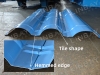

The ridge cap covers the joint between the two slopes, sealing off the area from rain and dust. They come in various shapes to match different types of metal roofing panel,made from the 0.3-0.6mm color coated steel, PPGI and galvanized steel.

Real case-Flow chart

Decoiler--Guiding--Roll forming machine--Hydraulic punch--Hydraulic cut--Out table

1.Line speed: 0-10m/min, adjustable

2.Suitable material: Color coated steel, galvanized steel and PPGI

3.Material thickness: 0.3-0.6mm

4.Roll forming machine: Wall-panel structure

5.Driving system: Chain system

6.Cutting system:Hydraulic cutting, the roll former stops when cutting.

7.PLC cabinet: Siemens system.

1.Manual decoiler*1(We also offer electrical and hydraulic decoiler, know more in DESCRIPTION below)

2.Roll forming machine*1

3.Hydraulic punch machine*1

4.Hydraulic cutting machine*1

5.Out table*2

6.PLC control cabinet*1

7.Hydraulic station*1

8.Spare parts box(Free)*1

Decoiler

The decoiler comes in manual (non-powered), electric, and hydraulic models, chosen based on the thickness, width, and weight of the steel coil. A manual decoiler is sufficient to stably support the 0.6mm thick coil and ensure smooth uncoiling.

The central shaft of the uncoiler is used to place the steel coil, also called core expansion device, capable of expanding and contracting to fit coil inner diameters between 460-520mm, ensuring safe and smooth uncoiling. We also equip it with an outward coil retainer to prevent the coil from slipping off, ensuring worker safety.

Guiding

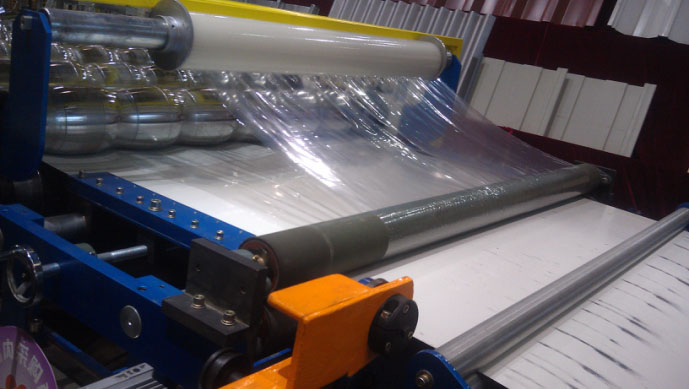

Guide rollers assist the steel coil in entering the roll forming machine and ensure the coil aligns with the same centerline of other machines. This guarantees the straightness of the ridge cap and the accuracy of the forming pressure points.

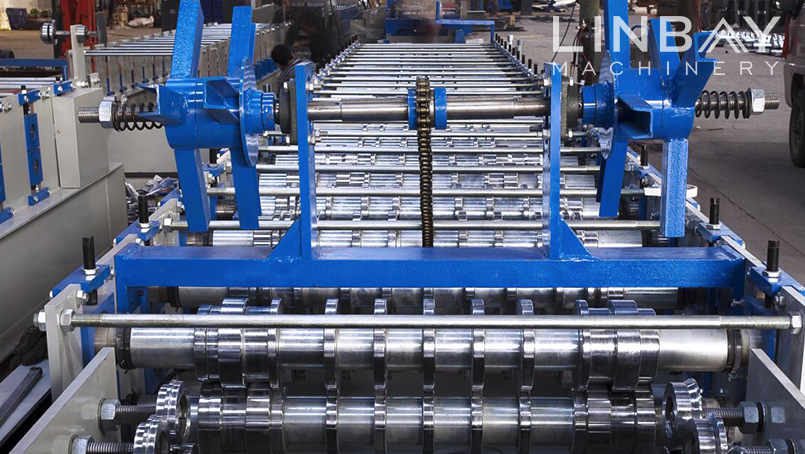

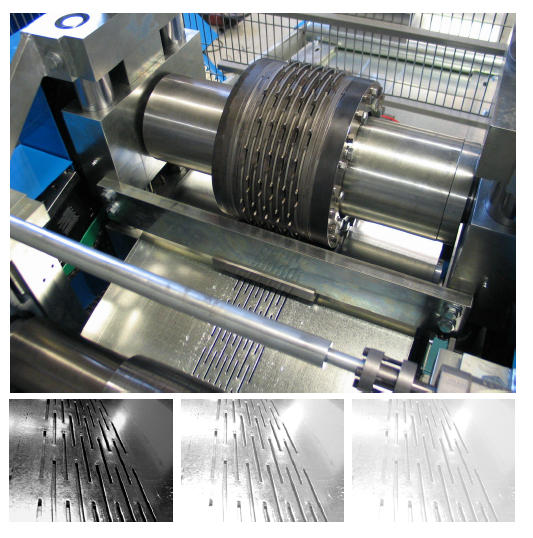

Roll forming machine

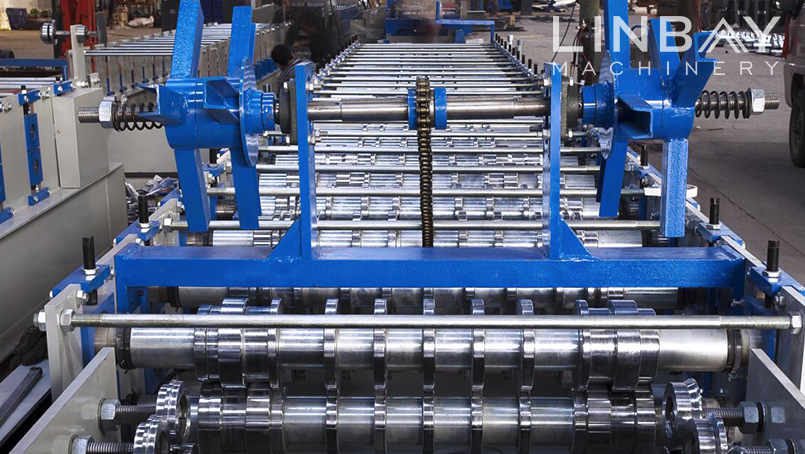

The wall panel structure and chain driving system can effectively form thin sheets with thicknesses of 0.3-0.6mm, making it a cost-effective choice. The chain is covered by an iron casing, which protects both the workers from hurt and the chains from debris damage. Under the action of the forming rollers, the steel coil undergoes pressure and tensile forces, achieving the desired shape.

There are 16 forming stations in total, each accurately designed according to the client's drawings, considering wave height, arc radius, and straight edges on ridge cap’s both sides, without scratching the coil surface or the paint coating.

This ridge cap features hemmed edges to reduce sharpness and protect workers from getting hurt. Additionally, the hemmed design conceals the edge of the metal to prevent edge creep, minimizing rust formation at the ridge cap edge.

Stamping

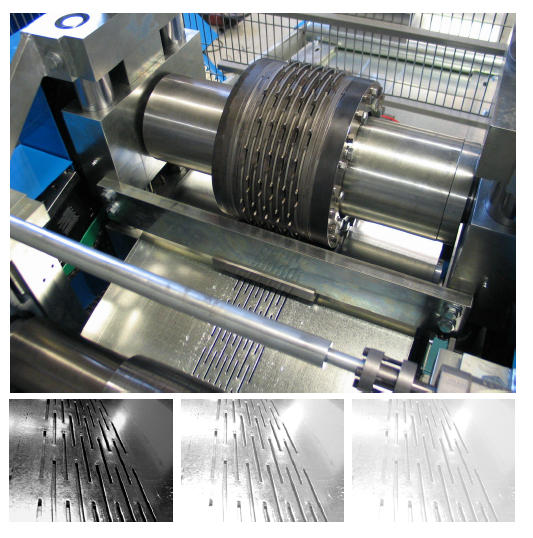

After forming, the steel coil has a semi-circular shape. Then, we use a hydraulic punch machine to stamp the tile's raised shape. This is done both for profiling and to increase the ridge cap's longitudinal strength. The stamping interval can be set on the PLC screen. The stamping mold can be customized according to your drawings.

Encoder, PLC Control Cabinet, & Hydraulic cutting

The encoder precisely detects the length of the advancing steel coil and converts it into an electrical signal, which is transmitted to the PLC control cabinet. Workers can set production speed, batch quantity, and cutting length on the PLC cabinet screen. With accurate feedback from the encoder, the hydraulic cutting machine can control the cutting length error within ±1mm.

The cutting blades are precisely customized according to the drawings, ensuring the cutting edges are not deformed and have no burrs.

-

Others

-

Scrap Collector

-

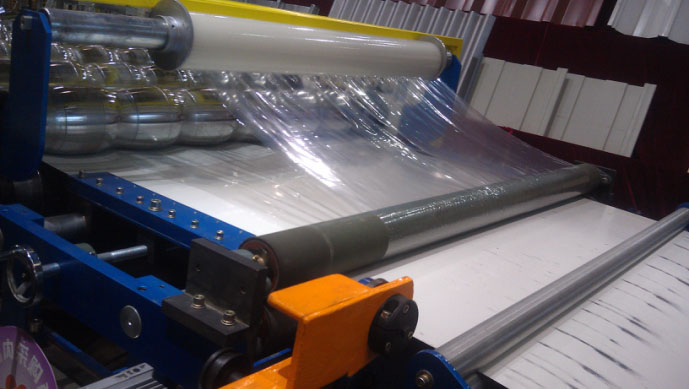

Pasting

-

Mould Change

-

Guiding Head

-

Cooling System

-

-

Out table

-

Non-Powered

-

Auto Stacker

-

-

Cutting

-

Fixed Saw Cutting

-

Flying Shear

-

Universe Cutting

-

-

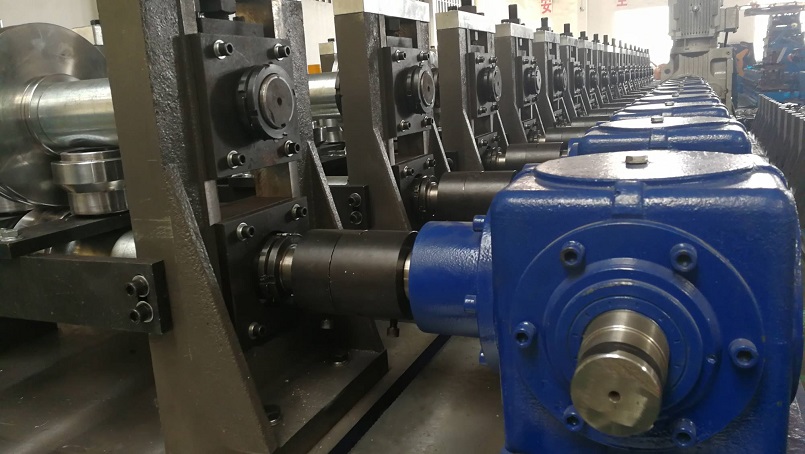

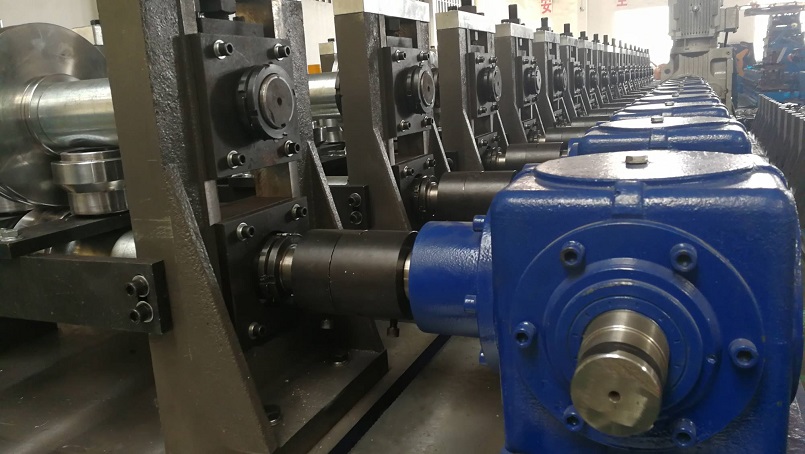

Driving

-

Chain Drive

-

Gearbox Drive

-

Gearbox Drive With Coupling

-

-

Stands

-

Wall Panel

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel For C Purlin

-

-

Punching

-

Hydraulic Punching Station

-

Punching Press

-

Roller Punching

-

-

Feeding

-

Leveling

-

Servo Feeding

-

-

Decoiler

-

Manual Decoiler

-

Hydraulic Decoiler

-

Double Head Decoiler

-