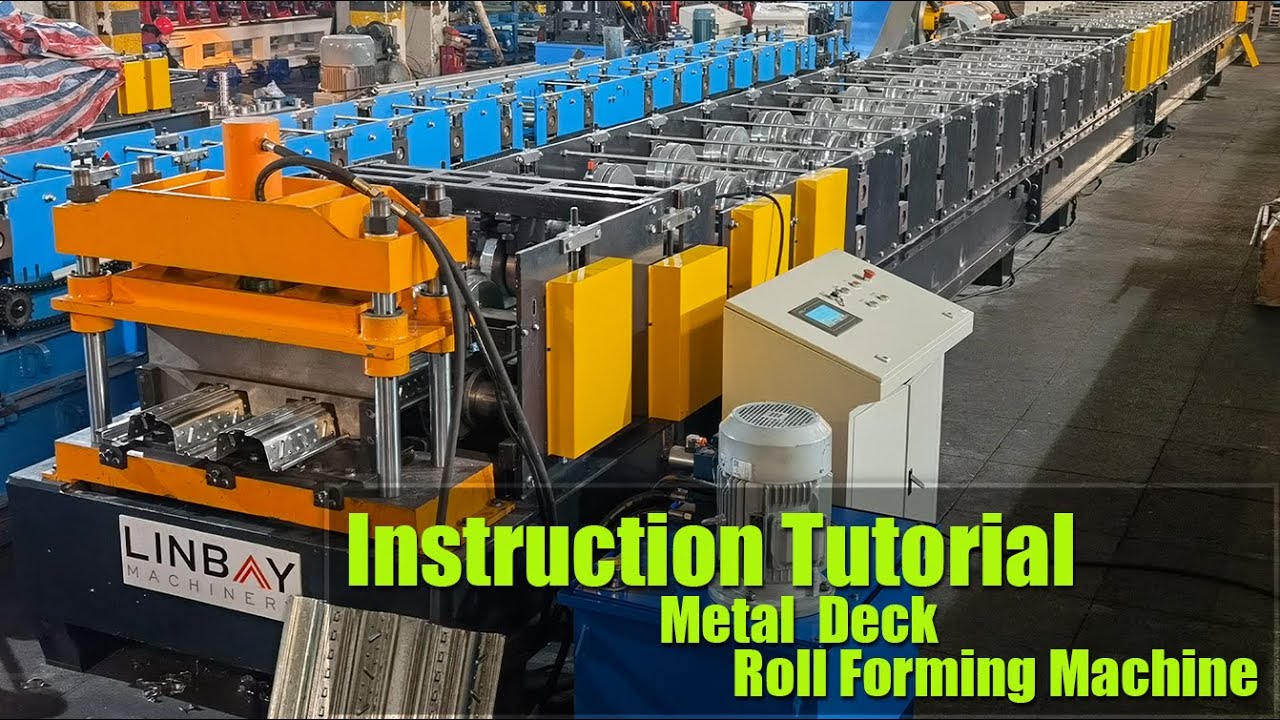

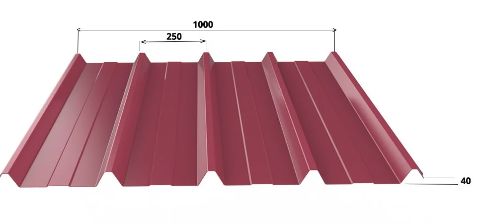

40/250 Trapezoidal roof panel roll forming machine

40/250 Trapezoidal roof panel roll forming machine is a kind of Roof panel Roll Forming Machine. Its normal thickness is 0.4-0.8mm. The raw material could be galvanized. Our machine has an extensive use in buildings such as industrial buildings, sheds, fattening farms。

In Construction Industries, we are able to manufacture more machines like WA200 roof panel roll forming machine, TR-72 roof panel roll forming machine, TO-100 roof panel roll forming machine etc.

Linbay makes different solutions according to the customer’s drawings, tolerances and budgets, providing professional one-on-one service to suit your various needs. Whichever production line you choose, the quality of Linbay Machinery will ensure that you get the perfect functional profile.

LINBAY will hereby explain how we install our machines.

First of all, we adjust the machine in the factory, we first ask the size you want to produce, we put the machine in the size that we want to produce and adjust all the correct parameters before shipping, so that you don’t have to change anything when you get this machine.

Then, when we disassemble the machines for debugging, we shoot videos so that you know how to connect them. Each machine has its own video. In the video, we will show how to connect cables and tubes, place oil, put physical structures together, etc...

Here is the example of this video: https://youtu.be/5unUrN93dsI

Hydraulic decoiler--guiding--roll former--electric cut--out table

Our 40/250Trapezoidal roof panel roll forming machine is first equipped with a hydraulic uncoiler. The hydraulic running motor power is 5.5kw and the hydraulic motor power is 3kw. Its feeding width is 1250mm. The material of the coil could be Prepainted Galvanized Steel and the normal thickness is 0.4-0.8mm. The yield strength of the coil is 300Mpa. This entire production line Weighs 12 tons. Going through the guiding part, is the main body of the roll forming machine. We choose a chain-driven wall panel structure which is more stable. There are 25 stands in the forming station and we provide a 11kw motor. The speed of the forming machine is 15m/min. In the shearing part the machine uses an electric cut. This cutting method is high efficiency which will increase the cutting speed. Finally, there is an out table.

We have extensive export experience, for example, USA, South Africa, Cameroon, Ghana etc.

Here are some pictures of our machine:

| 40/250Trapezoidal Roof Panel Roll Forming Machine | ||

| Machinable Material : | Prepainted Galvanized Steel | Thickness(MM):0.4-0.8 |

| Yield strength : | 300 Mpa | |

| Nominal forming speed(M/MIN): | 0-15 | * Or according to your requirement (Optional) |

| Forming station : | 25 stands | * According to your steel material |

| Decoiler : | Hydraulic decoiler | |

| Main machine motor brand : | Simens Brand | |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station (Optional) |

| Rollers’ material : | GCr15 | * Cr 12 (Optional) |

| Cutting system : | Electric cut | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)