0.18mm High Yield Strength Corrugated Panel Roll Forming Machine

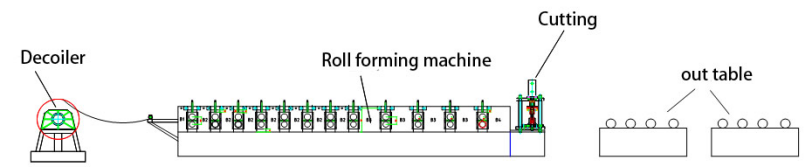

Hydraulic decoiler-Roll former-Electrical cutting-Out table

Hydraulic decoiler

Producing corrugated panels needs relatively wide steel coils, which can pose challenges during uncoiling and potential safety risks to workers. To ensure safety, a pneumatic press-arm is equipped on the decoiler to secure the coil during replacement, preventing any sudden uncoiling. Additionally, protective iron-leaves on the outer side of the coil prevent it from slipping during uncoiling, with these design features prioritizing worker safety. We also offer an optional configuration, the loading car, which helps the transport of coils onto the decoiler, saving both time and enhancing worker safety. The decoiler for roof panel production typically has a minimum weight capacity of at least 7.5 tons, with options available to meet customer demands of up to 10 tons, or more.

Roll former

In this case, we've employed the roll forming stations of wall-panel structure and a chain drive system. To safeguard both the chains and the workers, we've added a protective cover on the chains, preventing dust accumulation and providing worker protection. Given the use of high yield strength 0.18mm steel coils, a total of 24 forming stations have been integrated to ensure that the product's formation aligns with the customer's specifications.

Before forming, there are two methods for cutting: manual and electric. The electric option offers advantages in terms of precision, efficiency, and safety. In contrast, manual cutting requires workers to use scissors, potentially posing risks of cuts or injury to workers' clothing and bodies.

Hydraulic cut

Our hydraulic cutting machine derives robust cutting power from the motor. The cut edges of the profiles are smooth, without any burrs. Through precise control via PLC and encoders, the machine controls the length error within 0.5mm. We also offer a hydraulic type(Shown in the pic), with configurations tailored to customer needs and steel coil thickness.

Auto stacker

Given the width and weight of corrugated panels, we provide customized out tables to accommodate varying panel widths based on customer requirements. Furthermore, we offer an auto stacker that operates fully automatically, reducing manual labor costs and enhancing overall efficiency. After cutting, the corrugated panels are conveyed to the stacker's swinging arms, which gently layer the panels. Then the corrugated panels are transported outward along a conveyor.

Linbay is committed to providing extensive customization services, ensuring that we tailor solutions to match each customer's specific requirements. You'll find an option that perfectly suits your needs.

Description:

This barrel corrugated roll forming machine was exported to Indonesia. It’s suitable for steel panel with thickness 0.14-0.30mm very thin sheets. It’s small, easily-operated, economical and affordable.

Decoiler--Roll former--Roller 2--Hydraulci cut --Wastage collector--Out Table

|

Corrugated Roof Panel Roll Forming Machine |

||

|

Machinable Material : |

A) Galvanized Coil |

Thickness(MM):0.3-0.8 |

|

B) PPGI |

||

|

C) Aluminum Coil |

||

|

Yield strength : |

200 - 350 Mpa |

|

|

Tensil stress : |

200 Mpa-350 Mpa |

|

|

Nominal forming speed(M/MIN) |

0-20 |

* Or according to your requirement (Optional) |

|

Forming station : |

18 stands |

* According to your profile drawings (Optional) |

|

Decoiler : |

Manual decoiler |

* Hydraulic decoiler (Optional) |

|

Punching system |

No |

* Hydraulic punching (Optional) |

|

Main machine motor brand : |

Sino-Germany Brand |

* Siemens (Optional) |

|

Driving system : |

Chain drive |

* Gearbox drive (Optional) |

|

Machine structure: |

Wall panel station |

* Forged Iron station or torri stand structure (Optional) |

|

Rollers’ material : |

Steel #45 |

* GCr 15 (Optional) |

|

Cutting system : |

Post-cutting |

* Pre-cutting (optional) |

|

Frequency changer brand : |

Yaskawa |

* Siemens (optional) |

|

PLC brand : |

Panasonic |

* Siemens (optional) |

|

Power supply : |

380V 50Hz |

* Or according to your requirment |

|

Machine color : |

Industrial blue |

* Or according to your requirment |

1.Q: What kinds of experience do you have in producing roof panel roll forming machine?

A: Roof/wall panel (corrugated panel) roll forming machine is the most produced machine, we have many experience of this machine. We have exported to India, Spain, UK, Mexico, Peru, Argentina, Chile, Bolivia, Dubai, Egypt, Brazil, Poland, Russia, Ukraine, Kazakhstan, Bangladesh, Bulgaria, Malaysia, Turkey, Oman, Macedonia, Cyprus, USA, South Africa, Cameroon, Ghana, Nigeria etc.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, furring channel roll forming machine, ceiling T bar roll forming machine, wall angle roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

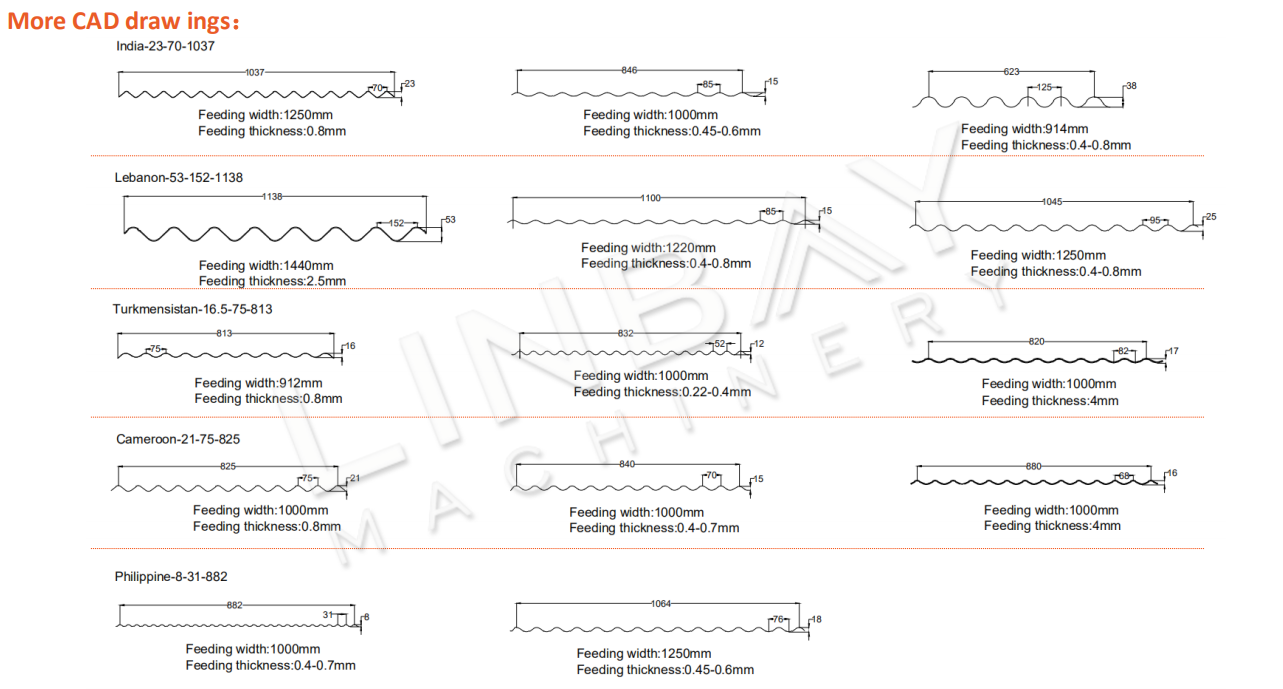

2.Q: How many profiles can produce this machine?

A: According to your drawing, specially the height and pitch of each wave, if they are the same, you could produce several sizes with different feeding coil width. If you want to produce one trapezoidal panel and one corrugated panel or a roof tile, we would recommend you a double layer roll forming machine to save your space and cost of machine.

3.Q: What is delivery time of corrugated roof panel roll forming machine?

A: 45 days to design from beginning to lubricate all rollers before shipment.

4.Q: What is your machine speed?

A: Our forming speed is 0-20m/min adjustable by Yaskawa frequency changer.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-