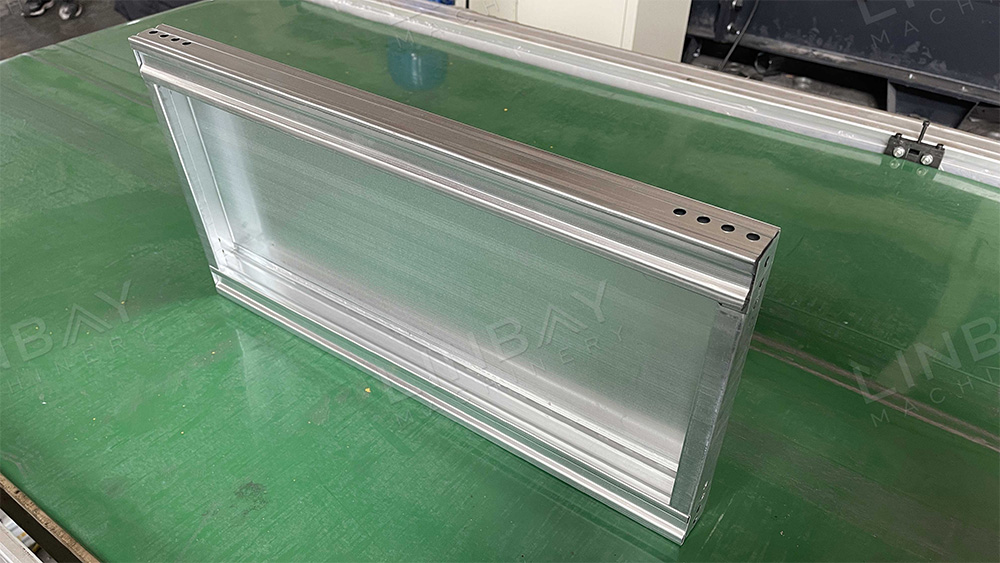

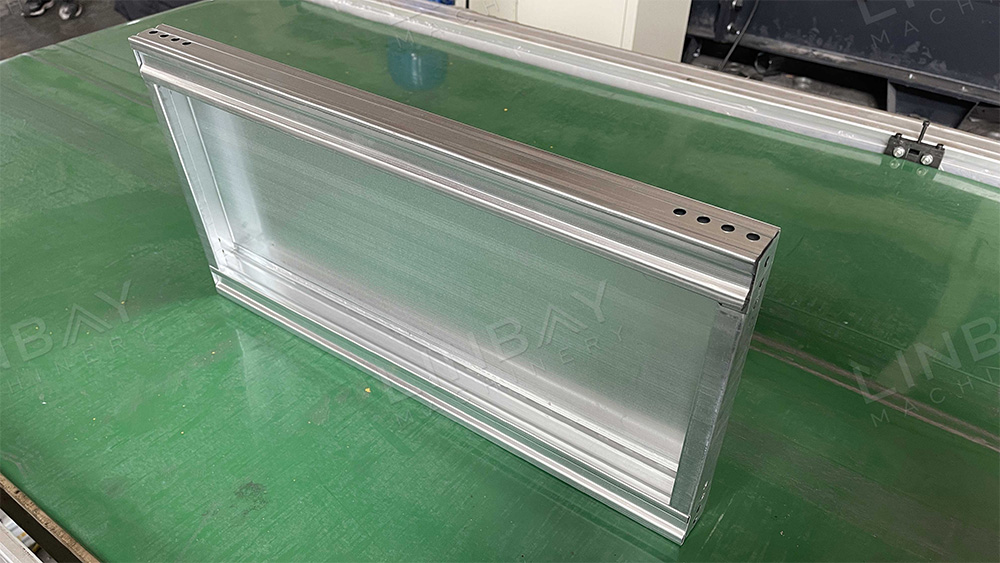

The shelf panel is a important component in the racking system designed to support goods. Typically manufactured from galvanized steel with a thickness of 1-2mm. This shelf panel comes in various width and length dimensions, with a fixed height. It features a single bend on the wide side.

Real case-Main Technical Parameters

Flow chart

Hydraulic decoiler with leveler--Servo feeder--Hydraulic punch--Guiding--Roll forming machine--Cutting and bending machine--Out table

Main Techinical Parameters

- Line speed: 4-5 m/min, adjustable

- Profiles: Different width, different length and same height.

- Material thickness: 0.6-1.2mm (in this case)

- Suitable material:Hot rolled steel, cold rolled steel

- Roll forming machine: Cantilevereddouble-wall panel structure and chain driving system.

- Cutting and bending system: Cut and bend at the same time, roll former stops when cutting and bending.

- Changing size: Automatically.

- PLC cabinet: Siemens system.

Real case-Description

Hydraulic Decoiler with Leveler

This machine integrates a decoiler and leveler, saving factory floor space and land costs. The core expansion can contract and expand to accommodate different steel coils with internal diameters ranging from 460mm to 520mm. During uncoiling, the outward coil retainers prevents the steel coil from slipping off the decoiler. This can protect the safety of workers.

The leveler flattens the steel coil, releasing internal stress, facilitating better punching and roll forming.

Servo Feeder & Hydraulic Punch

The hydraulic punch operates independently, not sharing the same base with the roll forming machine. This allows continuous operation of the roll forming machine during punching, optimizing the overall production line's efficiency. The servo motor almost has no start-stop time delays, ensuring precise control of the steel coil's forward length for accurate punching.

In addition to the functional holes for screw installation, the notches are also created during the punching stage. As the flat steel coil will be formed into a three-dimensional panel, these notches are precisely calculated to prevent overlapping or significant gaps at the 4 corners of the shelf panel.

Encoder & PLC

The encoder converts the sensed steel coil length into an electrical signal transmitted to the PLC control cabinet. In the control cabinet, production speed, quantity per production, cutting length, etc., can be controlled. With accurate measurement and feedback from the encoder, the hydraulic cut can control cutting errors within ±1mm.

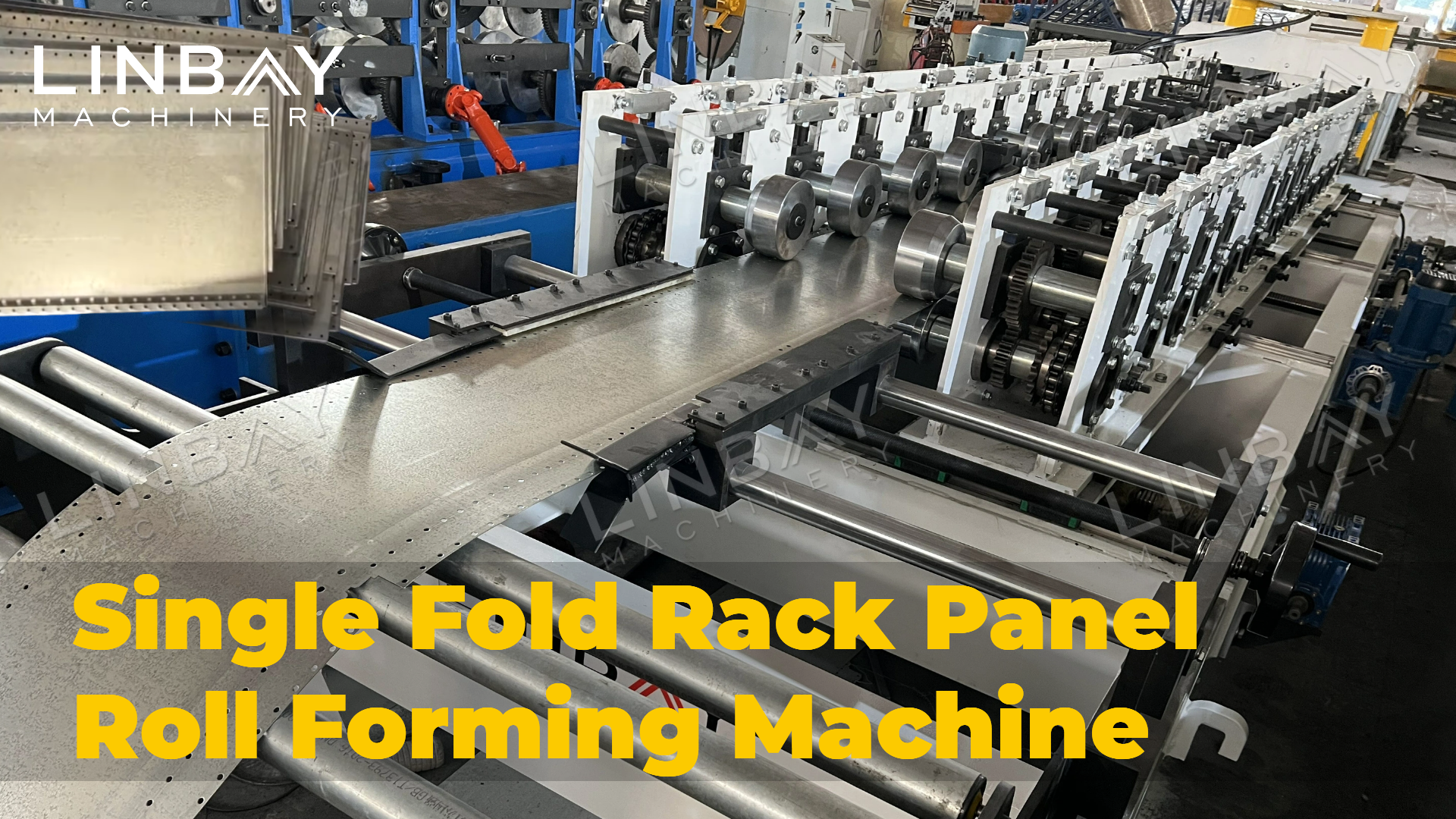

Roll Forming Machine

Before entering the forming machine, the steel coil passes through guiding bars to keep the coil on the same center line. Considering the shape of the shelf panel, only the sides of the steel coil need to be formed, so we use the double wall panel cantilever structure to minimize material usage, saving roller material costs. Chain-drive rollers apply force to the steel coil for advancement and forming.

The forming machine can produce shelf panels of various widths. Inputting desired dimensions into the PLC control panel, the forming station automatically moves on rails upon receiving signals, and the forming points on the steel coil change with the forming station and roller movement. That’s how this roll forming machine can produce shelf panels of different sizes.

An encoder is equipped to sense the forming station's movement for accurate size changes. Additionally, two position sensors, the outermost position sensor and innermost position sensor, prevent excessive movement on the rails, avoiding slipping or roller collisions.

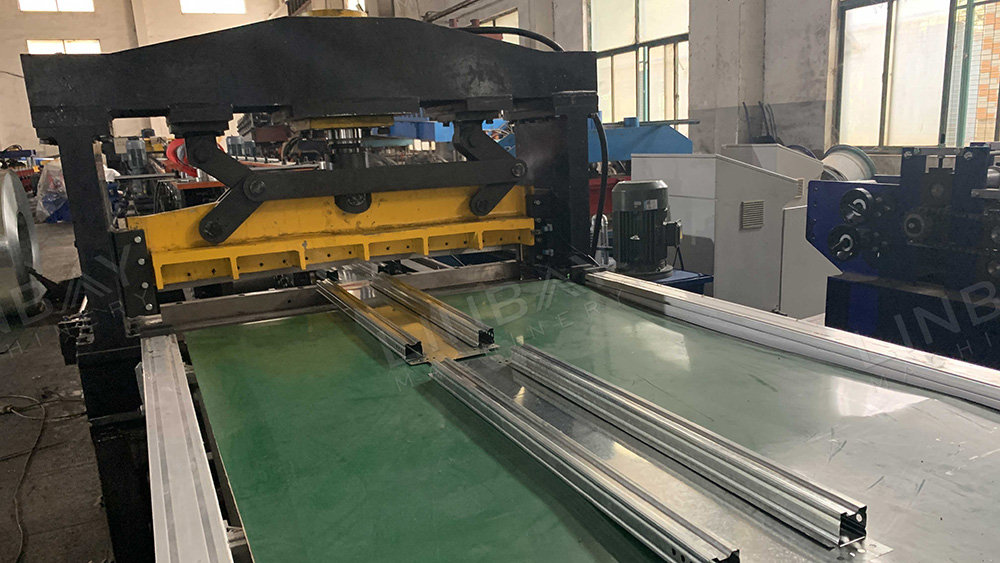

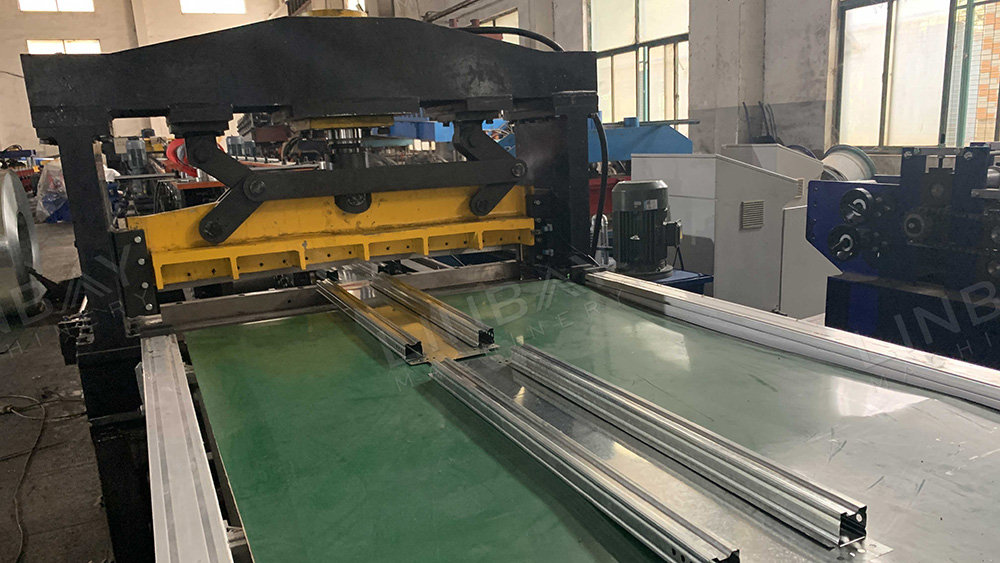

Cutting and Bending Machine

The shelf panel in this case requiring a single bend on the wide side, we designed the cutting machine's mold to simultaneously cut and bend.

The blade descends for cutting, then the bending mold moves upward, efficiently completing the first panel's tail and the second panel's head bending.

Other Type

If you are interested in shelf panel with two bends on the wide side, click the image to learn more about the detailed production process and video.

Key differences:

- Double-bend type provides superior durability, while single-bend type also meets storage needs adequately.

- Double-bend type edges are not sharp, making them safer to use.

|

Shelf Panel Roll Forming Machine |

|||

|

NO. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Cold-rolled steel, Galvanized steel, PPGI, stainless steel |

|

|

Thickness(mm):0.6-1mm |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensile stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

0-10m/min |

Or according to your requirement |

|

3 |

Forming station |

14 |

According to your profile |

|

4 |

Bending station |

2 |

According to your profile |

|

5 |

Decoiler |

5 ton hydraulic decoiler with leveling |

/ |

|

6 |

Main machine motor |

11kw Sino-German Brand |

Siemens |

|

7 |

PLC brand |

Siemens brand |

Panasonic/Delta |

|

8 |

Inverter brand |

Yaskawa brand |

Delta |

|

9 |

Driving system |

Chain drive |

Gear box drive |

|

10 |

Rollers’ materail |

Steel #45 |

Cr12Mov/GCr15 |

|

11 |

Station structure |

Cantilever wall panel |

Iron cast structure |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

|

15 |

Contactor |

Schneider brand |

Or according to your requirement |

-

Hydraulic punch

-

Transport platform for triple folded shelf panel

-

Triple folded shelf panel

-

Decoiler and leveler

1. Q: What kinds of experience do you have in producing bracing roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, Step beam roll forming machine and Shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2. Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. For upright rack beam, our customer usually make 3-4 sizes in one machine. We would check your profile drawings to meet your needs. In this way, we will greatly reduce your cost and time.

3.Q: What is delivery time of your bracing roll forming machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory-self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.