Flying Saw Cutting Step Beam Roll Forming Machine

The step beam is a crucial component in heavy-duty pallet racking system, and its quality directly impacts the strength and loading capacity of the racking system.

Step beam manufacturers typically use the roll forming machine with 1.5-2mm hot-rolled steel or cold-rolled steel to produce step beam. To enhance the step beam's lifespan and prevent deformation due to steel coil tension, welding is applied at the steel coil joints. Two common processes in the industry are MIG welder (as in this case) or laser full welder.

Both MIG welder and laser full welder can serve to reinforce structural integrity. However, due to the comprehensive coverage of joints in full welding, its effectiveness is inevitably superior to MIG welder. Customers can choose based on their budget and the rack loading requirements.

- Flow chart

Manual decoiler--Guiding--Leveler--Roll forming machine--Flying welder--Flying saw cutting--Out table

- Main Techinical Parameters

Line speed: 4-5 m/min, adjustable

Profiles: Multiple sizes-same width of 66mm, and different height of 76.2-165.1mm

Material thickness: 1.9mm (in this case)

Suitable material:Hot rolled steel, cold rolled steel, galvanized steel

Roll forming machine: Cast-iron structure and chain driving system.

No. Of forming station: 26

Welding system: 2*welding torches, roll former doesn’t stop when welding.

Cutting system: Saw cutting, roll former doesn’t stop when cutting.

Changing size: Automatically.

PLC cabinet: Siemens system.

Manual Decoiler

The manual decoiler is equipped with a brake device to adjust the tension of the core expansion ranging from φ490-510 mm and control the smoothness of the unociling process. The 1.9mm steel coil used in this case poses a risk of sudden poping open during the uncoiling process. To enhance safety, a press arm is installed to secure the steel coil, and protective blades made of steel are added to prevent steel coil slipping out. This design offers a cost-effective and high-safety solution.

The manual decoiler has no power. For higher production capacity requirements, we provide an optional hydraulic decoiler powered by a hydraulic station.

Guiding & Digital display

The primary function of guiding rollers is to maintain alignment between the steel coil and the machines, preventing distortion of the step beam and participating in part of the roll forming process to prevent rebound deformation of the steel. The straightness of the step beam is crucial for product quality and affects the load-bearing performance of the entire racking system. Guiding rollers are strategically placed not only at the beginning of the roll forming machine but also at various points along the entire roll forming line.

Digital display devices facilitate the convenient recording of the correct position of the guiding rollers. And measurements of the distance from each guiding roller to the left and right edges of the roll forming machine are recorded in the manual, allowing for easy adjustments based on these data even if slight displacements occur during transportation or production.

Leveler

Subsequently, the steel coil enters the leveler. With a coil thickness of 1.9mm, it's essential to eliminate the curvature of the steel coil, improving its flatness and parallelism for the quality of step beam. The leveler is equipped with 3 upper and 4 lower leveling rollers.

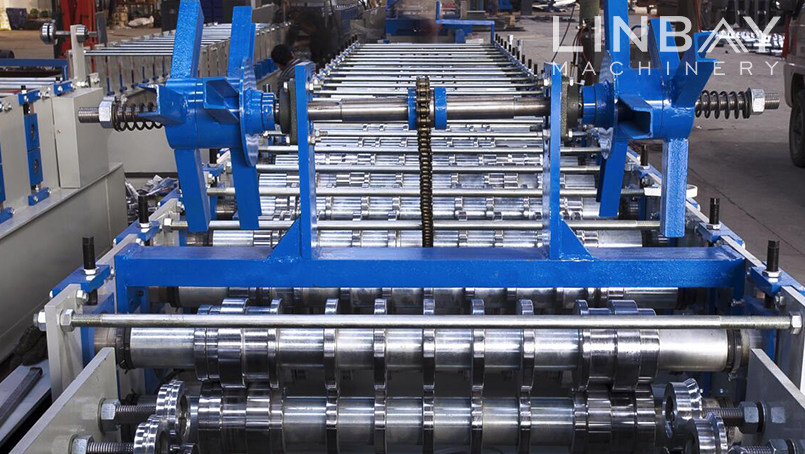

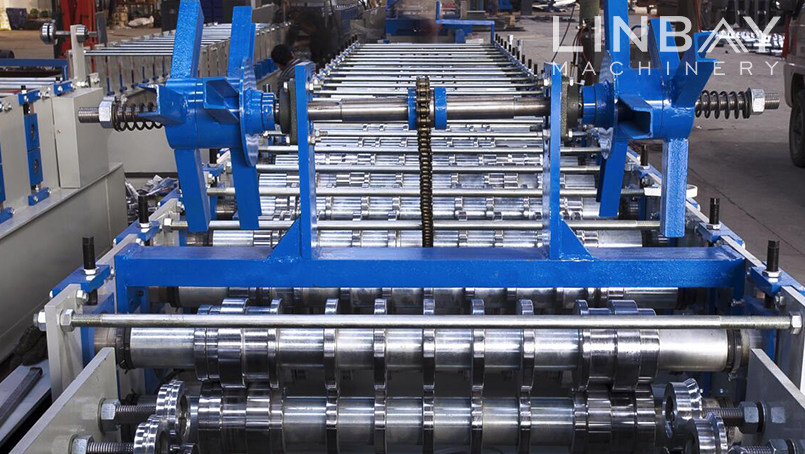

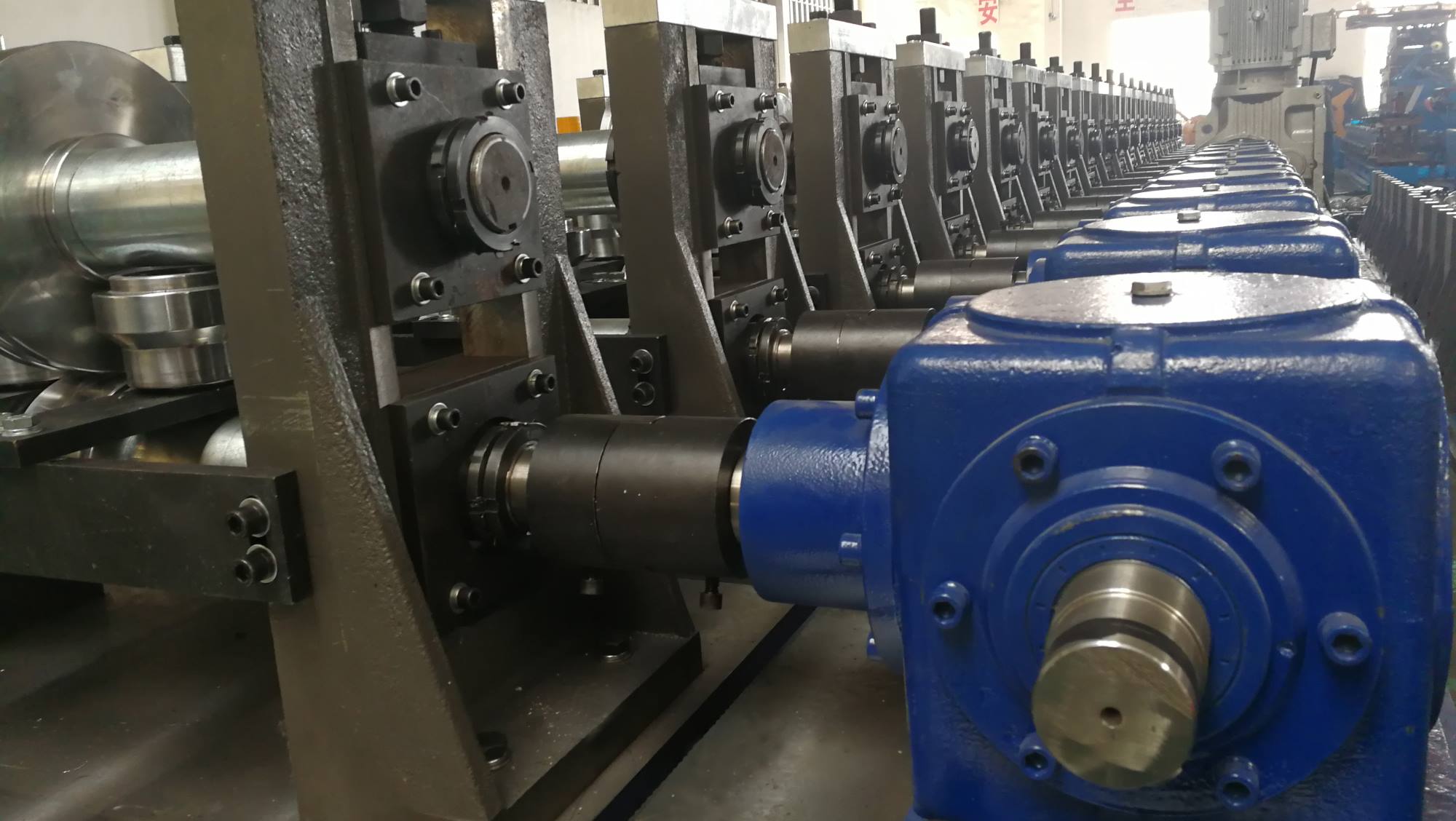

Roll Forming Machine

The roll forming machine is the most critical part of the entire production line, with variable speed control through a (Japanese brand) Yaskawa inverter ranging from 0 to 10m/min. This roll forming machine comprises 26 forming stations, utilizing a wall-panel structure and chain-driving system.

It can produce different sizes with a width of 66mm and a height ranging from 76.2 to 165.1mm. After the operator inputs the bottom width and height in the PLC control cabinet, the forming stations will automatically adjust to the accurate positions and change the key forming points (A and B points), taking approximately 10 minutes for the size changement. The height changes with the key forming points (A and B points) variation, enabling the production of step beams with different heights.

Gcr15 is used for the material of forming rollers, a high-carbon chromium-bearing steel known for its hardness and wear resistance. The rollers are chrome-plated for extended durability. The shafts, made of 40Cr material, undergo heat treatment for added strength.

Flying MIG Welder

To enhance the lifespan of the step beam and prevent separation at the steel coil joints, welding at the joints of steel coils in a dot pattern, with the spacing between each dot adjustable according to customer requirements. Two welding torches are installed to increase the line speed, and these torches can move simultaneously with the roll forming speed, ensuring continuous operation of the roll forming machine.

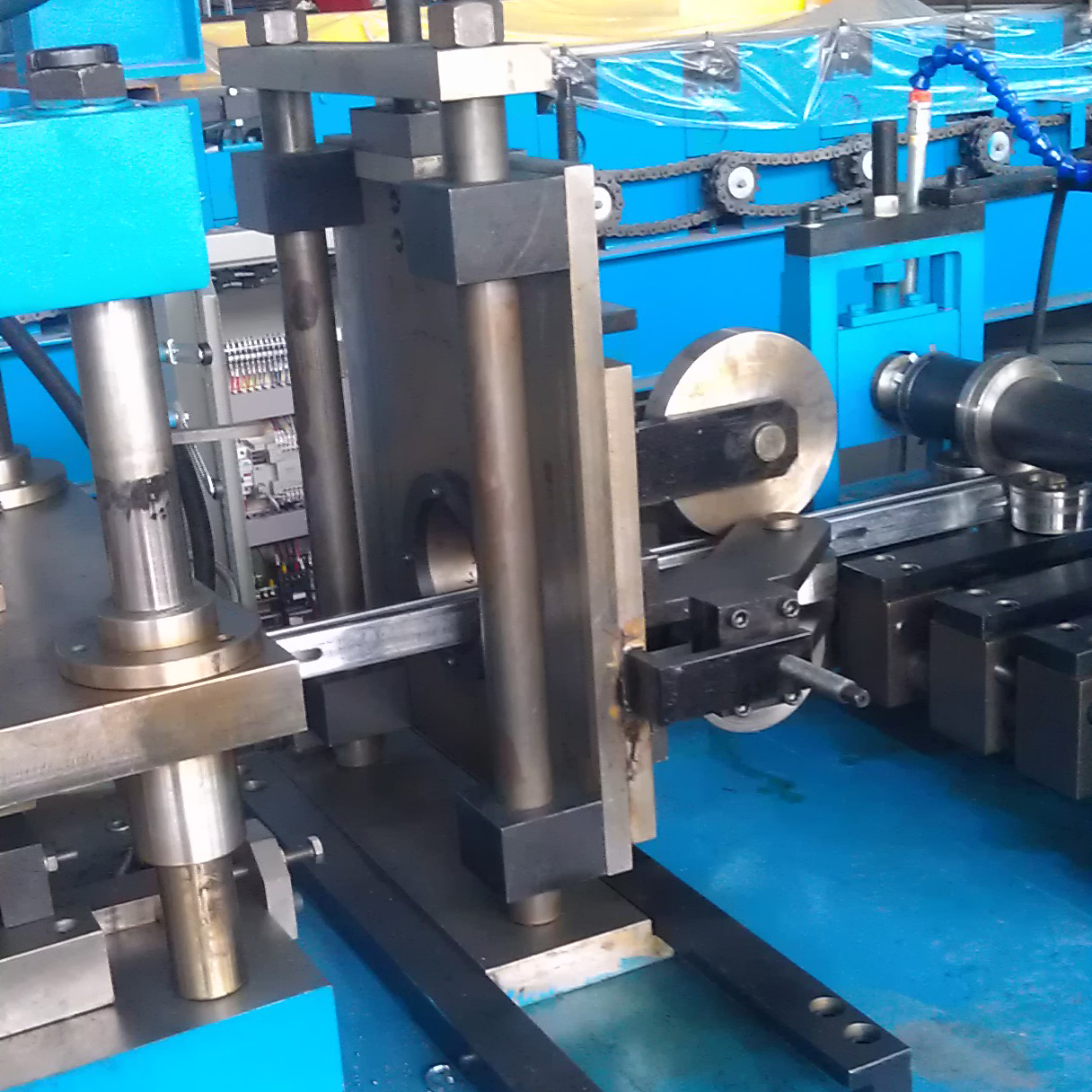

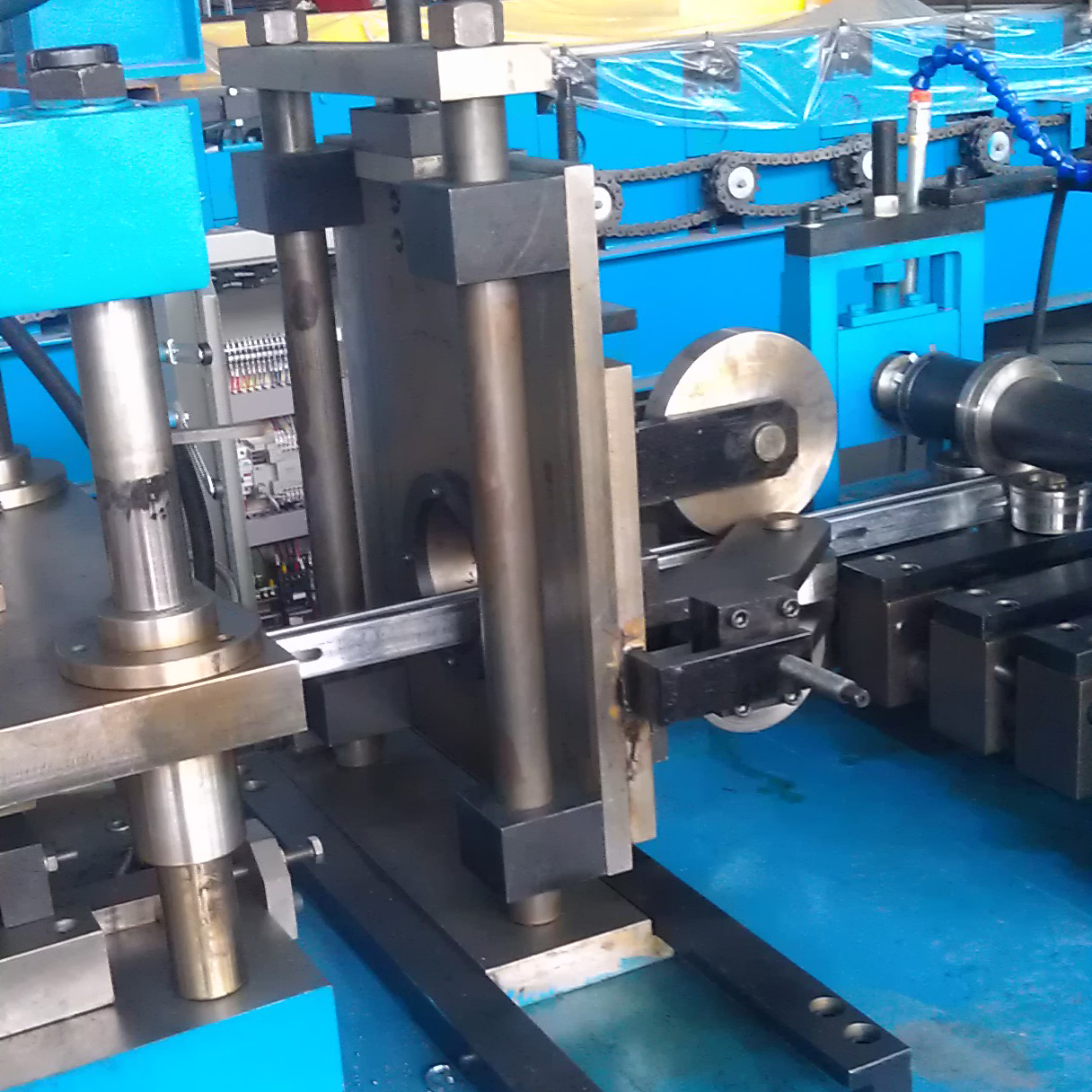

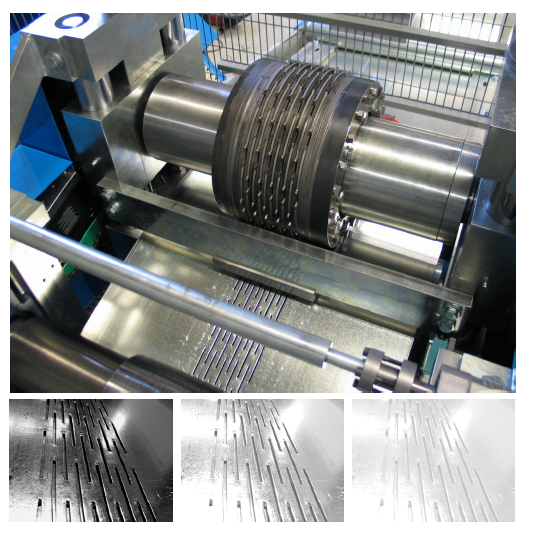

Flying Saw Cutting

After roll forming, the step beam enters the cutting machine, utilizing a saw cutting machine due to the closed shape of the step beam. Specialized saw blades ensure high precision and hardness, with a cooling sprayer to protect the saw blades, prolonging the lifespan of the saw blade. The saw cutting speed is slower than hydraulic shearing, but we've set a mobile function to match the roll forming machine's production speed, ensuring continuous operation of the roll forming machine. And the saw cutting machine ensures no waste during steel coil replacement and profile cutting.

Encoder & PLC

A Japanese Koyo encoder in the roll forming machine converts the sensed coil length into an electrical signal transmitted to the PLC control cabinet. A motion controller is installed inside the electrical control cabinet, ensuring no acceleration or deceleration during the forward and backward movement of the cutting machine, thus achieving precise cutting length accuracy. Additionally, the welding marks are stable and smooth, preventing the step beams from cracking, and resulting in a stable and high-quality production. The PLC screen allows operators to control production speed, set production dimensions, cutting length, etc. The PLC control cabinet has a memory storage function for commonly used parameters and offers protection functions such as overload, short circuit, and phase loss.

The language on the PLC screen can be customized according to the customers' requirements.

Hydraulic Station

Our hydraulic station features a cooling electric fan to efficiently dissipate heat, ensuring prolonged and reliable operation with low failure rates.

Warranty

Upon shipment, the delivery date is indicated on the steel nameplate, providing a two-year guarantee for the entire production line and a five-year warranty for rollers and shafts.

Description:

This step beam roll forming production line was installed in Mexico, 2016, using a flying saw cut and cooling system. It produces three sizes in one machine by changing sleeves manually.

|

Pallet Rack Step beam Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):1.5-2.0 |

|

B) PPGI |

||

|

C) Cold-rolled Steel |

||

|

D) Stainless Steel |

||

|

E) Aluminum |

||

|

F) Carbon steel |

||

|

Yield strength : |

250 - 350 Mpa |

|

|

Tensil stress : |

350 Mpa-500 Mpa |

|

|

Nominal forming speed(M/MIN) |

10-20 |

* Or according to your requirement |

|

Forming station : |

26 |

* According to your profile drawings |

|

Decoiler : |

Hydraulic decoiler |

* Double head decoiler (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

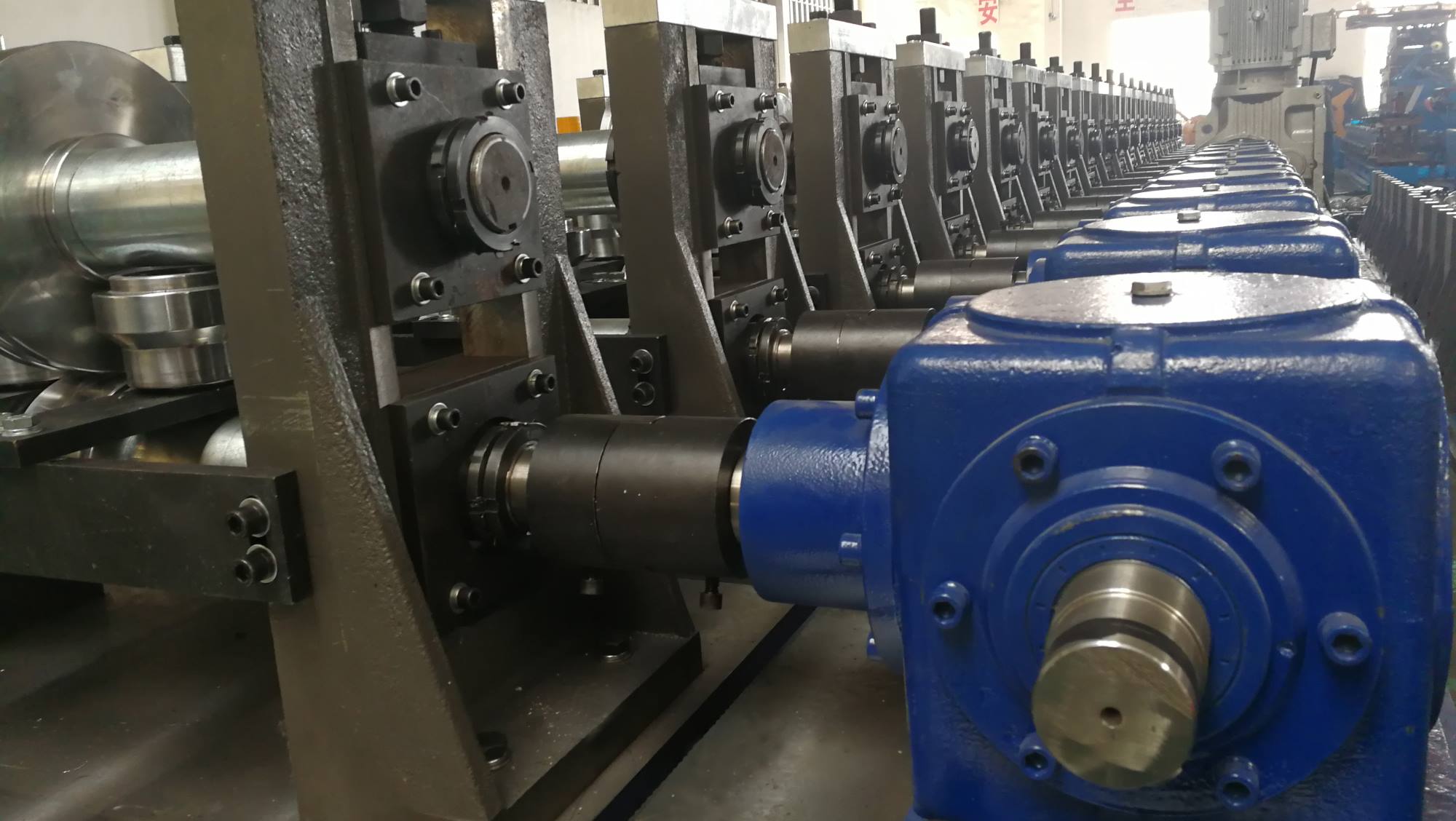

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Torri stands |

* Cast iron stands (Optional) |

|

Rollers’ material : |

GCr 15 |

* SKD-11 (Optional) |

|

Cutting system : |

Saw cut |

* Flying cut (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Siemens |

|

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1.Q: What kinds of experience do you have in producing pallet rack roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2.Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. One machine could produce several profiles, we would check your profile drawings to meet your needs. We are dedicated to provide cost-effective solutions.

3.Q: What is delivery time of step beam roll forming machine?

A: 80 days to 100 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

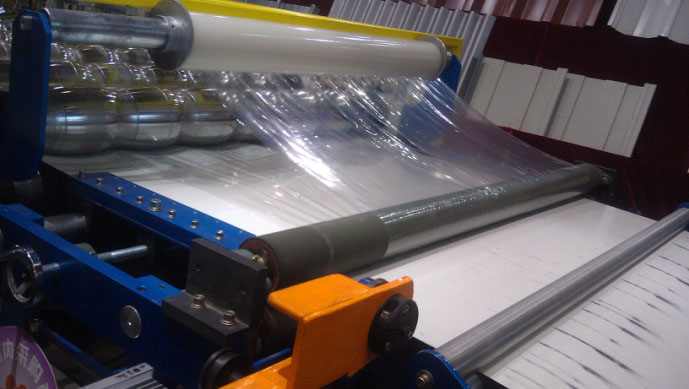

Others

-

scrap collector

-

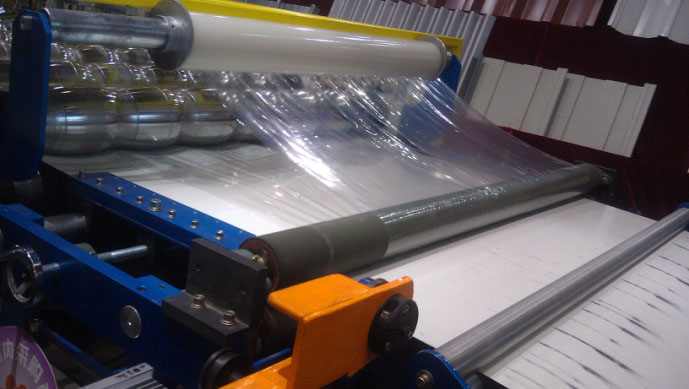

pasting

-

mould change

-

guiding head

-

-

Out table

-

Non-powered

-

auto stacker

-

-

Cutting

-

Sawing cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for C purlin

-

-

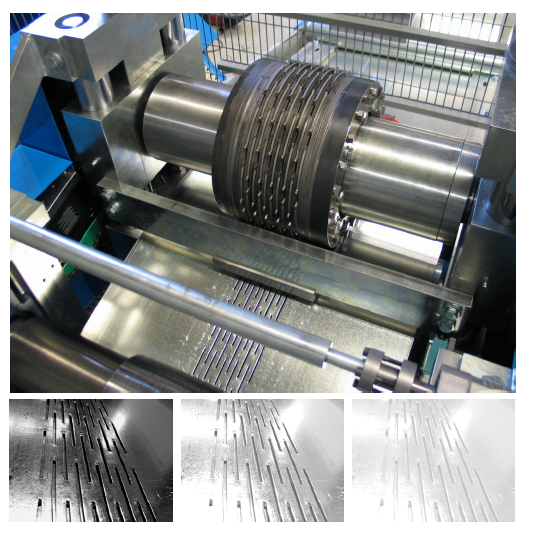

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

Manual decoiler

-

hydraulic decoiler

-

double head decoiler

-