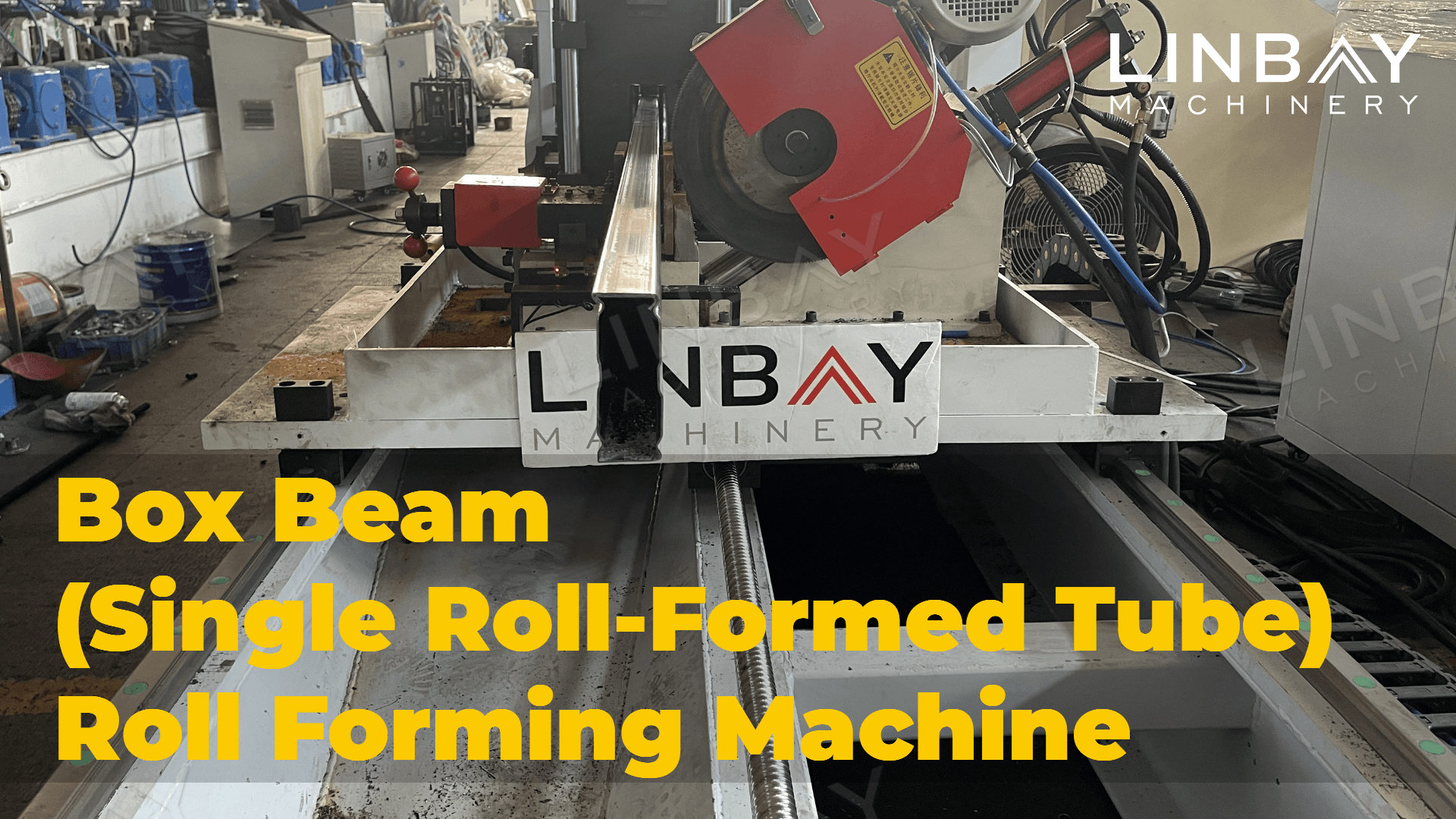

Tubular Beam(A Single Roll-Formed Tube) Roll Forming Machine

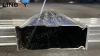

A one-piece beam is a type of racking beam with a cross-section resembling a rectangular box. The box beam, crucial for heavy-duty racks, is connected using connecting plates, screws, with rack uprights, as a robust framework. This design enhances the stability and robustness of the shelves, enabling them to withstand significant loads.

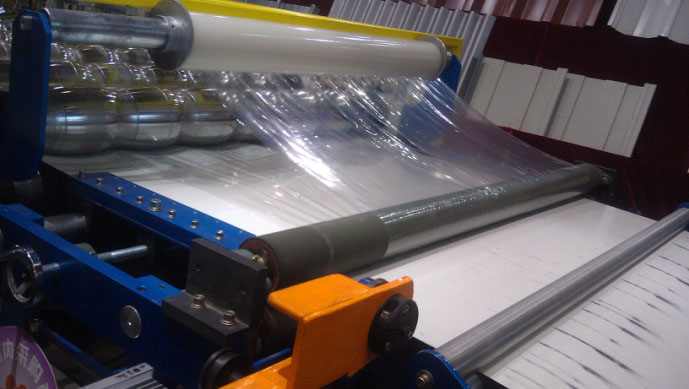

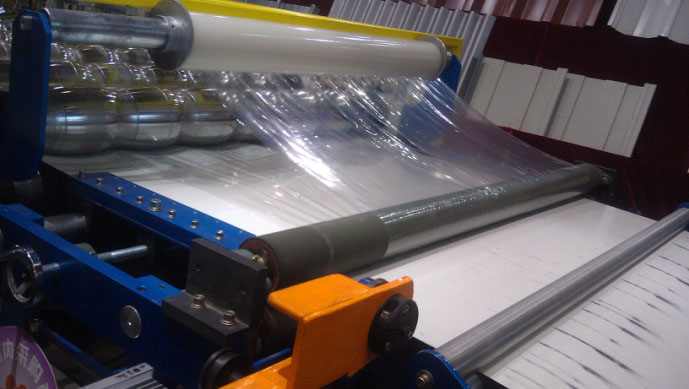

In this particular instance, the one-piece box beam is crafted from a single steel coil. Typically, cold rolled steel, hot rolled steel and galvanized steel with a thickness of 1.5-2mm is used for production.

Real case-Main Technical Parameters

Flow chart

Manual decoiler--Guiding--Leveler--Roll forming machine--Flying saw cut--Out table

Main Techinical Parameters

- Line speed: 5-6meters/min dependes on the cutting length

- Profiles: Multiple sizes-same height of 50mm, and different width of 100, 110, 120, 130, 140mm

- Material thickness:1.9mm (in this case)

- Suitable material:Hot rolled steel, cold rolled steel, galvanized steel

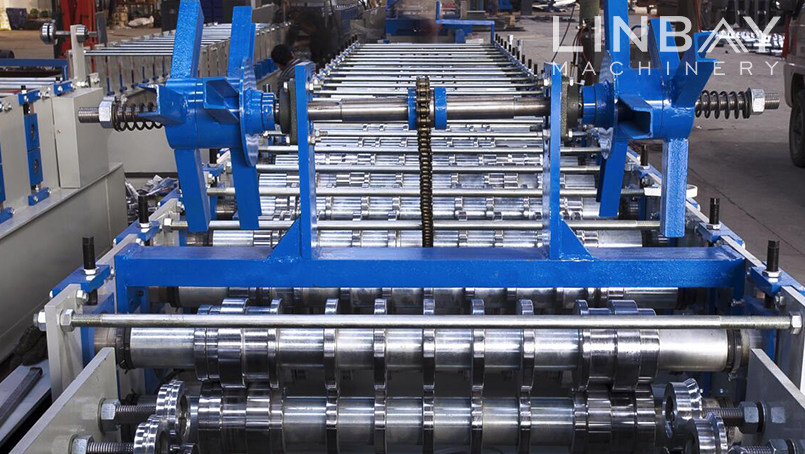

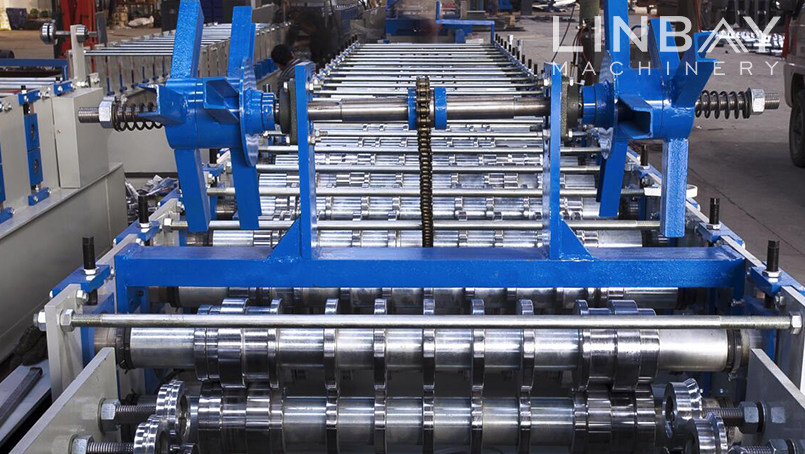

- Roll forming machine: Cast-iron structure and chain driving system.

- Of forming station: 28

- Cutting system: Saw cutting, roll former doesn’t stop when cutting.

- Changing size: 10 minutes automatically.

- PLC cabinet: Siemens system.

Real case-Description

Manual Decoiler

The manual decoiler is equipped with a brake device to adjust the expansion ranging from φ460-520 mm and control the smoothness of the uncoiling process. A press arm is set to avoid the steel coil bulk. Additionally, steel protection leaves are installed to prevent coil slippage during uncoiling. This design ensures high cost-effectiveness and safety.

In this case, a manual decoiler without its own power source is utilized. For higher production capacity demands, we offer an optional hydraulic decoiler powered by a hydraulic station.

Guiding

Guiding rollers play a critical role in maintaining alignment between the steel coil and the machine, preventing distortion of the tube beam. They also contribute to the forming process, averting rebound deformation of the steel coil. The straightness of the tube box beam is crucial for product quality, impacting the load-bearing performance of the racking system. Guiding rollers are strategically placed along the entire forming line to ensure precise positioning. Measurements of each guiding rollers to the edge are meticulously recorded in the manual, facilitating easy adjustments based on this data, even if slight displacements occur during transportation or production.

Leveler

Moving forward, the steel coil enters the leveler. The leveler efficiently eliminates the curvature of the steel coil, enhancing its flatness and parallelism for superior quality in the final product. The leveler is equipped with 3 upper and 4 lower leveling rollers.

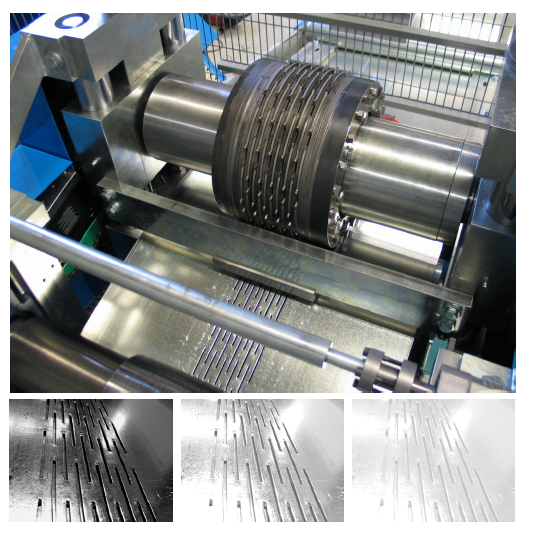

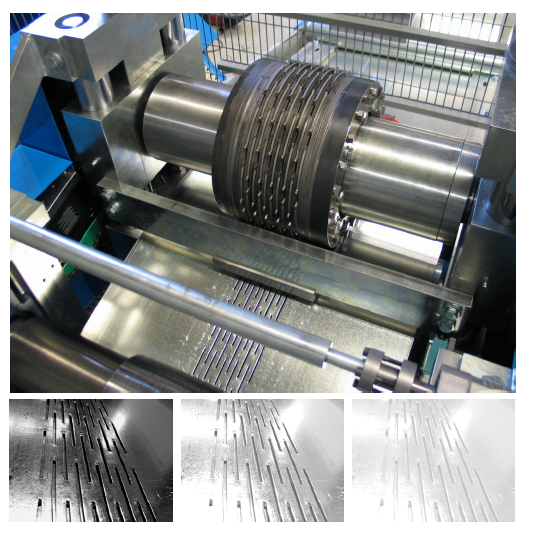

Roll Forming Machine

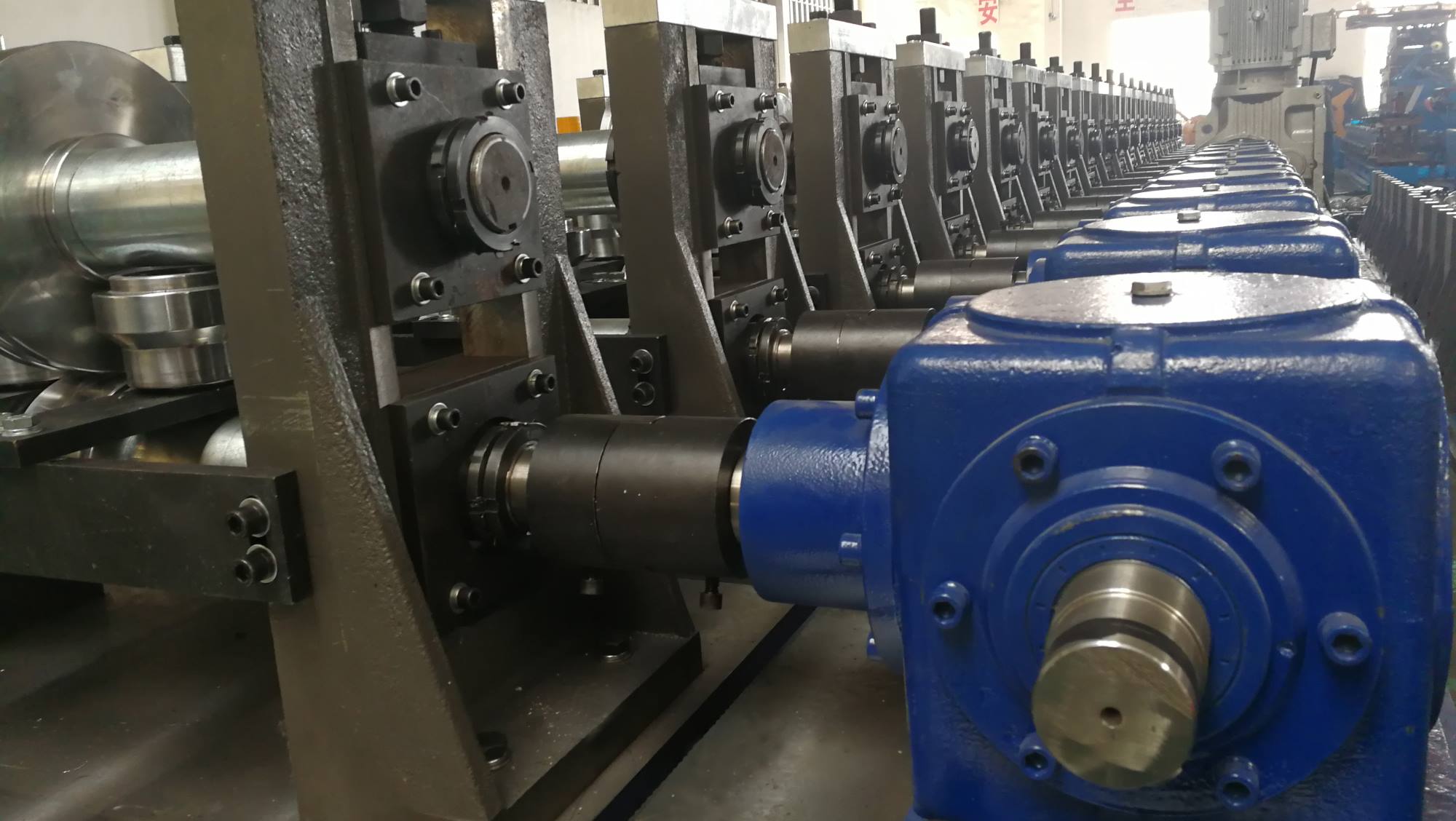

The roll forming machine is the most important part of the entire production line, featuring 28 sets of forming stations with a cast-iron structure made from a whole piece solid steel. Driven by a robust chain system, this machine produces various sizes with the uniform height and different width of 100, 110, 120, 130, 140mm. Workers easily input planned sizes on the PLC control screen, allowing for automatic adjustment of forming stations to precise positions. The automated size change process takes approximately 10 minutes. The movement of forming stations on the rail adjusts the positions of the 4 key forming points, enabling the production of box beams with different widths.

Gcr15 is the selected material for forming rollers, a high-carbon chromium-bearing steel renowned for its hardness and wear resistance. The rollers undergo chrome-plating for extended durability, while the shafts, made of 40Cr material, undergo meticulous heat treatment.

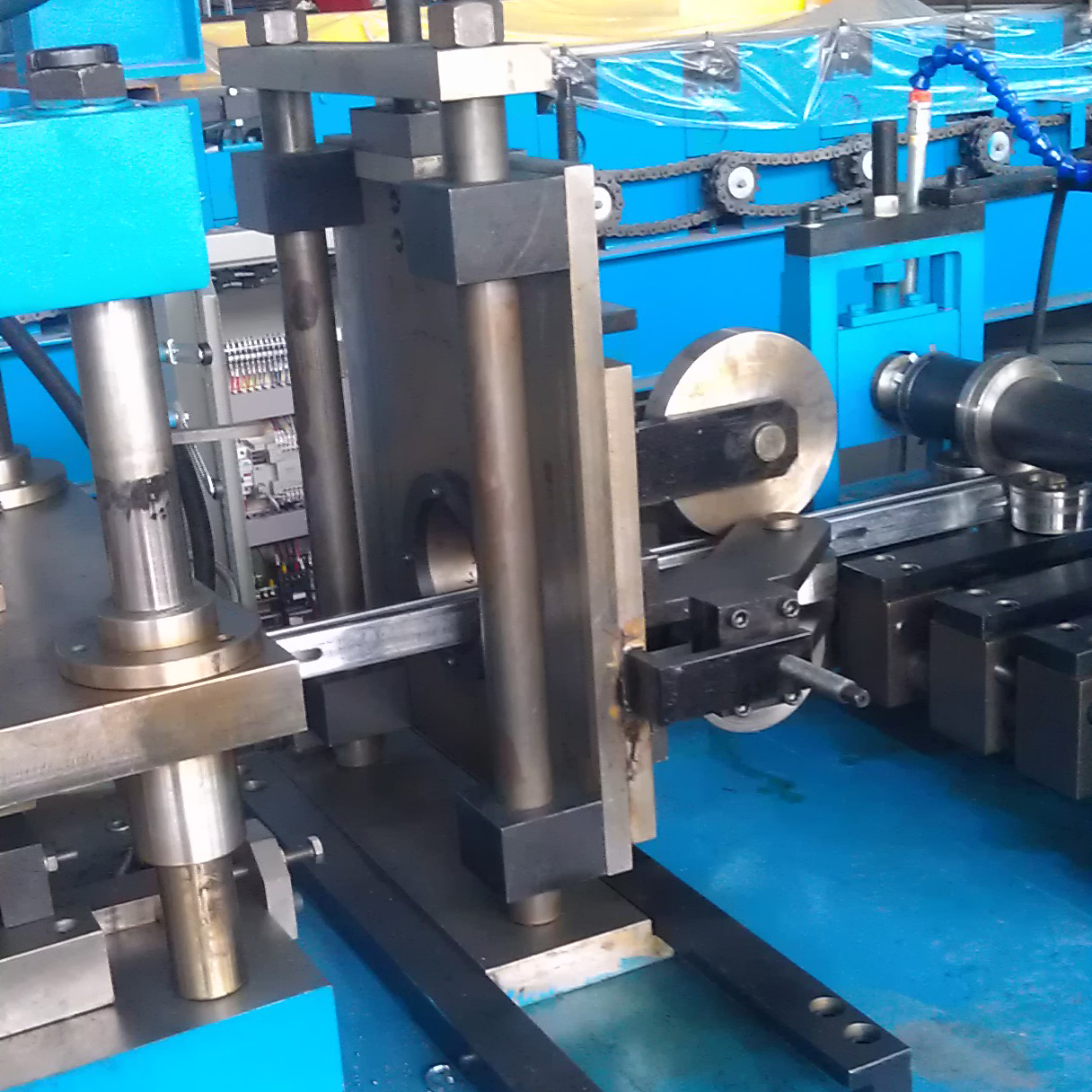

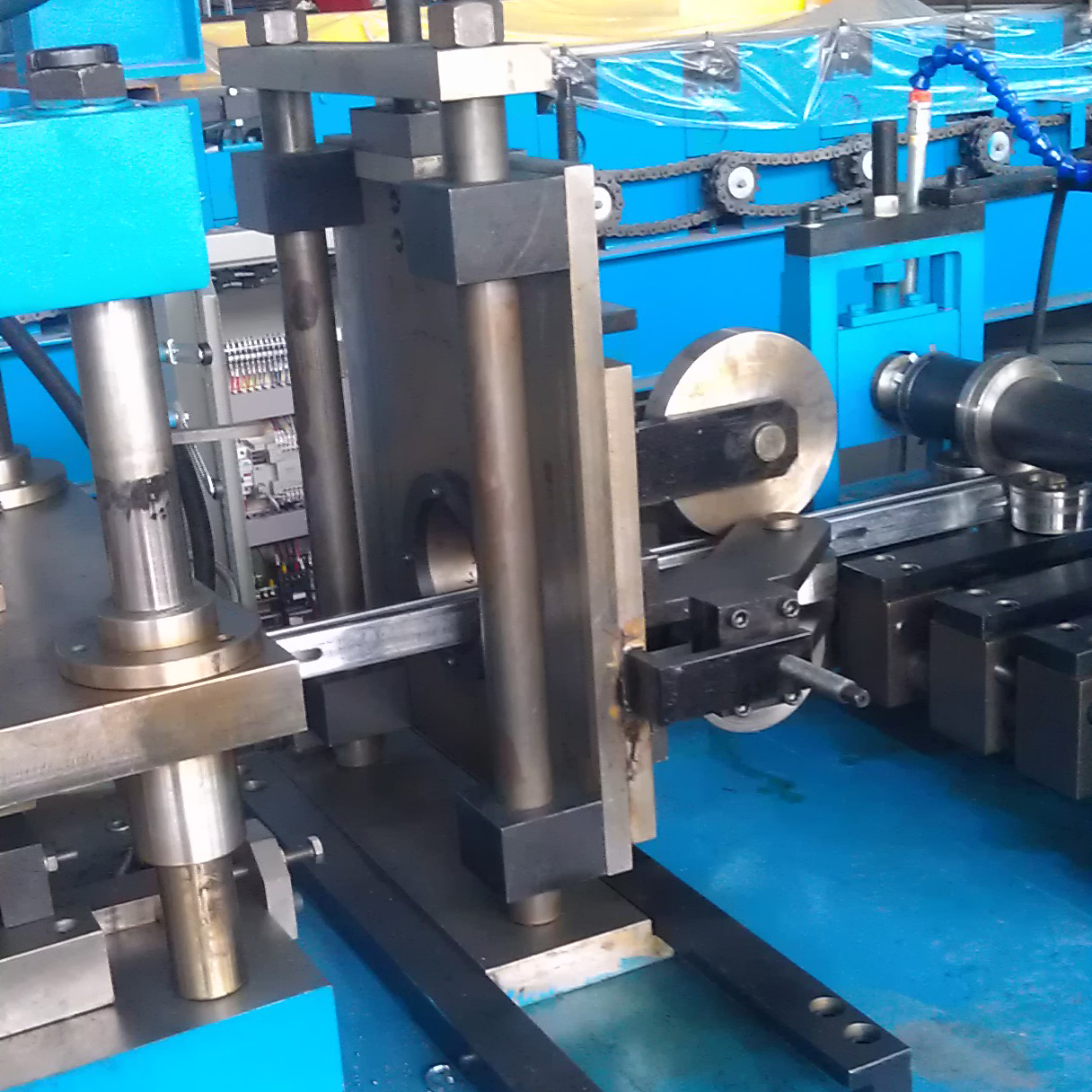

Flying Saw Cut

The cross-section of the box beam takes on a closed shape, necessitating the use of a saw cutting to prevent deformation of the cut edges under stress. Saw cutting minimizes steel coil waste, providing smooth cutting surfaces without burrs. Professional saw blades ensure high precision and hardness. Additionally, a cooling nozzle protects and extends the lifespan of the saw blades, preserving their high physical properties for continuous and efficient operation.

While the saw cutting speed is marginally slower than hydraulic shearing, we've set a mobile function to synchronize with the forming machine's production speed, ensuring uninterrupted operation.

Encoder & PLC

A Japanese Koyo encoder within the roll forming machine converts sensed coil lengths into electrical signals transmitted to the PLC control cabinet. This ensures cutting errors are controlled within 1mm, guaranteeing the production of high-quality products and avoiding waste from incorrect cuts. The operators can set production speed, profile dimensions, cutting length, the number of productions, etc on the PLC control cabinet screen.

The PLC cabinet has memory storage function for commonly used parameters, operators don’t have to re-enter parameters before each production. The language on the PLC screen can be customized based on customer preferences.

Hydraulic Station

Our hydraulic station, equipped with cooling electric fans, efficiently dissipates heat, ensuring prolonged and reliable operation with a low failure rate.

Warranty

On the day of shipment, the current date will be engraved on the metal nameplate, marking the commencement of a two-year guarantee for the entire production line and a five-year warranty for rollers and shafts.

Single Roll-Formed box beam VS Double C-Shape box beam

- Load-bearing capacity: The single roll-formed beam is less than the double C-shape beam in terms of load-bearing capacity. This is because the single roll-formed beam has only two layers of overlap on the upper width, while the double C-shape beam has two layers of overlap on both upper and lower widths.

- Production Speed: The single roll-formed beam operates at a speed of 5-6m/min, while the double C-Shapebeam operates at 0-4m/min.

- Raw Material Usage: For the same dimensions, the double C-Shapebeam requires more material than the single roll-formedbeam, equivalent to the additional material in the area of bottom width multiplied by length.

- Cutting Machine: The single roll-formed beam utilizes saw cutting, suitable for cutting beams of various sizes. The double C-shape beam employs hydraulic diagonal cutting, requiring a specific blade for each size.

- Production Line Layout: For reference only. The length of the single roll-formedbeam production line is 26050mm, while the double C-Shapebeam production line is 33367mm. The single roll-formed beam production line has simpler processes: uncoiling, forming, cutting, and discharge. The double C-shape beam production line involves additional steps: uncoiling, forming, cutting, transport platform, interlocking, and discharge. However, both lines only require one worker for supervision, with the main difference being the significant disparity in length.

- Price: For the same multi-size automatic transverse movement solution, the production cost of the double C-shape beam line is slightly lower than that of the single roll-formed beam line.

|

Pallet Rack Box Beam Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):1.5-2.0 |

|

B) PPGI |

||

|

C) Cold-rolled Steel |

||

|

D) Stainless Steel |

||

|

E) Aluminum |

||

|

F) Carbon steel |

||

|

Yield strength : |

250 - 350 Mpa |

|

|

Tensil stress : |

350 Mpa-500 Mpa |

|

|

Nominal forming speed(M/MIN) |

10-20 |

* Or according to your requirement |

|

Forming station : |

18-20 |

* According to your profile drawings |

|

Decoiler : |

Manual decoiler |

* Hydraulic decoiler (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

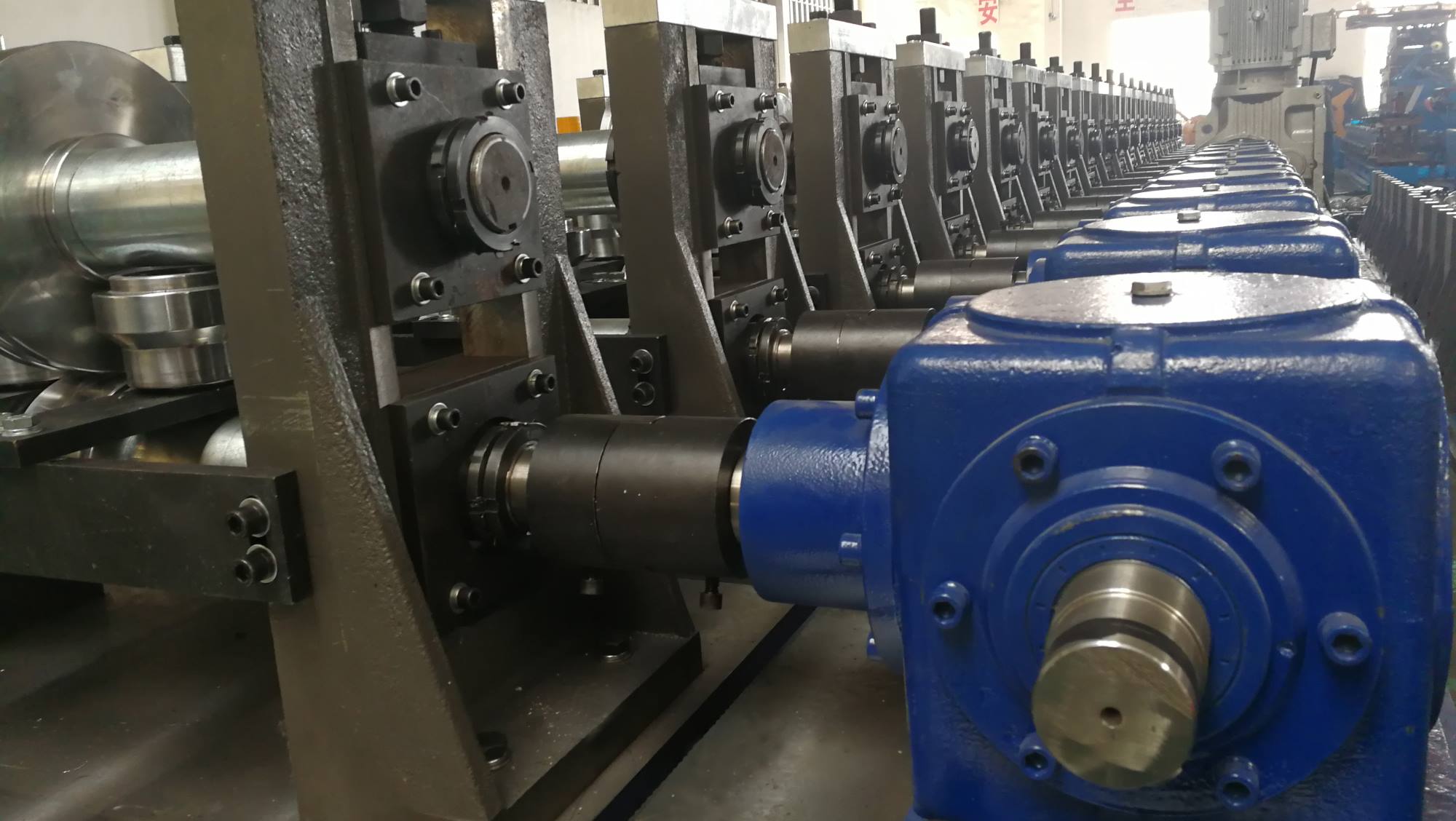

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Torri stands |

* Cast iron stands (Optional) |

|

Rollers’ material : |

GCr 15 |

* SKD-11 (Optional) |

|

Cutting system : |

Hydraulic cut |

* Flying cut (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Siemens |

|

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1.Q: What kinds of experience do you have in producing pallet rack roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2.Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. One machine could produce several profiles, we would check your profile drawings to meet your needs. We are dedicated to provide cost-effective solutions.

3.Q: What is delivery time of box beam roll forming machine?

A: 80 days to 100 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Others

-

scrap collector

-

pasting

-

mould change

-

guiding head

-

-

Out table

-

Non-powered

-

auto stacker

-

-

Cutting

-

Sawing cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for C purlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

Manual decoiler

-

hydraulic decoiler

-

double head decoiler

-