Automatic size adjustment-Step Beam Roll Forming Machine

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)

Step beams are a fundamental component in various industrial and construction applications. They play a vital role in providing structural support and stability to shelving systems, racks, and mezzanine floors. Step beams are typically made of high-quality steel and are designed with a unique step-like profile that allows for easy attachment of accessories like wire decking, pallet supports, and beam connectors.

These beams come in a range of heights, widths, and load capacities, making them versatile for accommodating different storage needs. With their robust construction and ability to distribute weight evenly, step beams ensure the safe and efficient storage of heavy loads.

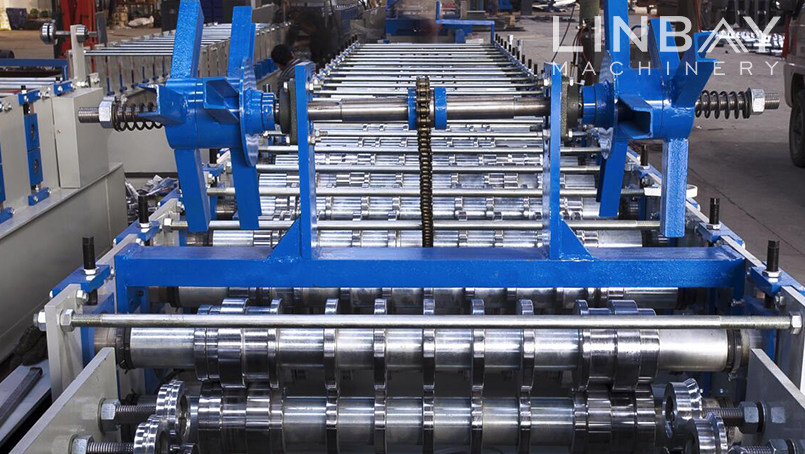

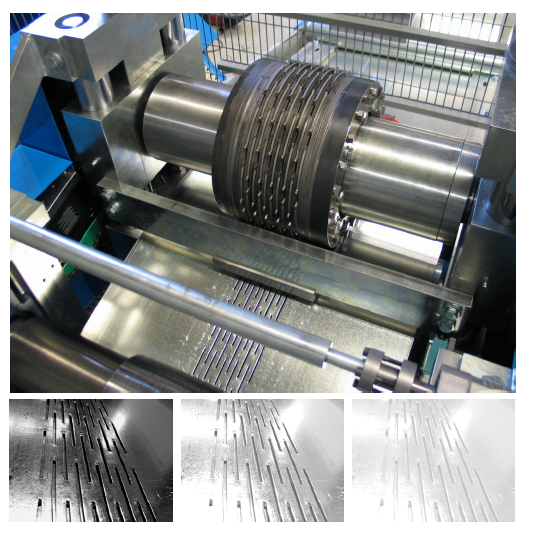

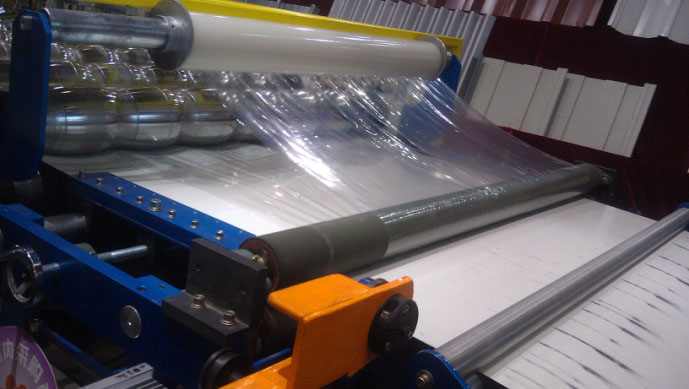

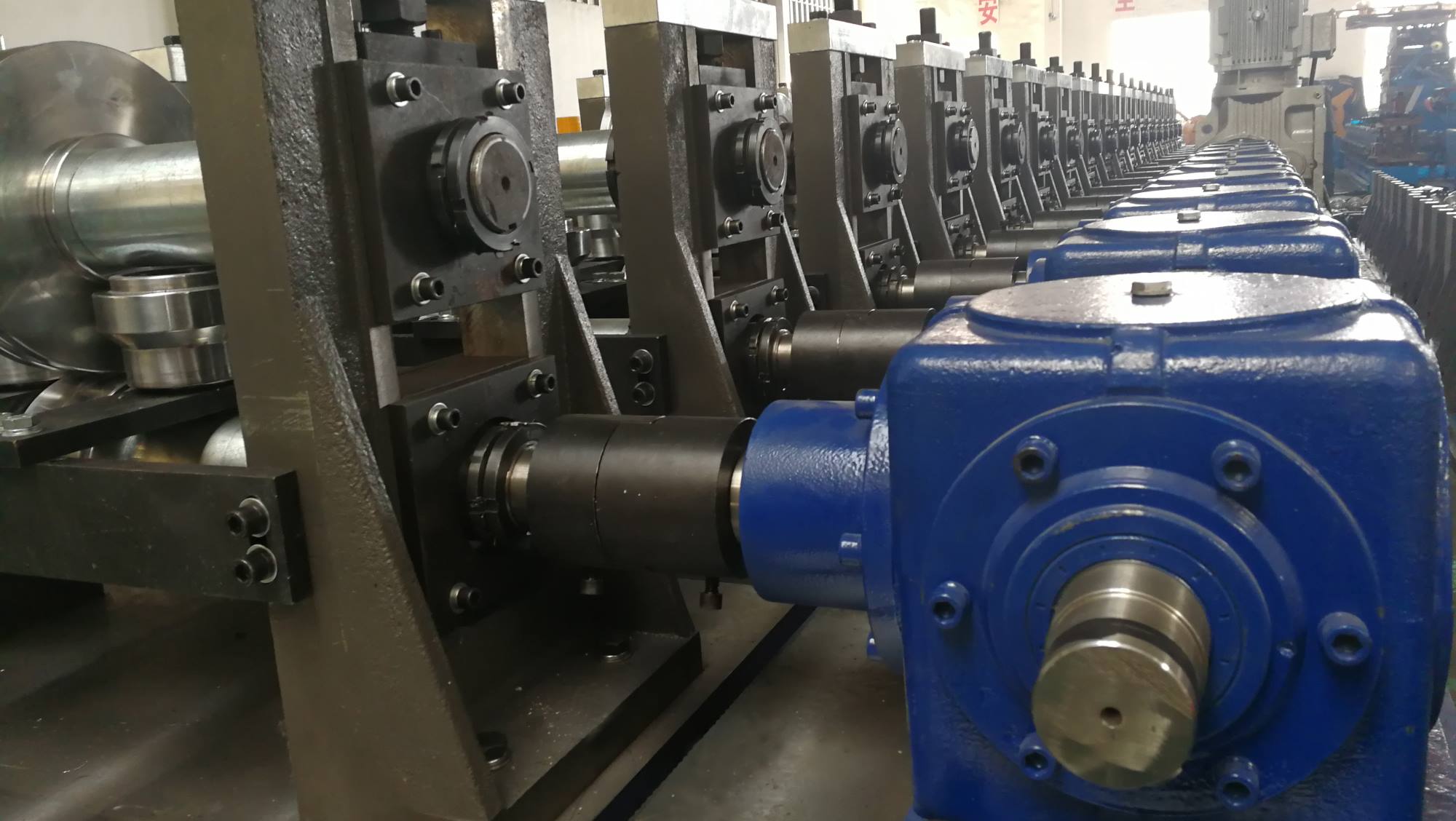

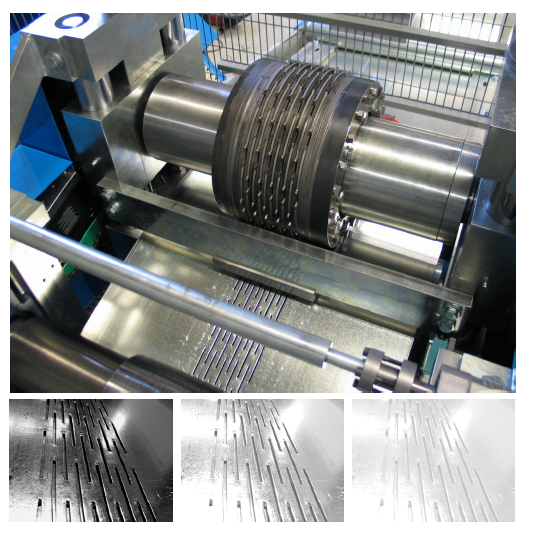

In a production setting, a step beam roll forming machine is used to manufacture these essential components. The roll forming process involves feeding steel coils into the machine, which then gradually shapes and forms the metal into precise step beam profiles. The roll forming machine allows for seamless and continuous production, ensuring consistent quality and high output rates.

Step beams have become an indispensable part of modern warehousing, distribution centers, and logistics facilities. Their durability, ease of installation, and flexibility in supporting various storage systems have made them a preferred choice for professionals in the industry. Whether it's in traditional pallet racking systems or innovative storage solutions, step beams contribute to efficient space utilization and optimized material handling processes.

Description:

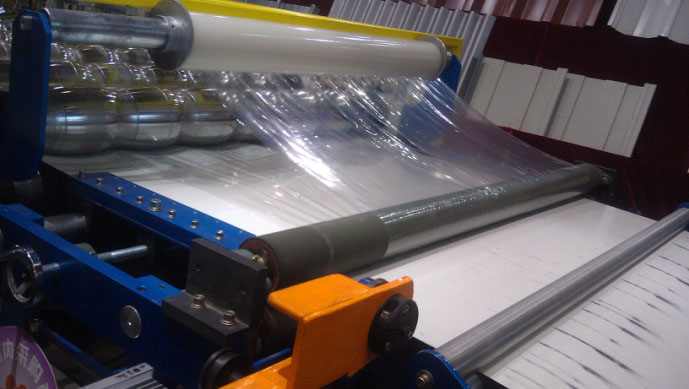

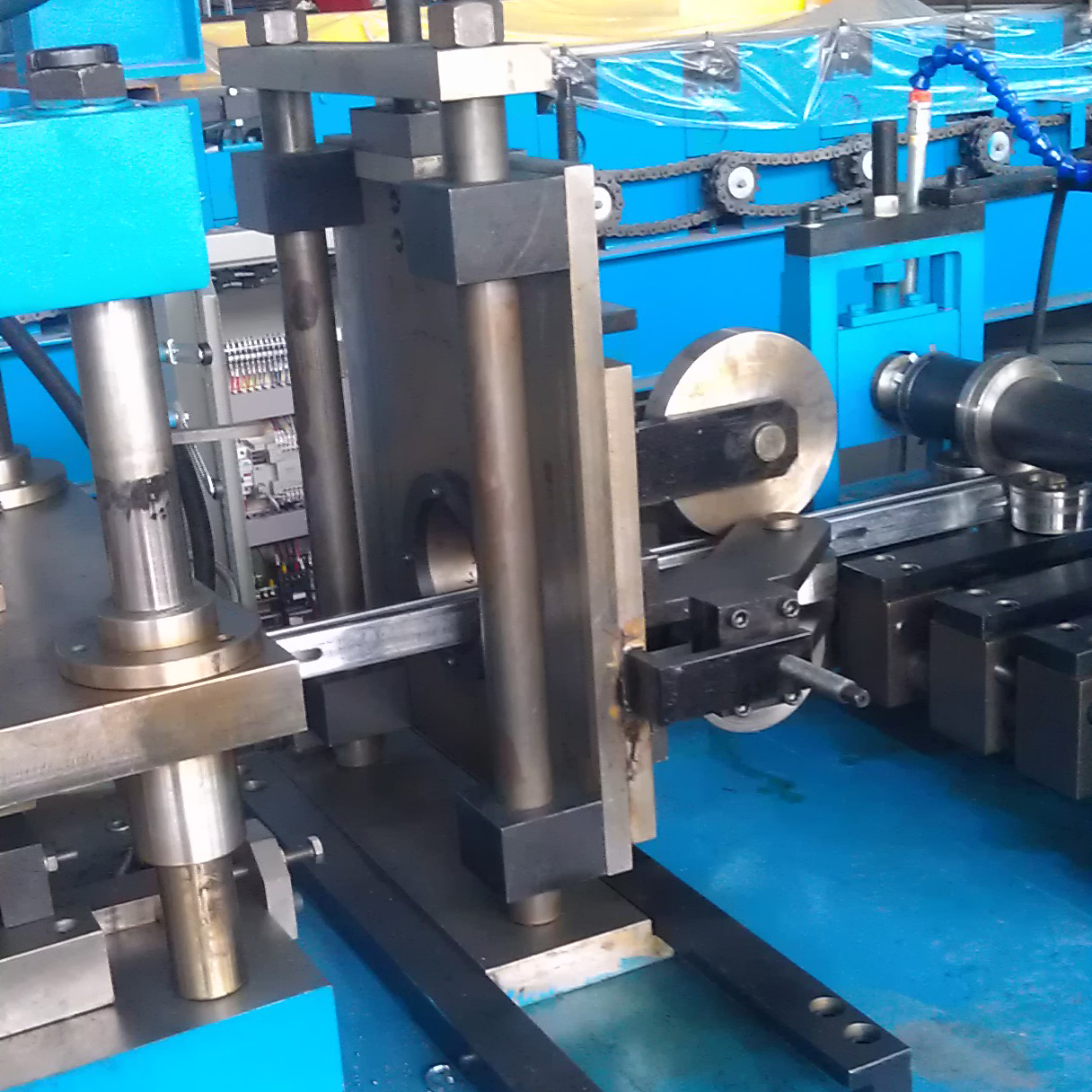

Back in 2016, we installed this remarkable step beam roll forming production line in Mexico. One of its standout features is the utilization of a flying saw cut and cooling system, ensuring precision and efficiency during the manufacturing process. With the ability to produce three different sizes in a single machine, this production line offers enhanced versatility, achieved by easily changing sleeves manually. Its seamless operation and reliable performance have made it a valuable asset for our clients in Mexico's industrial sector.

|

Pallet Rack Step beam Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):1.5-2.0 |

|

B) PPGI |

||

|

C) Cold-rolled Steel |

||

|

D) Stainless Steel |

||

|

E) Aluminum |

||

|

F) Carbon steel |

||

|

Yield strength : |

250 - 350 Mpa |

|

|

Tensil stress : |

350 Mpa-500 Mpa |

|

|

Nominal forming speed(M/MIN) |

10-20 |

* Or according to your requirement |

|

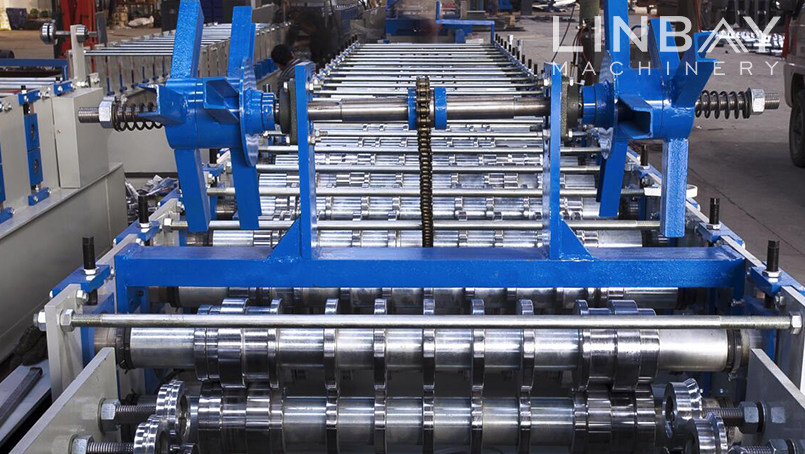

Forming station : |

26 |

* According to your profile drawings |

|

Decoiler : |

Hydraulic decoiler |

* Double head decoiler (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

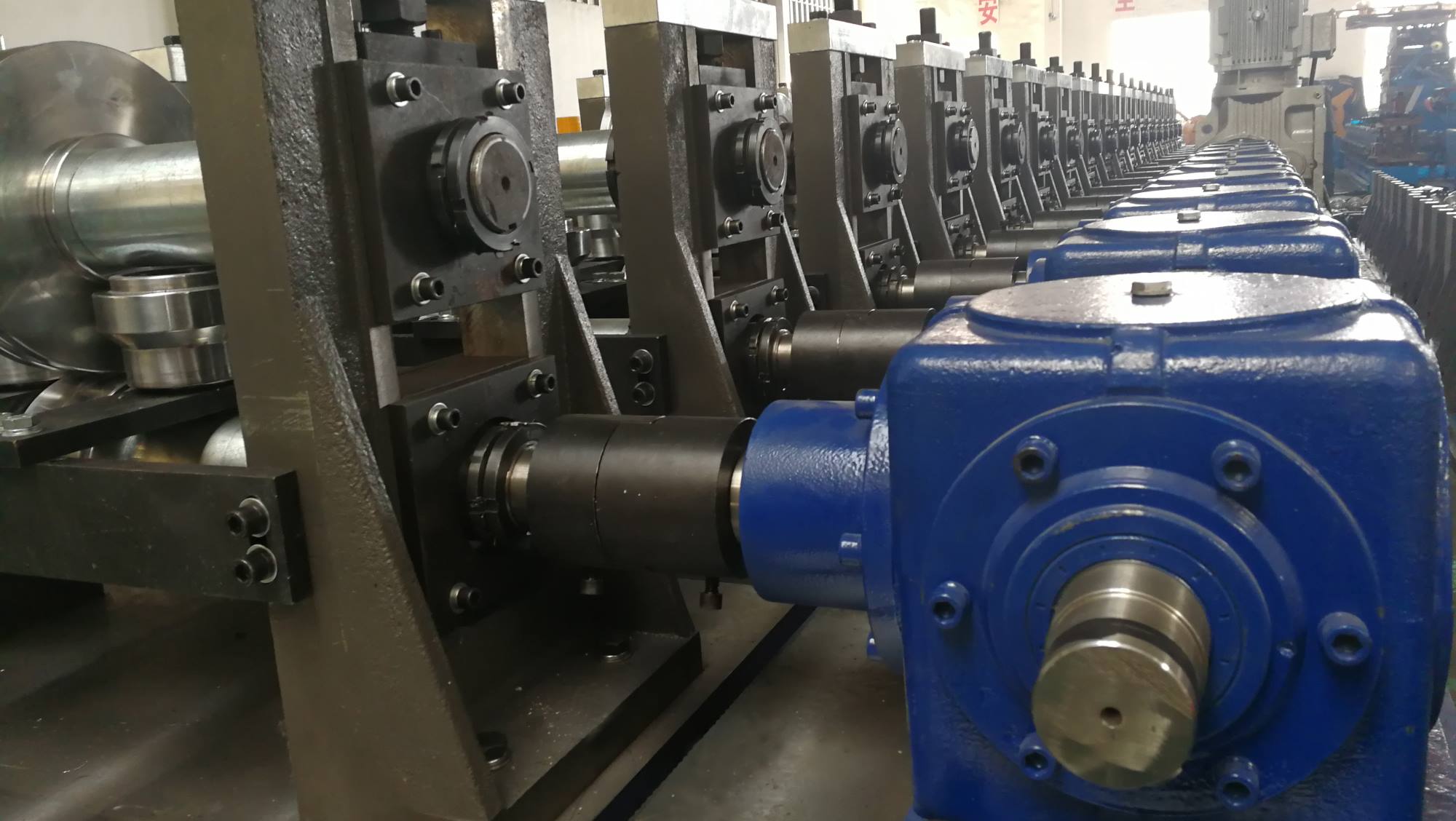

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Torri stands |

* Cast iron stands (Optional) |

|

Rollers’ material : |

GCr 15 |

* SKD-11 (Optional) |

|

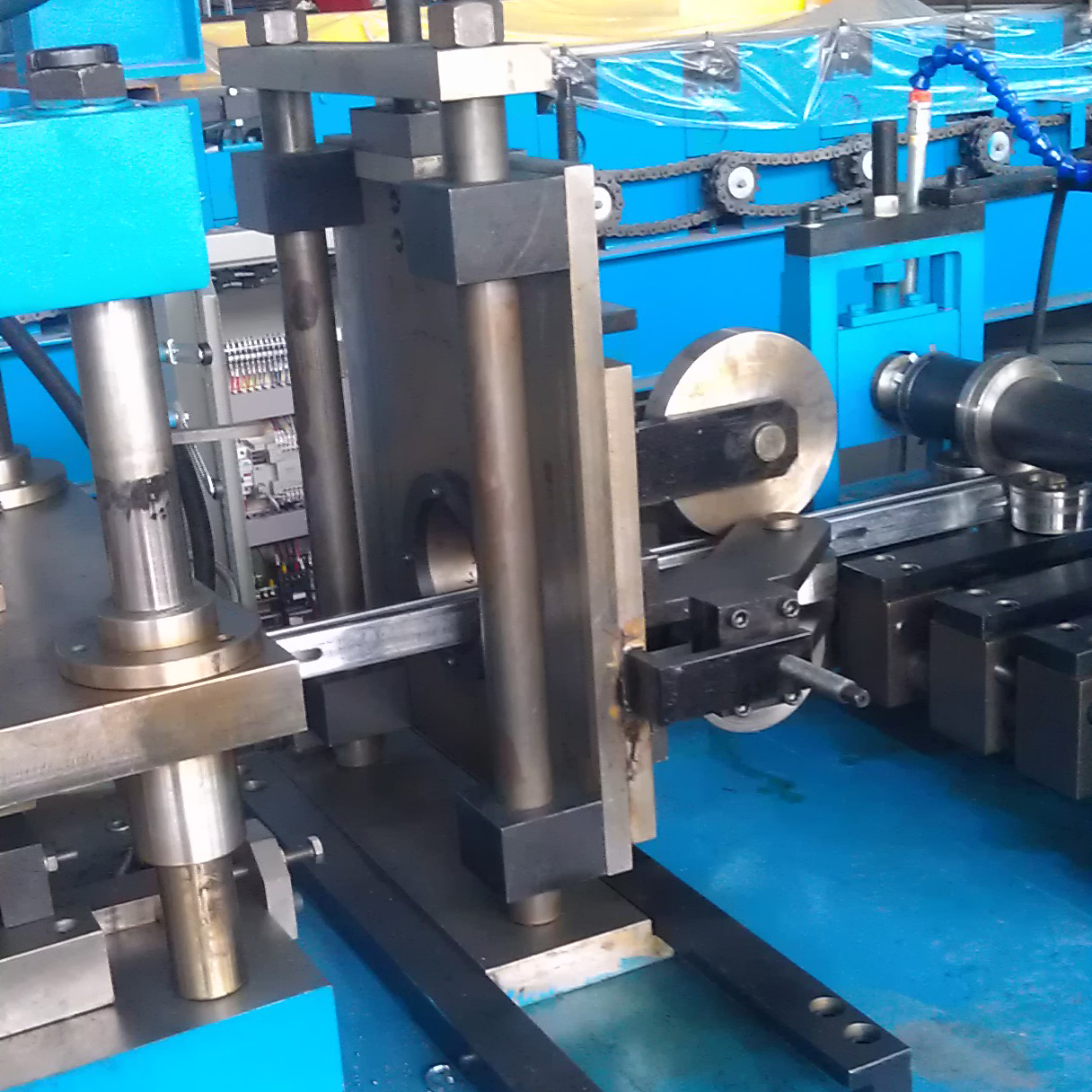

Cutting system : |

Saw cut |

* Flying cut (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Siemens |

|

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1.Q: What kinds of experience do you have in producing pallet rack roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2.Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. One machine could produce several profiles, we would check your profile drawings to meet your needs. We are dedicated to provide cost-effective solutions.

3.Q: What is delivery time of step beam roll forming machine?

A: 80 days to 100 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Others

-

scrap collector

-

pasting

-

mould change

-

guiding head

-

-

Out table

-

Non-powered

-

auto stacker

-

-

Cutting

-

Sawing cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for C purlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

Manual decoiler

-

hydraulic decoiler

-

double head decoiler

-