.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

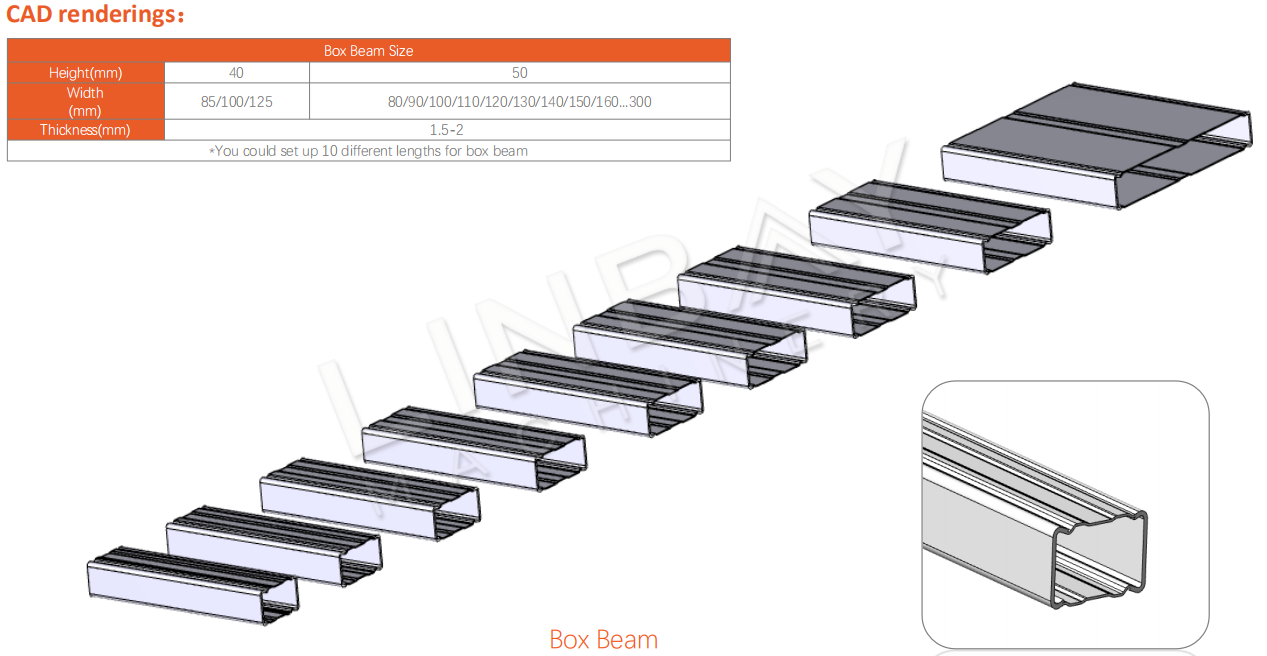

Box beams are integral components within rack systems, typically fabricated from hot-rolled steel or cold-rolled steel, with thickness ranging from 1.5mm to 2mm. Traditionally, box beams were manually welded after roll forming. However, our innovative approach utilizes a fully automatic production line, employing a seaming machine to seamlessly combine 2 individual profiles into box beams. This roll forming machine can produce different sizes and thicknesses of box beams through automatic adjustments.

Flow chart

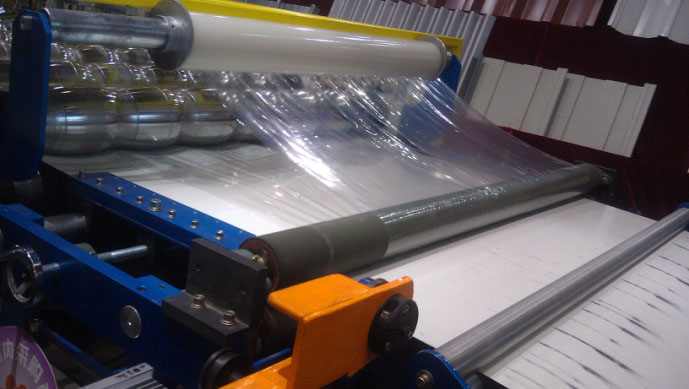

Decoiler

We install press-arm on the decoiler to press the steel coil to secure the coil during replacements, preventing any sudden release that could potentially harm workers. Additionally, we incorporate protective iron-leaves to prevent steel coils from slipping during the uncoiling process. This design not only safeguards workers but also ensures the protection of both the steel coils and the machines.

Leveler

The leveling machine, an essential component in the production process, effectively removes any irregularities from the steel coil, enhancing its flatness and parallelism. This also improves the quality of both the steel coil and the produced box beam. Given that the steel coils used for box beam production typically have a thickness of 1.5-2 mm, the leveling machine is indispensable. Unlike conventional leveling machines consisting of 2 upper rollers and 3 lower rollers, we've configured a specialized 3-upper-roller and 4-lower-roller leveling machine to meet the specific leveling requirements for this thickness.

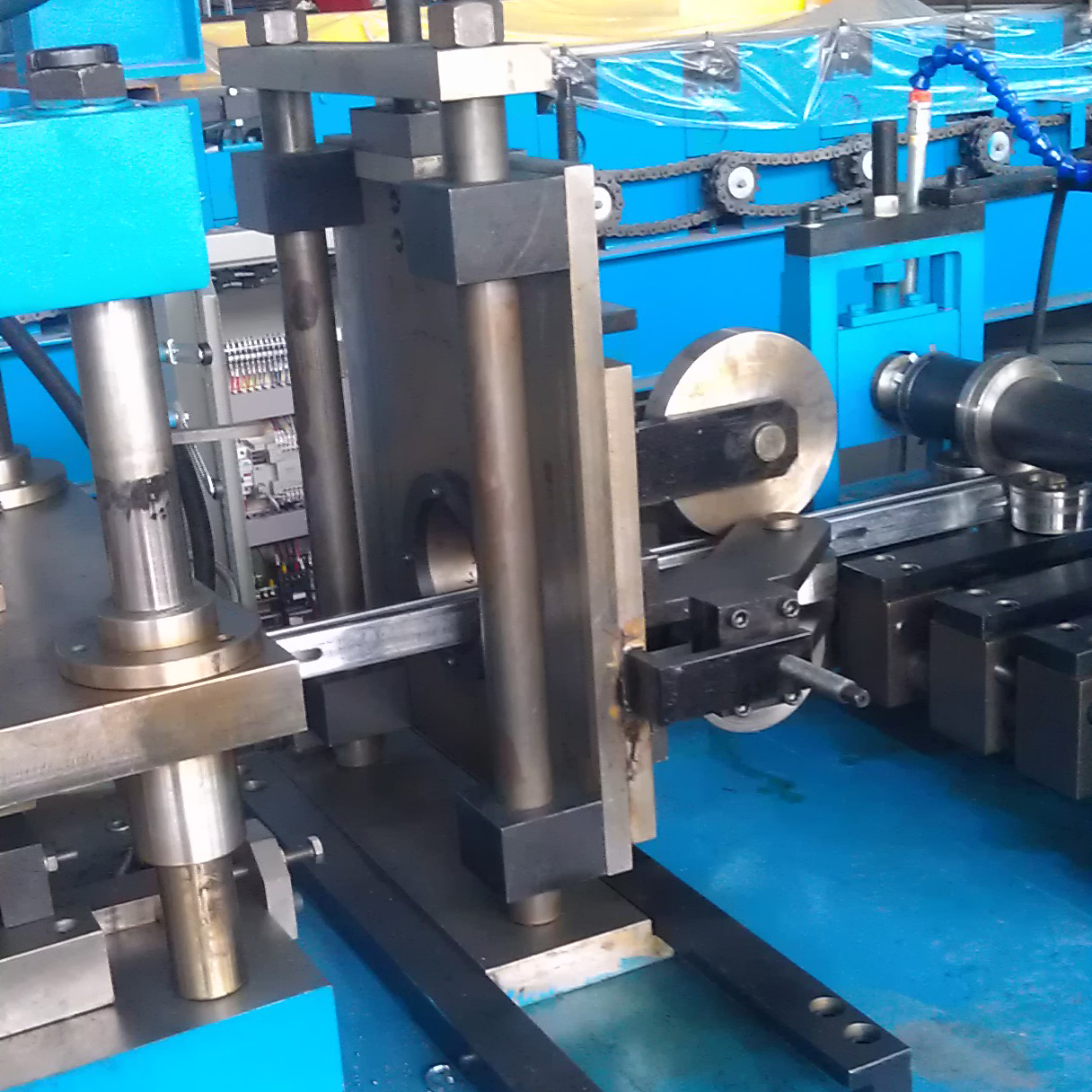

Pre-cut

Our customer who ordered this roll forming machine typically require the production of at least 13 different sizes, all of which can be accommodated by this single machine. We have configured a pre-cutting device to make it easier to replace steel coils of different widths and thicknesses, while also helping to avoid the waste of steel coils. Following this stage, the steel coil proceeds to the roll forming process.

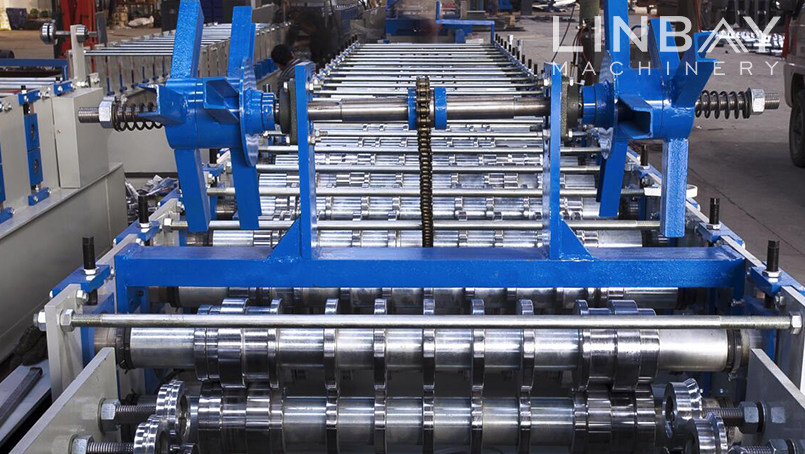

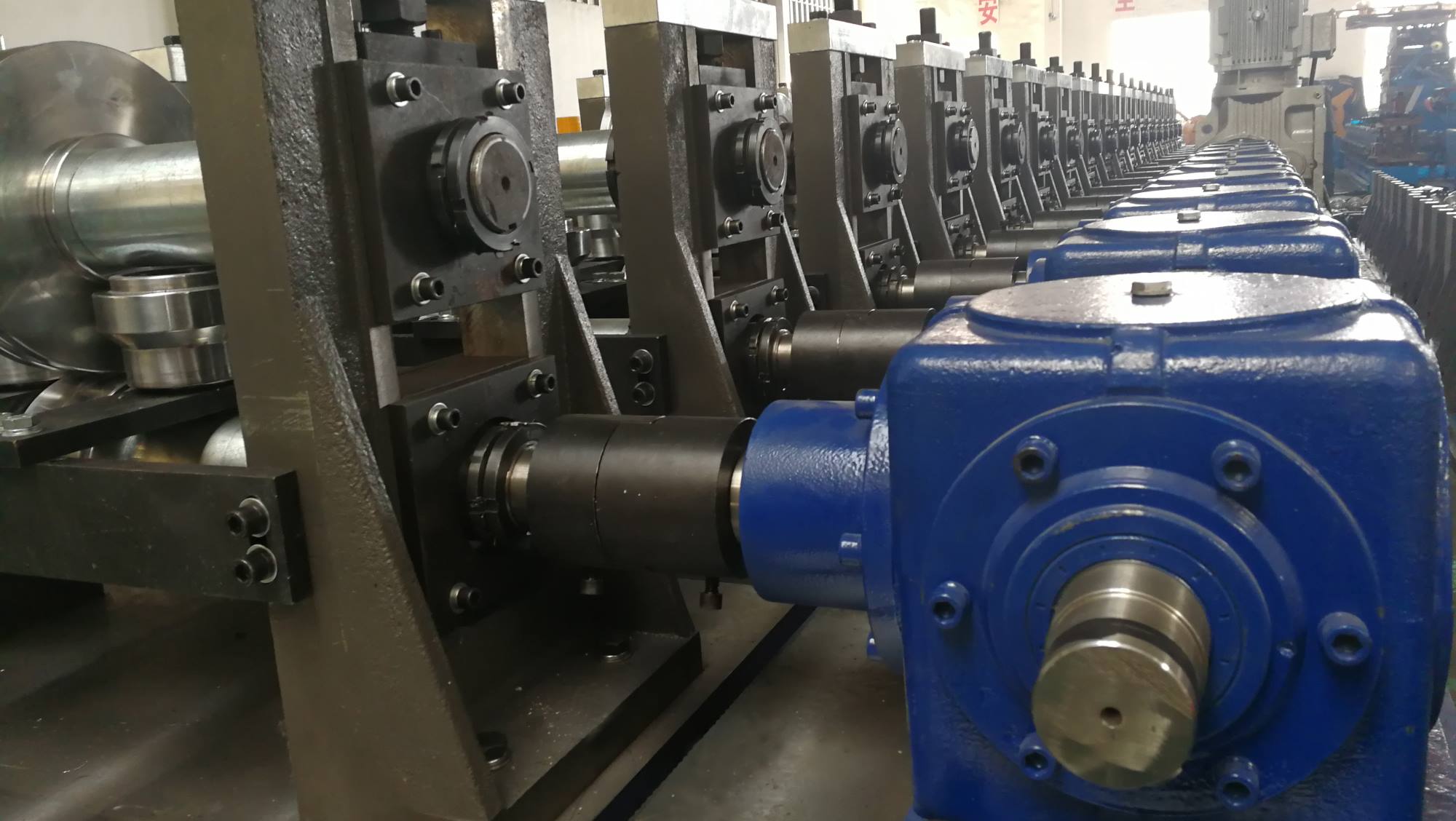

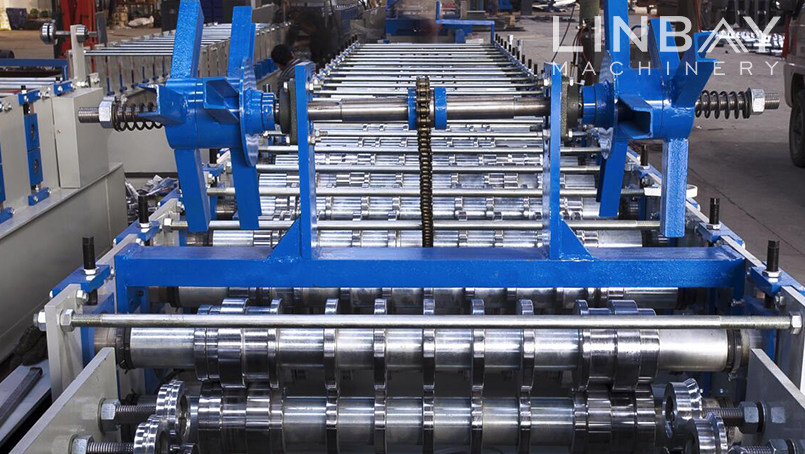

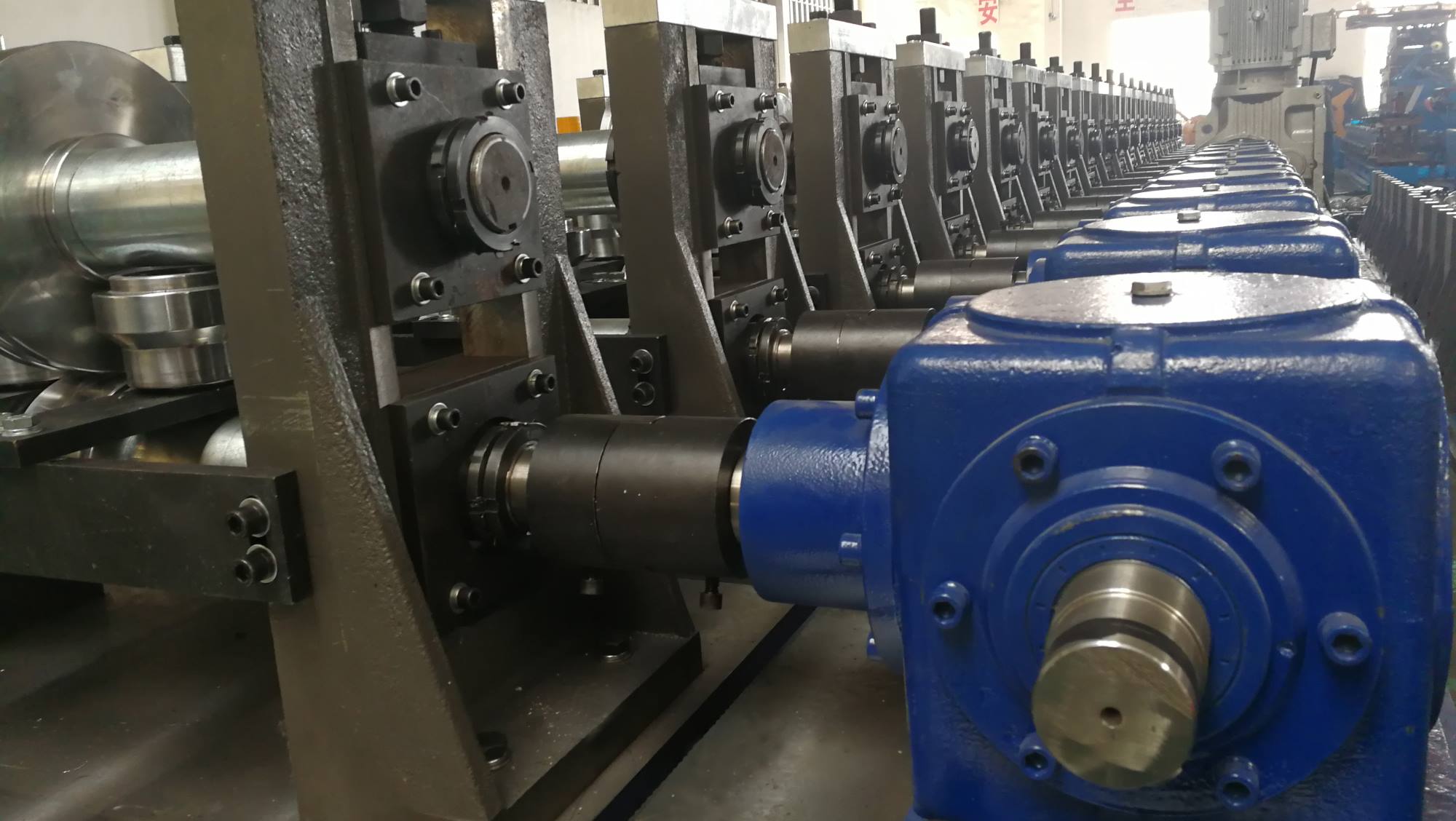

Roll former

This roll forming machine is built with a robust cast-iron structure, constructed as a single solid piece of iron, ensuring exceptional durability and stability. What sets this machine apart is its automatic size-adjustment function, enabling the production of different-sizes box beams. For instance, the forming stations can move outward on rails to reduce height or inward to increase height. Customers only need to input the desired cutting length and number via the PLC control panel, and the machine will automatically adjust, offering exceptional ease of use and efficiency.

Platform

After roll forming, profiles are transported to the turnover-platform, where one of them is automatically flipped, aligning two profiles with one on top of the other. Guiding rollers ensure precise alignment, and then the 2 profiles are fed into the seaming machine and seamlessly automated, requiring no manual intervention.

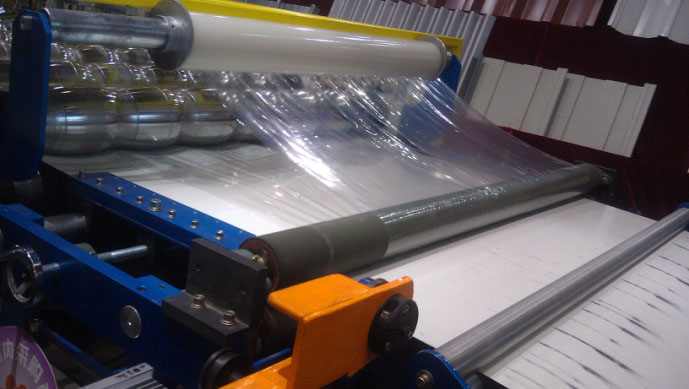

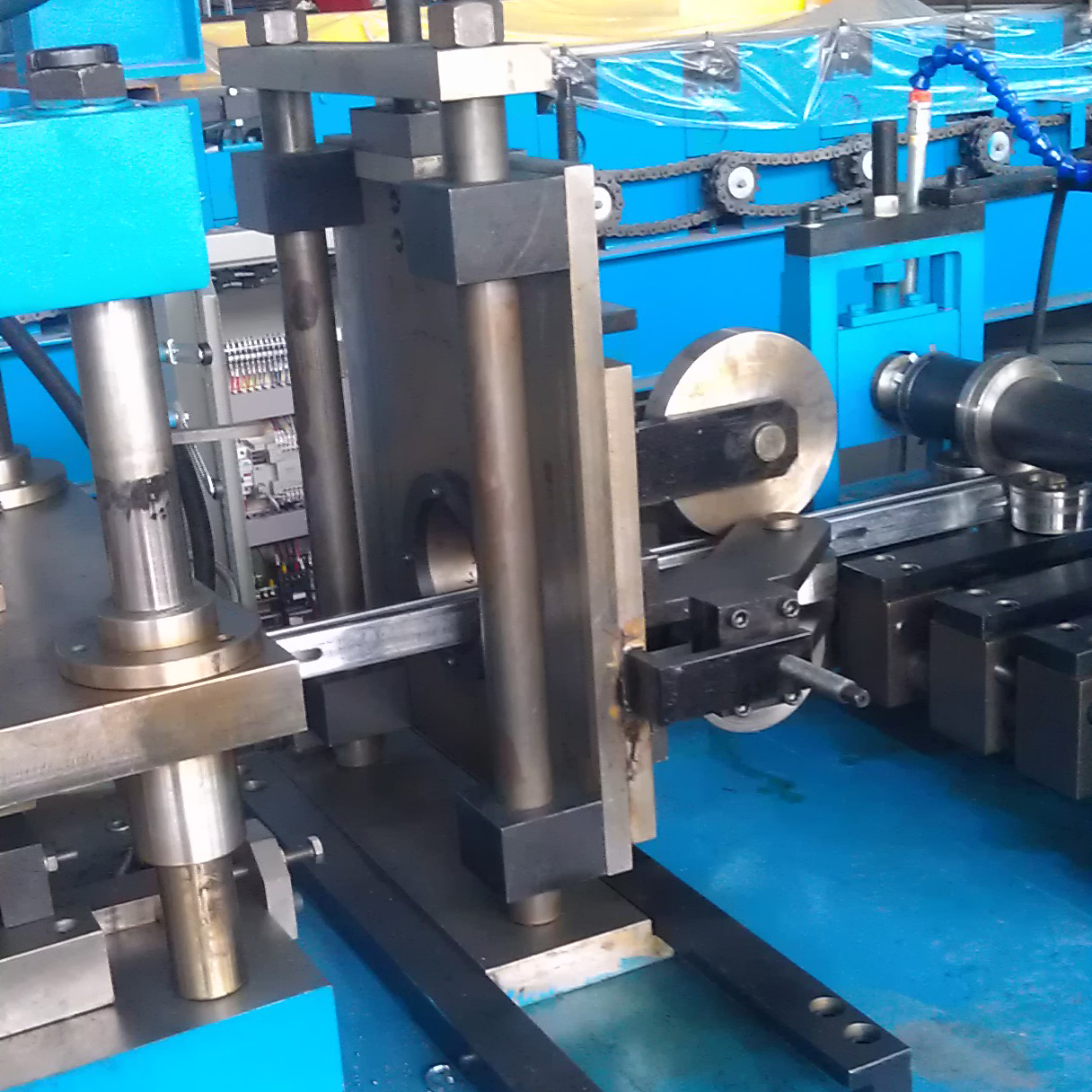

Seaming machine

The seaming machine efficiently joins two profiles securely together. The seaming rollers can also move on rails to accommodate the production of various-size box beam. Customers only need to employ one manual operator to control the PLC, eliminating the need for manual welding and the associated cost of an additional welder.

PLC+encoder

Our control panel offers multiple language options, allowing you to control production speed, production dimensions, and cutting lengths, among other parameters. Within the production line, we employ Japanese-brand encoders for precise control of cutting lengths, minimizing waste from incorrect cuts. We also provide customization services, including motor models, brands, and electronic component brands, tailored to your specific needs.

Description:

This box beam production line was installed in April, 2019 in Pakistan. It produces four sizes of interlock box beam automatically using a cantilever type structure. You could produce more sizes with this automatic change system as you wish.

|

Pallet Rack Box Beam Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):1.5-2.0 |

|

B) PPGI |

||

|

C) Cold-rolled Steel |

||

|

D) Stainless Steel |

||

|

E) Aluminum |

||

|

F) Carbon steel |

||

|

Yield strength : |

250 - 350 Mpa |

|

|

Tensil stress : |

350 Mpa-500 Mpa |

|

|

Nominal forming speed(M/MIN) |

10-20 |

* Or according to your requirement |

|

Forming station : |

18-20 |

* According to your profile drawings |

|

Decoiler : |

Manual decoiler |

* Hydraulic decoiler (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Torri stands |

* Cast iron stands (Optional) |

|

Rollers’ material : |

GCr 15 |

* SKD-11 (Optional) |

|

Cutting system : |

Hydraulic cut |

* Flying cut (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Siemens |

|

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1.Q: What kinds of experience do you have in producing pallet rack roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2.Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. One machine could produce several profiles, we would check your profile drawings to meet your needs. We are dedicated to provide cost-effective solutions.

3.Q: What is delivery time of box beam roll forming machine?

A: 80 days to 100 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Others

-

scrap collector

-

pasting

-

mould change

-

guiding head

-

-

Out table

-

Non-powered

-

auto stacker

-

-

Cutting

-

Sawing cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for C purlin

-

-

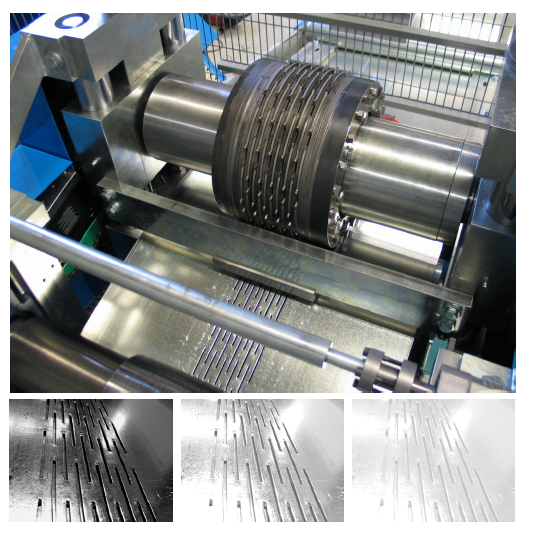

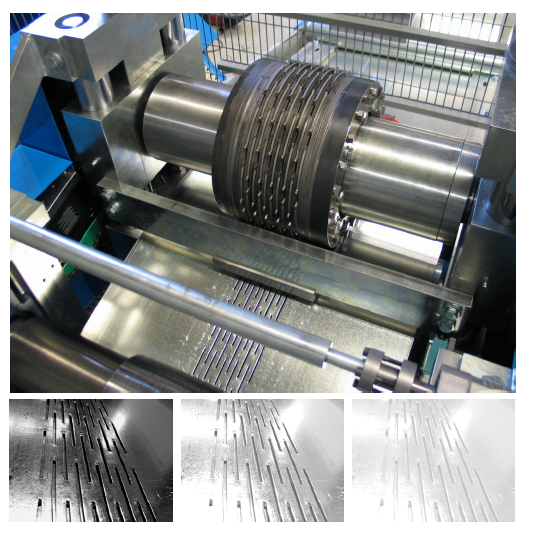

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

Manual decoiler

-

hydraulic decoiler

-

double head decoiler

-