Linbay gutter roll forming machine has been exported to Russia, Australia, Philippines, Vietnam and Mexico, specially to Australia.

In rainwater goods system, we are able to manufacture more machines like gutter roll forming machine, separate elbow machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Description:

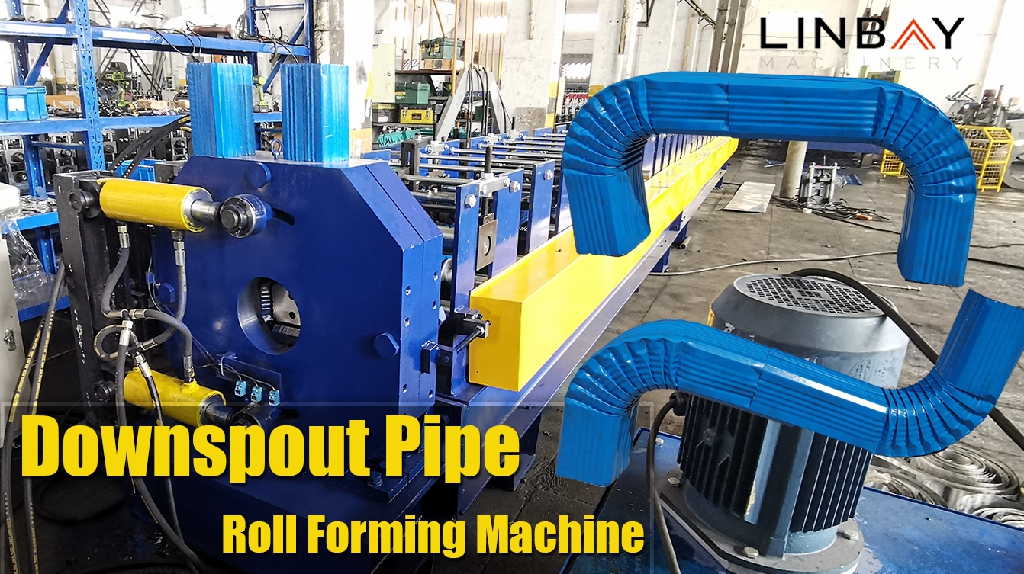

Linbay exported this round downspout pipe roll forming machine to South Africa on 2008, Australia on 2016 and to Kyrghyzstan on 2017. This configuration is affordable and practical to any company.

Description:

This square downspout pipe roll forming machine is a complete line that can produce pipe and elbow in one machine. We use servo motor as main forming power, it improves pipe’s precision. At last process, we not only offer a hydraulic cut, but also a elbow machine and a shrink device. It’s a good choice for you.

|

Downspout Pipe Roll Forming Machine |

||

|

Machinable Material : |

A) Aluminum |

Thickness (MM):0.4-0.6, 1.5-2 |

|

B) Copper |

||

|

C) Galvanized steel |

||

|

D) Painted steel |

||

|

E) Galvalume |

||

|

Yield strength : |

250 - 350 Mpa |

|

|

Tensil stress : |

300 Mpa-500 Mpa |

|

|

Decoiler : |

Hydraulic decoiler |

* Manual decoiler (Optional) |

|

Forming station : |

20-24 |

* According to your profile drawings |

|

Main machine motor brand : |

Shanghai Dedong (Sino-Germany Brand) |

* Siemens (Optional) |

|

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Wall panel station |

* Torri station (Optional) |

|

Forming speed : |

10-15 (M/MIN) |

* Or according to your profile drawings |

|

Rollers’ material : |

Steel #45 |

* GCr 15 (Optional) |

|

Cutting system : |

Post-cutting |

* Elbow mould/shrink mould (Optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (Optional) |

|

PLC brand : |

Panasonic |

* Siemens (Optional) |

|

Power supply : |

380V 50Hz 3ph |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

|

Elbow Machine Specification |

|

|

Suitable pipe thickness(MM): |

0.4-1.5 MM |

|

Machineable shape: |

round pipe/square pipe. |

|

Elbow angle : |

30° |

|

45° |

|

|

75° |

|

|

90° |

|

|

Motor power(KW) : |

2.5 KW |

|

Other function : |

Automatic shrink mould |

|

Machine size(MM): |

1200x650x1500 |

1.Q: What kinds of experience do you have in producing downspout pipe roll forming machine?

A: We have experience of exporting our gutter roll formers to South Africa, Australia, Kyrghyzstan, Russia, Southeast Asia, Mexico and etc. We have produced round and square pipe.

2.Q: What parts of rainwater system are included?

A: Rainwater system mainly consist of gutter roll forming machine and downspout pipe roll forming machine. And all product shapes can be customized according to your requirements, whether it is a square pipe, a round pipe or a heterogeneous pipe.

3. Q: How to make downspout pipe from straight to elbow?

A: There will be an elbow machine at the end of the roll forming part. It can be used as a part on the roll forming machine and also can be used as a single machine according to the customers’ requirements. It will bend the water pipe after forming downpipe, and can make any angle according to customers’ requirements(30°, 45°, 75° and 90° available)

4. Q: What is delivery time of downspout pipe roll forming machine?

A: 40 days to 50 days depends on your drawing.

5. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally line forming speed is around 12m/min.

6. Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

7. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-