Romania Trapezoidal Panel TR12_828 Roll Forming Machine

This is a standard trapezoidal panel commonly used in Romania for roofing and cladding applications. It finds applications in industrial and construction projects, small warehouses and sheds, as well as coverings for agricultural and animal husbandry facilities.

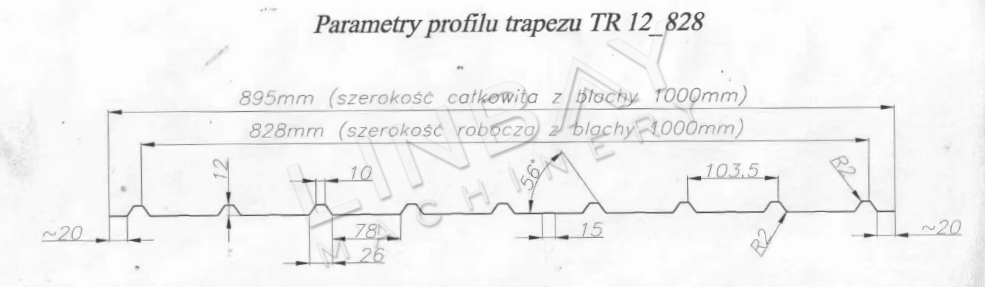

Typically manufactured through cold roll forming process, this trapezoidal panel has an overall width of 895mm, a cover width of 828mm, a wave height of 12mm, an upper wave width of 10mm, a lower wave width of 26mm, and a wave pitch of 78mm. It is available in thicknesses ranging from 0.3mm to 0.6mm, and can be produced using galvanized steel, aluminum steel, or color-coated steel coils. Among these materials, the most commonly used for trapezoidal panel is galvalume steel, which provides anti-rust effects better than galvanized steel.

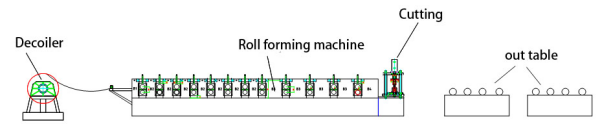

Flow chart

Decoiler--Roll former--Hydraulic cut--Out table

7.5 Ton Hydraulic Decoiler

In this production line, we use a hydraulic decoiler with a load capacity of 7.5 tons. Producing trapezoidal panels requires wide steel coils, and the process of changing coils poses potential safety risks for workers. Additionally, protective iron leaves on the outer side of the coil prevent slipping during the decoiling process, with these design features prioritizing worker safety.

An optional device: a loading car, assisting in transporting coils to the decoiler, saving time, and enhancing worker safety, especially in facilities without overhead cranes.

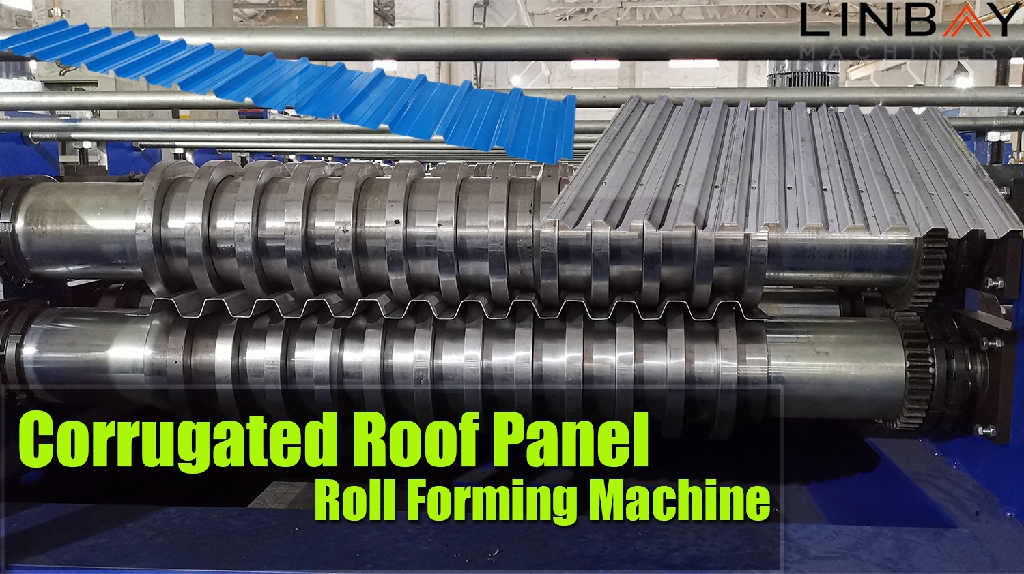

Roll Forming Machine

The roll forming machine is the most crucial part of this production line, featuring a total of 20 forming stations. It adopts a wall panel structure and chain driving system. The forming rollers are made of Gcr15, a high-carbon chromium-bearing steel known for its excellent hardness and wear resistance. Chrome plating on the roller surface extends the roller's lifespan, while the shafts are made of heat-treated 40Cr material.

Protective covers on the chain prevent dust buildup or fragments damaging the chains, also ensuring worker safety. The roll forming machine is tested using steel coils with the same yield strength as those used in customer production, providing convenience for production upon delivery.

Hydraulic Cut & Encoder

The roll forming machine incorporates a Koyo encoder from Japan, converting sensed steel coil length into electrical signals transmitted to the PLC control cabinet. This allows the cuttiing machine to control cutting errors within 1mm, ensuring high product quality and minimizing waste from incorrect cuts. The hydraulic cutting machine obtains powerful cutting force from the hydraulic station. The cutting process produces no waste, and the cut edges are smooth without burrs. We will test the roll forming machine until it can produce the profile matches the drawing. And then we will produced the matched blade molds based on the sample. Although this approach may slightly increase both time and labor costs, the cutting machine produced in this manner exhibits exceptionally smooth edges without any burrs.

Hydraulic Station

Our hydraulic station is equipped with cooling electric fans, aiding efficient heat dissipation for continuous and cool operation, contributing to increased work efficiency. The hydraulic station boasts a low failure rate and long-term durability.

PLC control cabinet

Workers can control production speed, set production dimensions, cutting lengths, etc., through the PLC screen. The PLC control cabinet includes protective functions such as overload, short circuit, and phase loss protection. The language of the PLC screen can be customized in a certain language or multiple languages according to customer needs.

Regular Out Table & Optional: Auto Stacker

.jpeg)

For the transporting productions, a regular out table is available, non-powered, customizable in length and width according to customer needs.

However, when the length of the trapezoidal panel exceeds 6m, considering the width and weight of the panel, we recommend using an auto stacker to reduce manual labor costs and enhance overall efficiency and work safety. After cutting, the trapezoidal panels are conveyed to the stacker's swing arm, gently layering the panels. And then, the panels are transported outward along the conveyor.

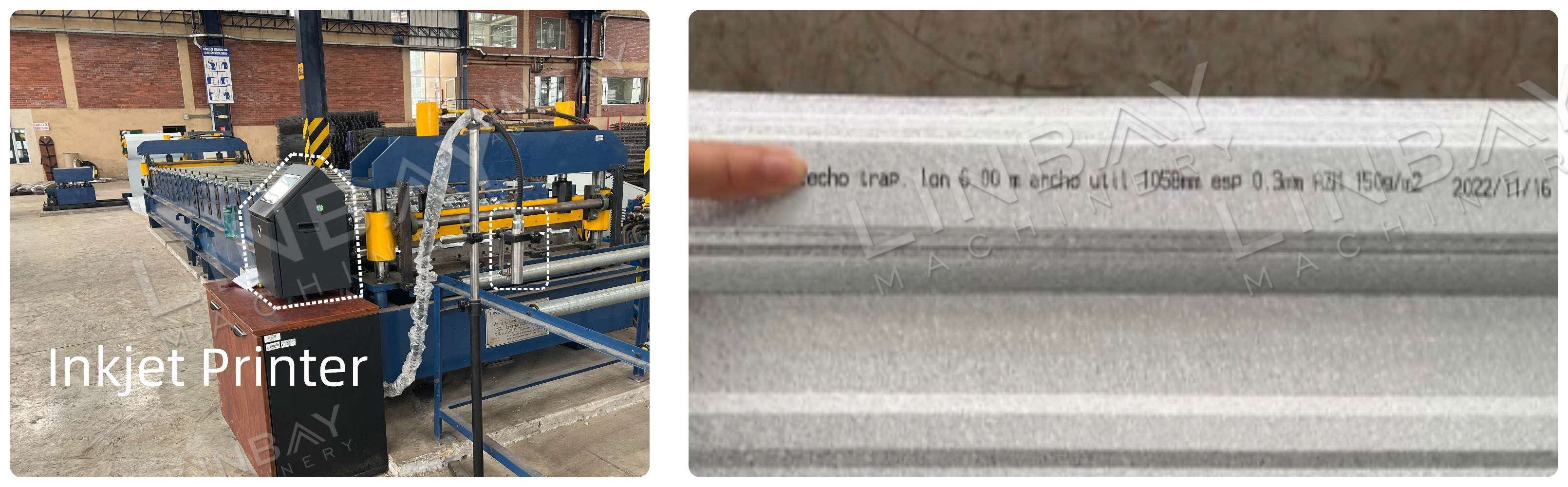

Other optional: Ink printer

Customers can use the ink printer to print company name, logo, profile number, and other information on the panel surface. It can help companies quickly expand their markets and increase their visibility. The ink dries quickly and will not contaminate the surface.

Warranty

Before delivery, the delivery date is indicated on the nameplate, starting a two-year guarantee for the entire production line and a five-year warranty for rollers and shafts.

Decoiler--Roll former--Roller 2--Hydraulci cut --Wastage collector--Out Table

|

Trapezoidal Roof Panel Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):0.3-0.8 |

|

B) PPGI |

||

|

C) Aluminum Coil |

||

|

Yield strength : |

200 - 350 Mpa |

|

|

Tensil stress : |

200 Mpa-350 Mpa |

|

|

Nominal forming speed(M/MIN) |

0-20 |

* Or according to your requirement (Optional) |

|

Forming station : |

18 stands |

* According to your profile drawings (Optional) |

|

Decoiler : |

Manual decoiler |

* Hydraulic decoiler (Optional) |

|

Punching system |

No |

* Hydraulic punching (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Wall panel station |

* Forged Iron station or torri stand structure (Optional) |

|

Rollers’ material : |

Steel #45 |

* GCr 15 (Optional) |

|

Cutting system : |

Post-cutting |

* Pre-cutting (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Panasonic |

* Siemens (optional) |

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1.Q: What kinds of experience do you have in producing roof panel roll forming machine?

A: Roof/wall panel (corrugated panel) roll forming machine is the most produced machine, we have many experience of this machine. We have exported to India, Spain, UK, Mexico, Peru, Argentina, Chile, Bolivia, Dubai, Egypt, Brazil, Poland, Russia, Ukraine, Kazakhstan, Bangladesh, Bulgaria, Malaysia, Turkey, Oman, Macedonia, Cyprus, USA, South Africa, Cameroon, Ghana, Nigeria etc.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, furring channel roll forming machine, ceiling T bar roll forming machine, wall angle roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

2.Q: How many profiles can produce this machine?

A: According to your drawing, specially the height and pitch of each wave, if they are the same, you could produce several sizes with different feeding coil width. If you want to produce one trapezoidal panel and one corrugated panel or a roof tile, we would recommend you a double layer roll forming machine to save your space and cost of machine.

3.Q: What is delivery time of corrugated roof panel roll forming machine?

A: 45 days to design from beginning to lubricate all rollers before shipment.

4.Q: What is your machine speed?

A: Our forming speed is 0-20m/min adjustable by Yaskawa frequency changer.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-