A box beam is a robust type of racking beam designed for heavy-duty use. In this instance, we're introducing a two-piece type box beam. Typically crafted from cold-rolled steel or hot-rolled steel with a thickness 1.5 - 2mm, it undergoes roll forming and is then coated for a blend of aesthetic appeal and long-lasting durability. Two pieces of formed C-shape steel profiles are securely seamed together to create a tube structure. The cold roll forming machine is the most commonly chosen solution for producing box beam.

Flow chart

Manual decoiler--Guiding--Leveler--Hydraulic pre cut--Roll forming machine--Flying hydraulic cut--Platform--Seaming machine--Out table

Main Techinical Parameters

- Line speed: 0-4 m/min, adjustable

- Profiles: Multiple sizes-same height of 50mm, and different width of 80, 100, 120mm

- Material thickness:1.5-2mm

- Suitable material:Hot rolled steel, cold rolled steel, galvanized steel

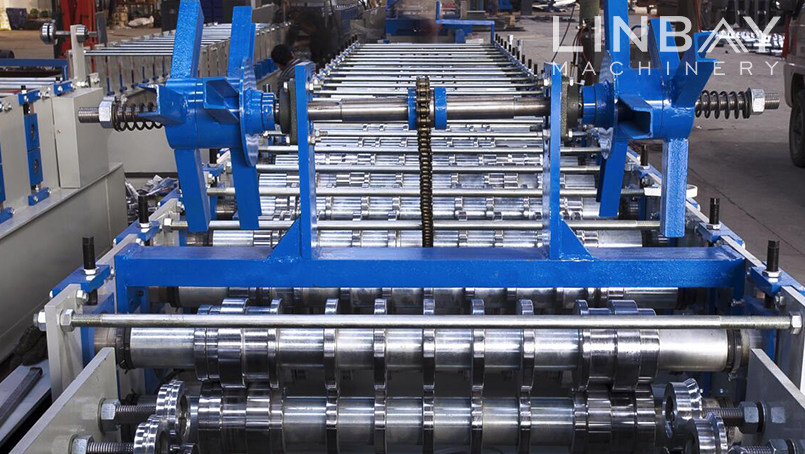

- Roll forming machine: Cast-iron structure and chain driving system.

- Of forming station: 18

- Cutting system: Hydraulic cutting, roll former doesn’t stop when cutting.

- Changing size: Automatically.

- PLC cabinet: Siemens system.

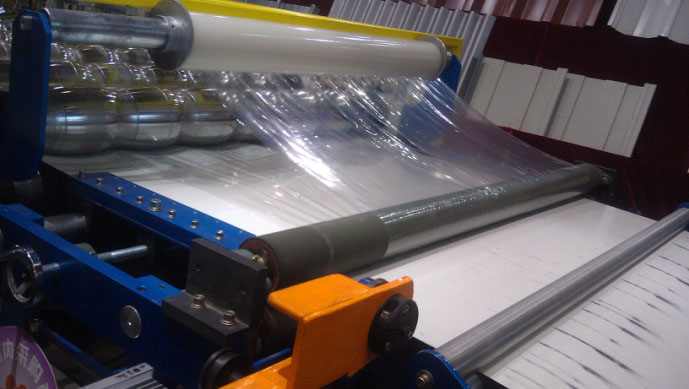

Manual Decoiler

The manual decoiler comes equipped with a braking system designed to adjust the tension of the unwinding roll and control the smoothness of the unwinding process. For steel coils exceeding a thickness of 1.5mm, the risk of sudden recoil during uncoiling is minimized by a press arm securing the steel coil. Additionally, steel protection leaves are installed to prevent coil slippage during the uncoiling phase. This thoughtful design ensures not only high cost-effectiveness but also enhances safety.

In this scenario, a manual decoiler without its own power source is employed. For more substantial production speed requirements, we offer an optional hydraulic decoiler powered by a hydraulic station.

Guiding

Guiding rollers play a crucial role in maintaining alignment between the steel coil and the machine, preventing distortion of the box beam. They also contribute to the forming process by preventing rebound deformation of the steel coil. The straightness of the box beam significantly impacts product quality and the load-bearing performance of the entire shelf. Guiding rollers are strategically positioned along the entire forming line, ensuring precise positioning. Measurements of each guiding roller to the edge are meticulously recorded in the manual, facilitating easy adjustments based on this data even if slight displacements occur during transportation or production.

Leveler

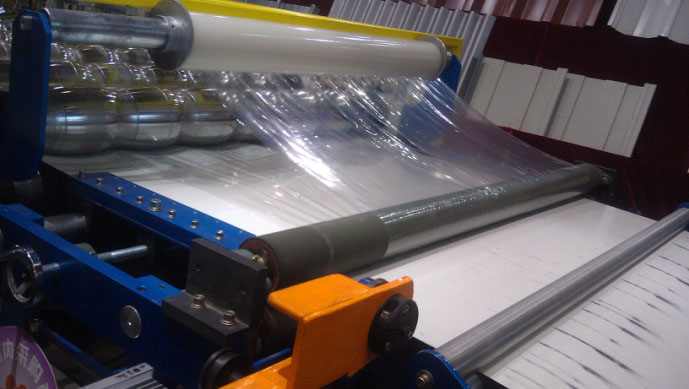

Subsequent to this stage, the steel coil undergoes the leveling process. The leveling machine effectively removes the curvature of the steel coil, enhancing its flatness and parallelism to elevate the overall quality of the final product-box beam. The leveling machine is outfitted with 2 upper and 3 lower leveling rolls.

Hydraulic Pre-Cut

This production line incorporates a hydraulic pre-cutting device, simplifying the replacement of steel coils with varying widths and thicknesses, while simultaneously minimizing coil waste.

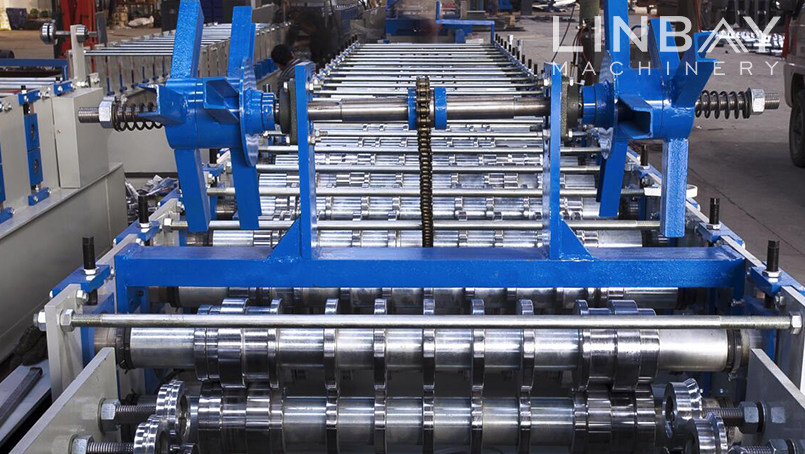

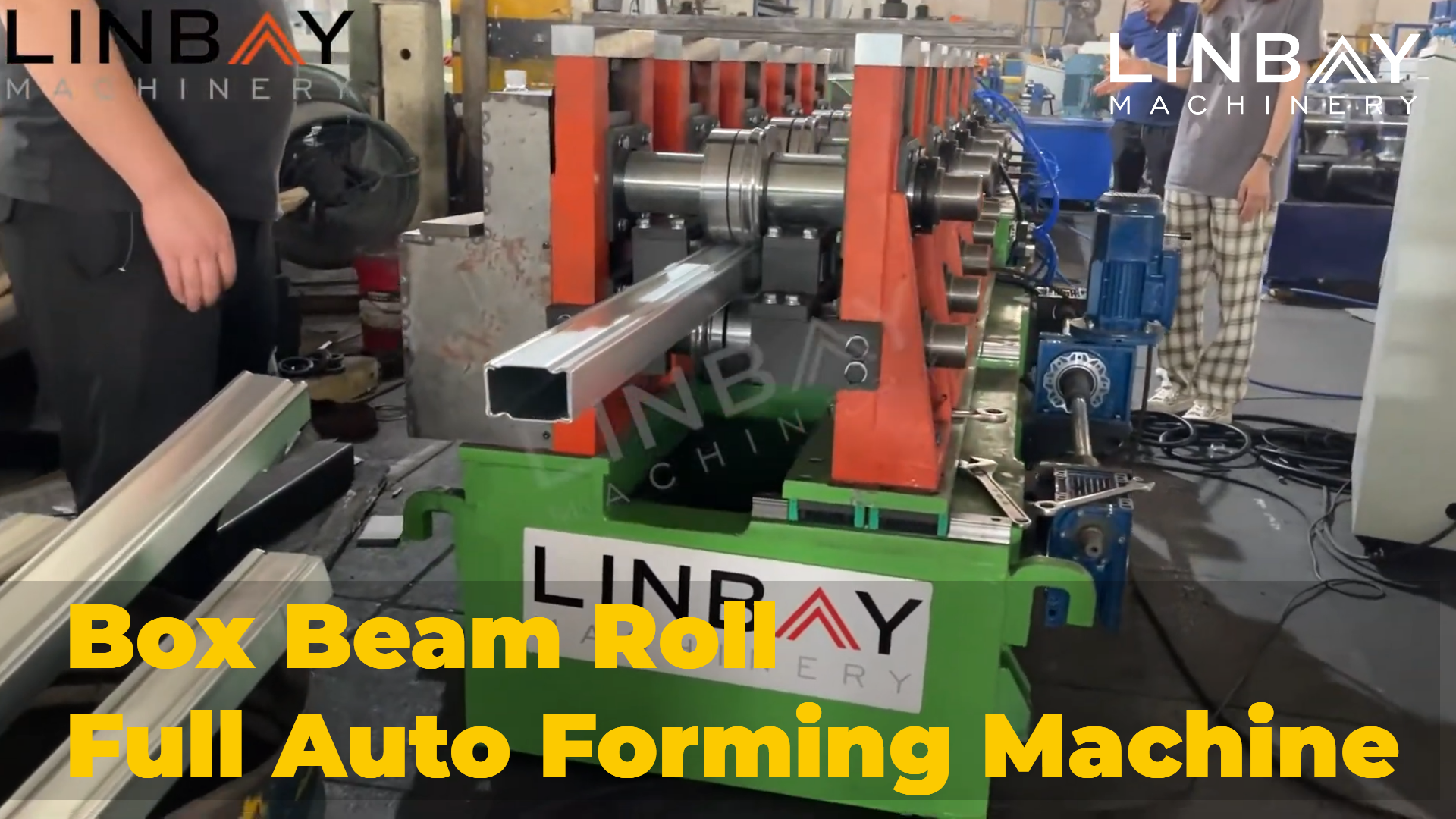

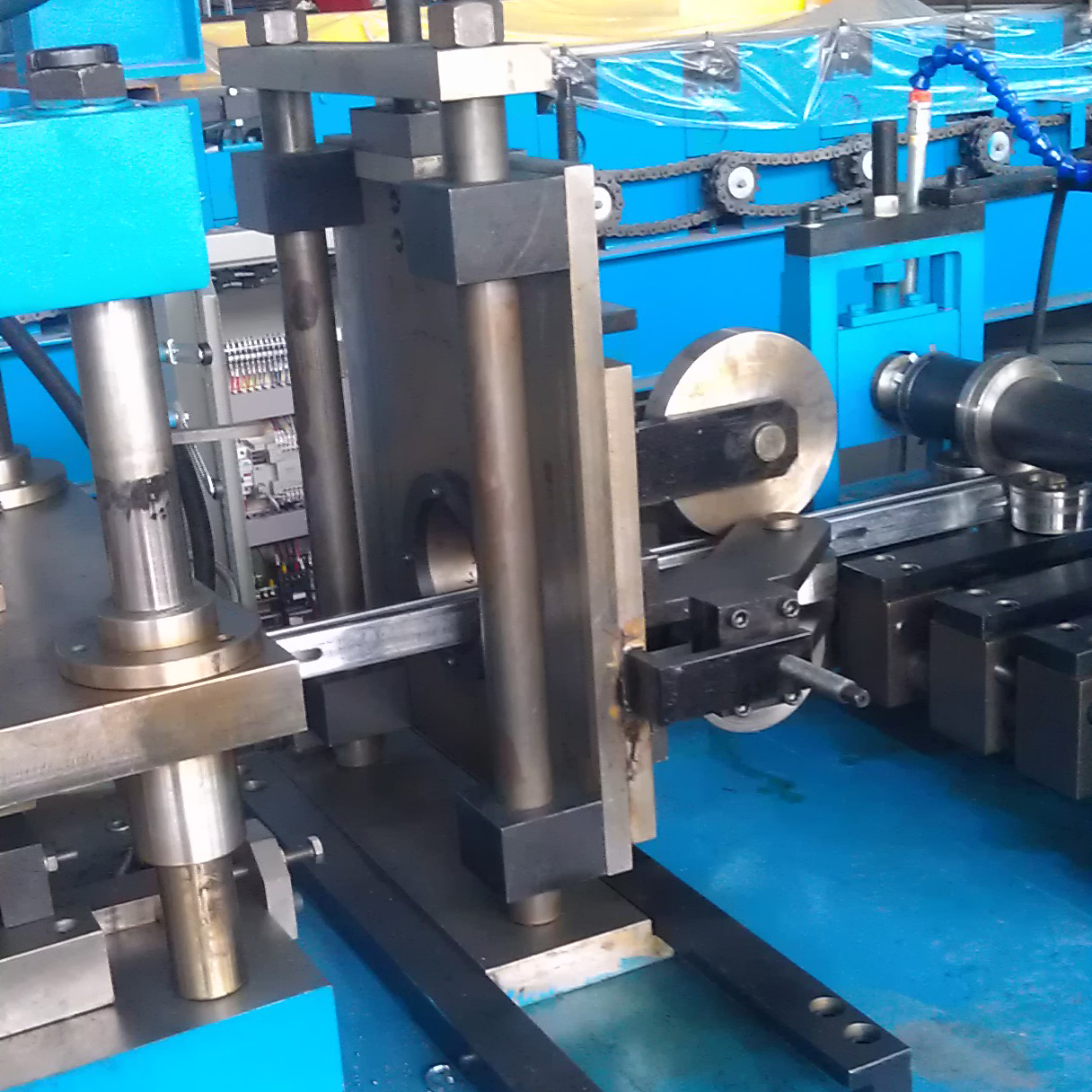

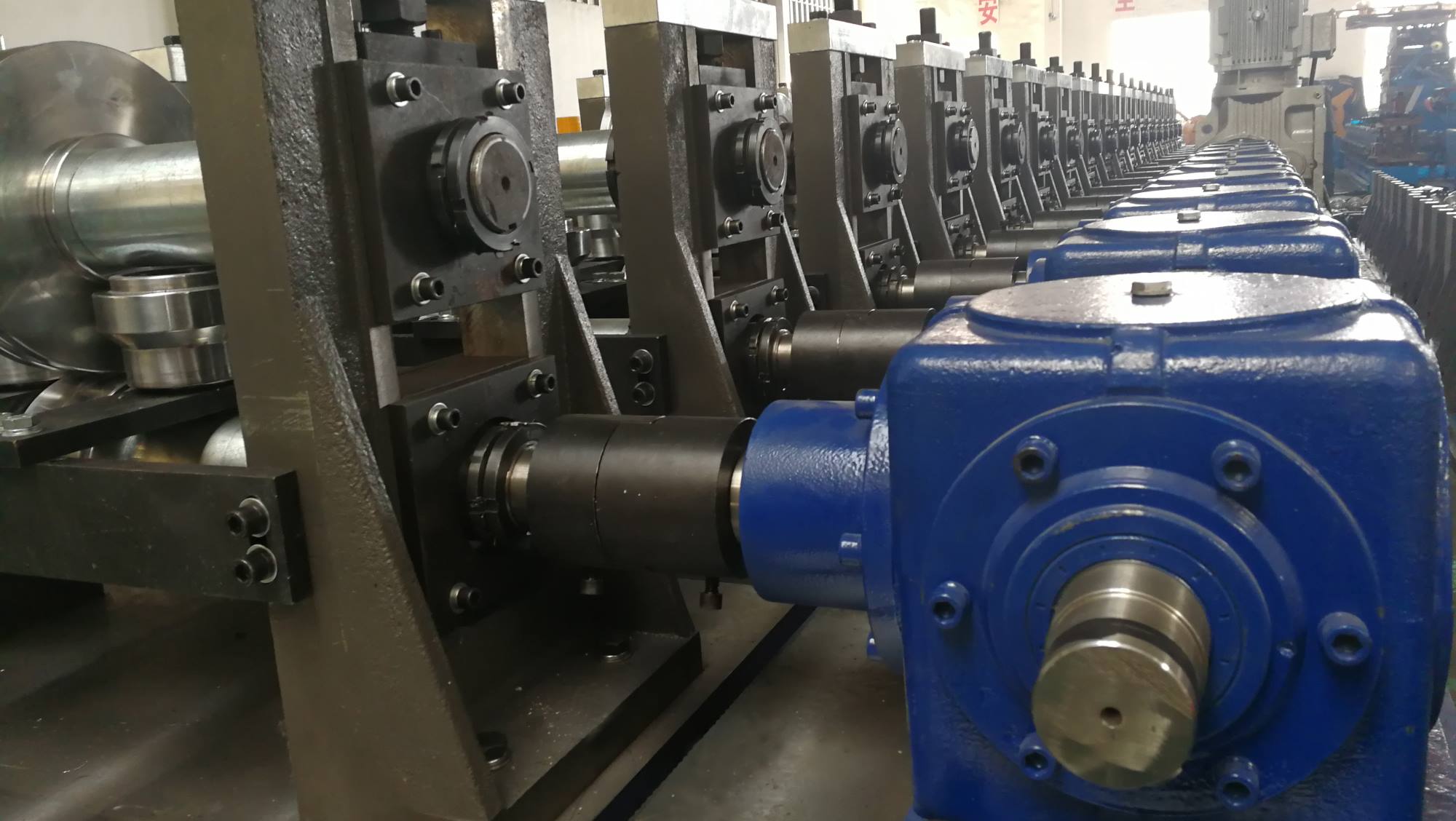

Roll Forming Machine

The roll forming machine stands as the pivotal component of the entire production line. This machine employs cast-iron structure made from whole piece solid steel and is driven by chain system. It has the capability to produce various sizes with uniform height. Workers input planned sizes on the PLC control screen, enabling automatic adjustment of forming stations to precise positions. Experienced workers typically take around 60 minutes to complete the entire process of changing dimensions, including the automatic movement of the forming stations and the manual replacement of the steel coil.

The A point serves as a crucial forming point for alterations in width. The movement of roll forming stations on the rails shifts this key forming point's position, facilitating the production of box beams with different widths.

Gcr15, a high-carbon chromium-bearing steel recognized for its hardness and wear resistance, is utilized for the material of forming rollers. The rollers undergo chrome-plating for prolonged durability. The shafts, made of 40Cr material, undergo heat treatment.

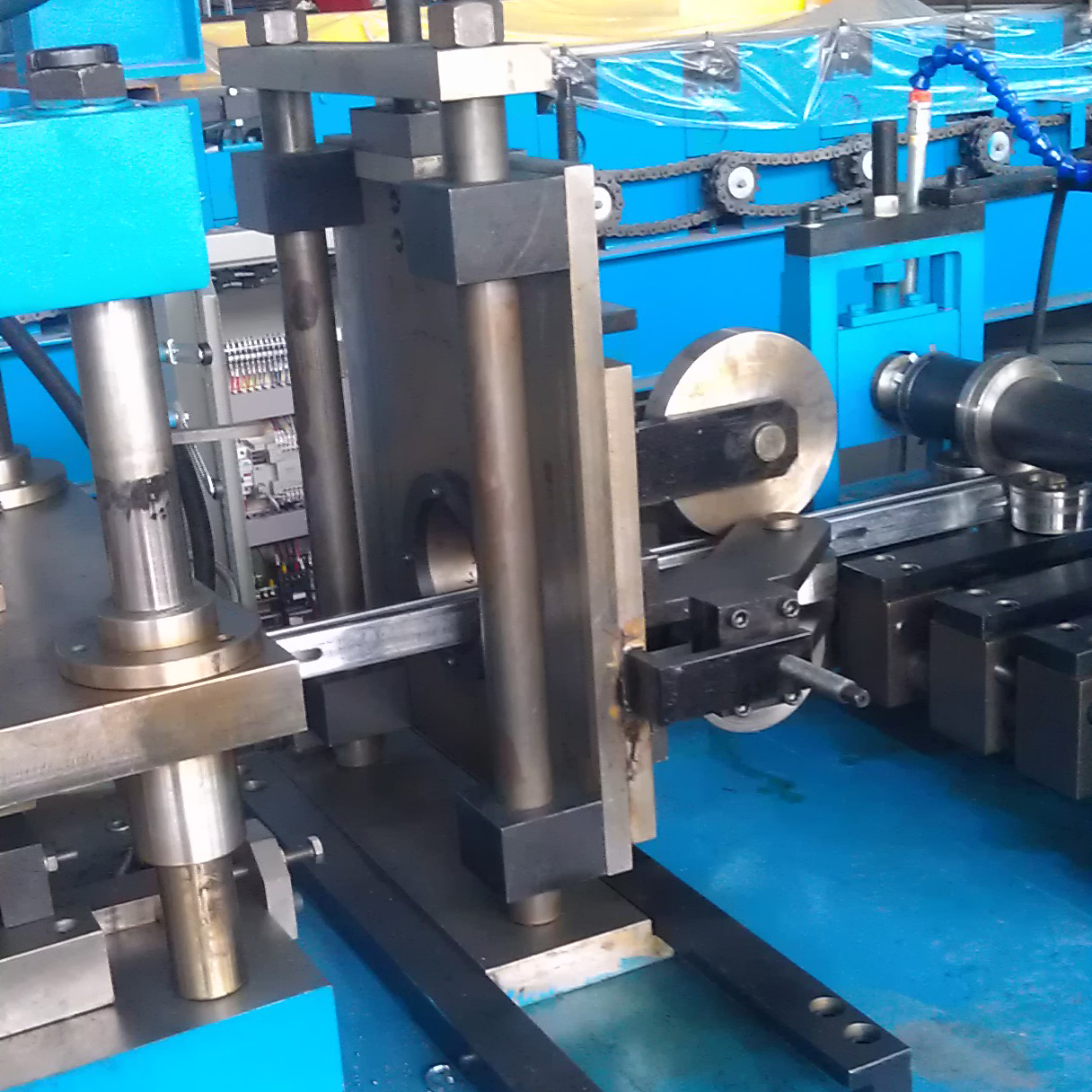

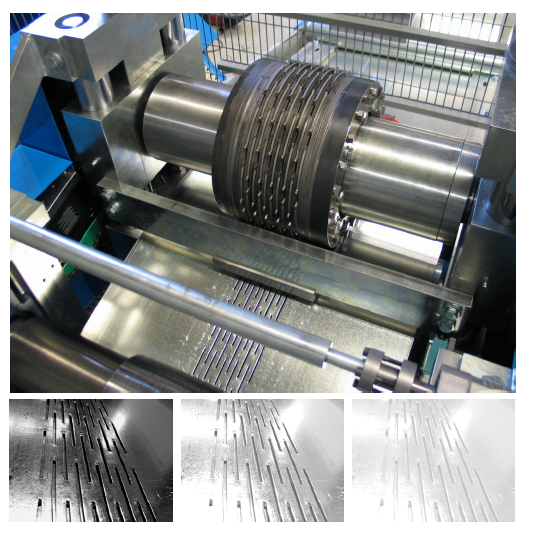

Flying Hydraulic Cut

Following the passage through the roll forming machine, the steel coil progressively takes on force to adopt a C-shaped profile, subsequently being cut to the specified length by a hydraulic cutting machine. And the cutting length error is kept within 1mm. This cutting machine minimizes steel coil wastage and can keep pace with the production speed of the roll forming machine, ensuring uninterrupted operation.

Platform

The first formed C-profile is initially transferred to the end of the upper platform and then pushed onto the lower platform. The second C-profile undergoes a controlled push onto the middle slope, where a flipping device rotates it, aligning and neatly stacking the two C-profiles vertically.

Guiding rollers ensure alignment of the two C-profiles, and pneumatic push rods push them into the seaming machine.

Seaming machine

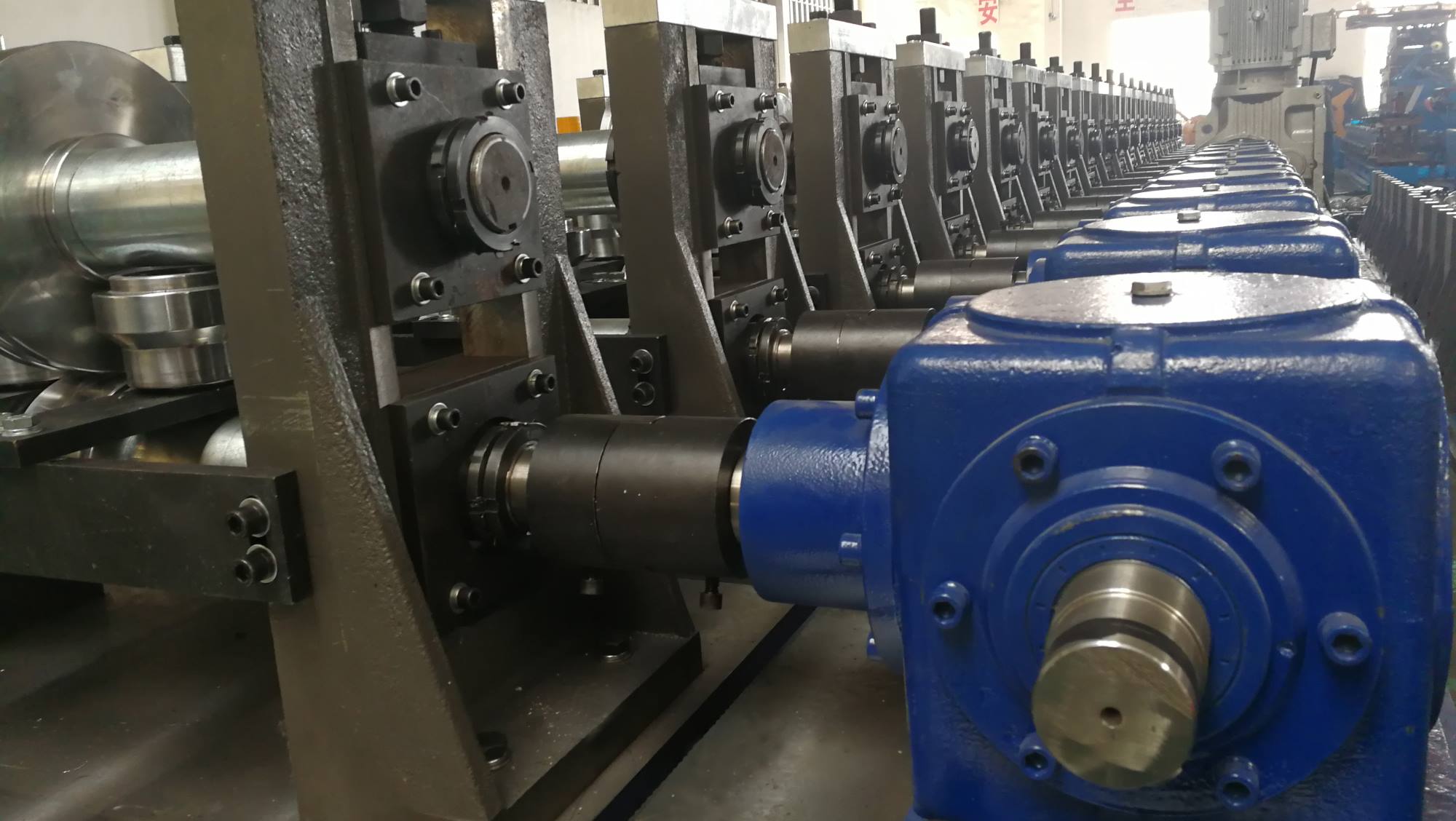

The seaming machine is designed with the same structure as the roll forming machine, featuring a cast-iron structure and chain driving system. It can automatically adjust the position of the seaming stations based on the width of the box beam. This machine saves the cost of a welder, as in traditional methods, a worker is hired to weld the two C-profiles into a box beam after roll forming. Subsequently, only labor is required for handling the finished product.

Encoder & PLC

The roll forming machine incorporates a Japanese Koyo encoder that translates sensed coil lengths into electrical signals transmitted to the PLC control cabinet. This precision ensures that cutting errors are kept within 1mm, ensuring the production of high-quality box beams and minimizing waste from incorrect cuts. Operators can manage production speed, set production dimensions, cutting length, and more through the PLC screen. The PLC control cabinet features memory storage for commonly used parameters and protection functions such as overload, short circuit, and phase loss. The language displayed on the PLC screen is customizable to cater to customer requirements.

Hydraulic Station

Our hydraulic station, equipped with cooling electric fans, efficiently dissipates heat, ensuring extended and reliable operation with a low failure rate.

Warranty

Upon shipment, the nameplate clearly indicates the delivery date, providing a two-year guarantee for the entire production line and an impressive five-year warranty for rollers and shafts.

Single Roll-Formed box beam VS Double C-Shape box beam

- Load-bearing capacity: The single roll-formedbeam is less than the double C-Shapebeam in terms of load-bearing capacity. This is because the single roll-formed beam has only two layers of overlap on the upper width, while the double C-Shape beam has two layers of overlap on both upper and lower widths.

- Production Speed: The single roll-formedbeam operates at a speed of 5-6m/min, while the double C-Shapebeam operates at 0-4m/min.

- Raw Material Usage: For the same dimensions, the double C-Shapebeam requires more material than the single roll-formedbeam, equivalent to the additional material in the area of bottom width multiplied by length.

- Cutting Machine: The single roll-formedbeam utilizes saw cutting, suitable for cutting beams of various sizes. The double C-Shapebeam employs hydraulic diagonal cutting, requiring a specific blade for each size.

- Production Line Layout: For reference only. The length of the single roll-formedbeam production line is 26050mm, while the double C-Shapebeam production line is 33367mm. The single roll-formed beam production line has simpler processes: uncoiling, forming, cutting, and discharge. The double C-Shape beam production line involves additional steps: uncoiling, forming, cutting, transport platform, interlocking, and discharge. However, both lines only require one worker for supervision, with the main difference being the significant disparity in length.

- Price: For the same multi-size automatic transverse movement solution, the production cost of the double C-Shapebeam line is slightly lower than that of the single roll-formedbeam line.

|

Pallet Rack Box Beam Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):1.5-2.0 |

|

B) PPGI |

||

|

C) Cold-rolled Steel |

||

|

D) Stainless Steel |

||

|

E) Aluminum |

||

|

F) Carbon steel |

||

|

Yield strength : |

250 - 350 Mpa |

|

|

Tensil stress : |

350 Mpa-500 Mpa |

|

|

Nominal forming speed(M/MIN) |

10-20 |

* Or according to your requirement |

|

Forming station : |

18-20 |

* According to your profile drawings |

|

Decoiler : |

Manual decoiler |

* Hydraulic decoiler (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Torri stands |

* Cast iron stands (Optional) |

|

Rollers’ material : |

GCr 15 |

* SKD-11 (Optional) |

|

Cutting system : |

Hydraulic cut |

* Flying cut (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Siemens |

|

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1.Q: What kinds of experience do you have in producing pallet rack roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2.Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. One machine could produce several profiles, we would check your profile drawings to meet your needs. We are dedicated to provide cost-effective solutions.

3.Q: What is delivery time of box beam roll forming machine?

A: 80 days to 100 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Others

-

scrap collector

-

pasting

-

mould change

-

guiding head

-

-

Out table

-

Non-powered

-

auto stacker

-

-

Cutting

-

Sawing cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for C purlin

-

-

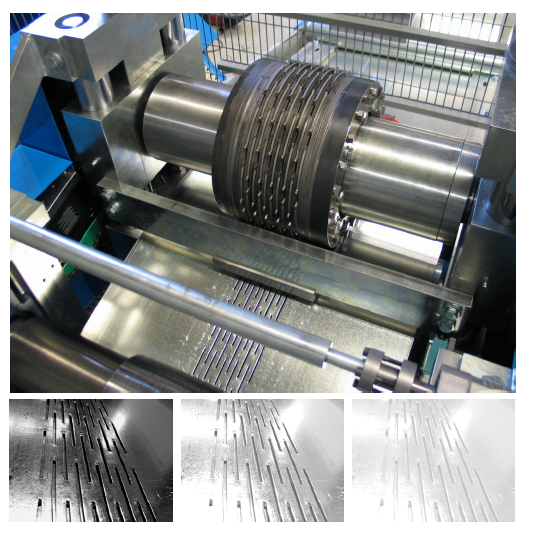

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

Manual decoiler

-

hydraulic decoiler

-

double head decoiler

-