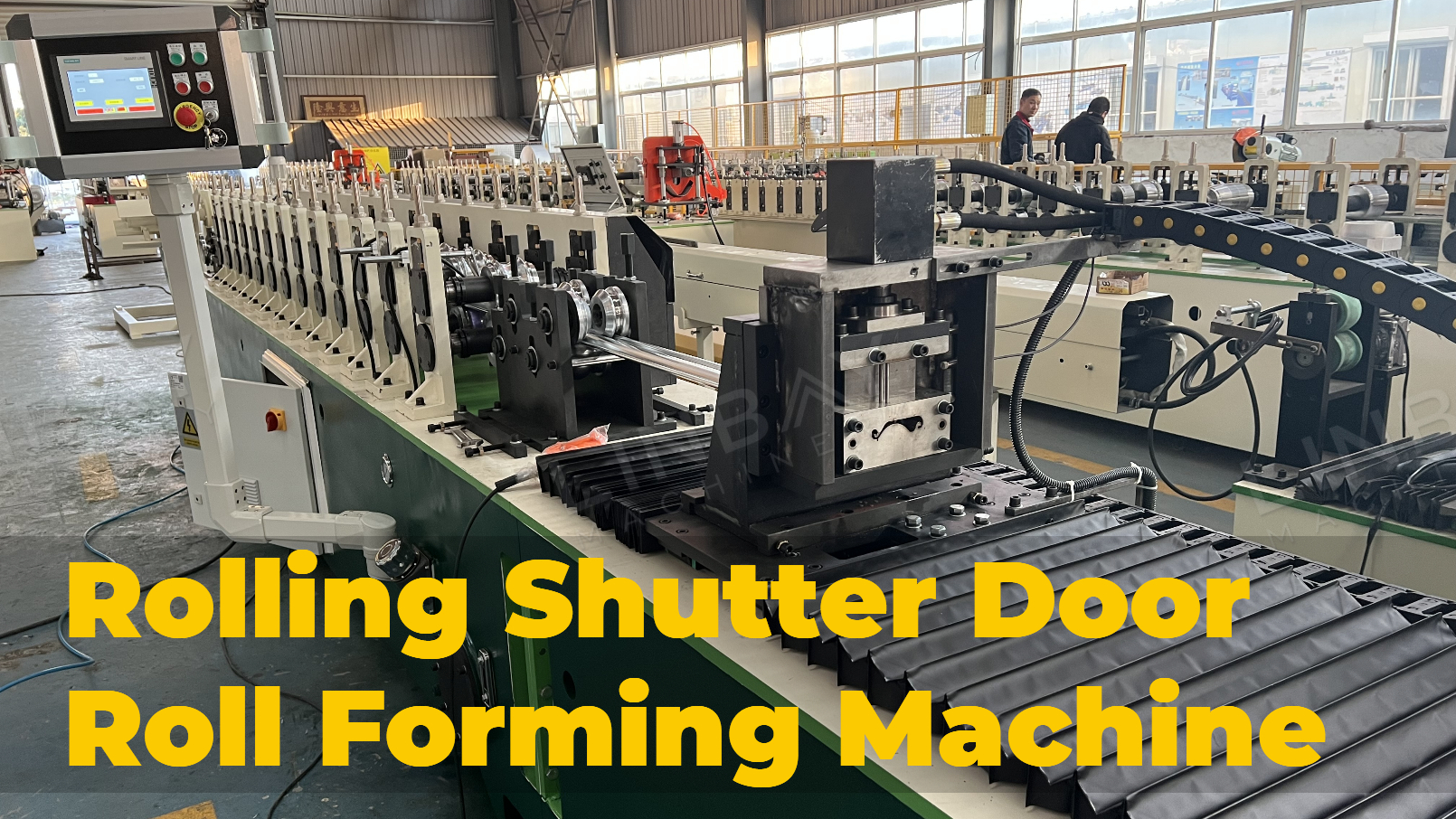

Flying Cutting Rolling Shutter Door Roll Forming Machine

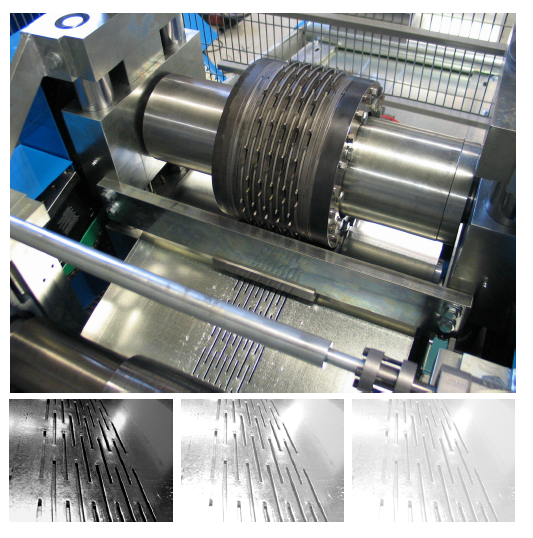

Roller shutter slat come in various sizes and designs, it can be punched according to the purpose of ventilation and lighting. And it can also be embossed with decorative patterns to enhance visual appeal. It is usually made of galvanized steel and galvalume steel, with the thickness range of 0.6-0.8mm and 0.8-1.0mm.

We offer tailored solutions to match your specific requirements, ensuring a customized roll forming configuration that perfectly suits your needs.

Flow chart

Hydraulic decoiler-Guiding-Roll former-Flying cut-Out table

Hydraulic decoiler

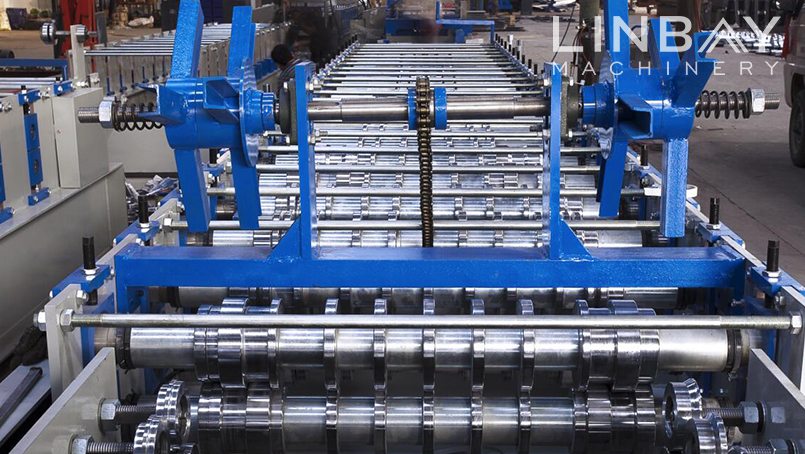

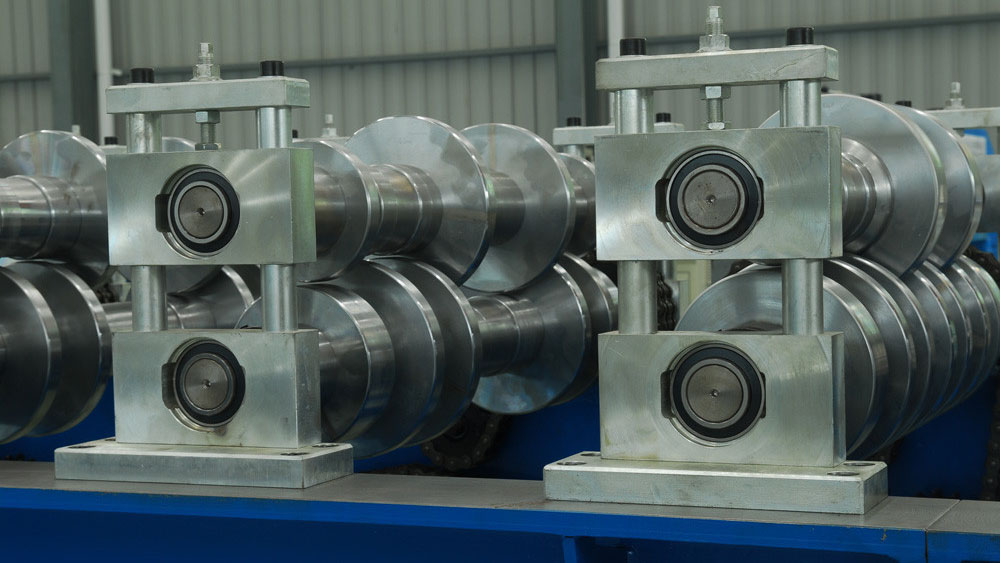

Guiding

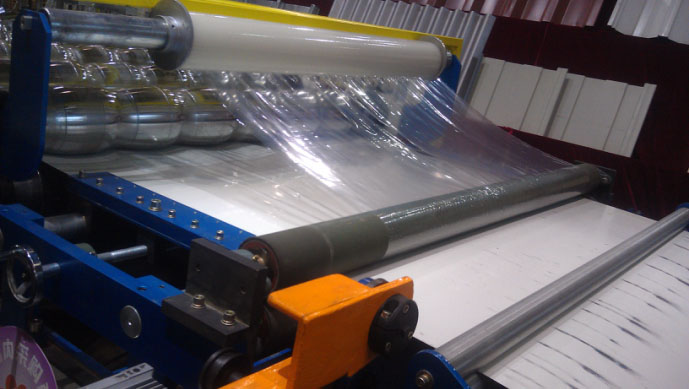

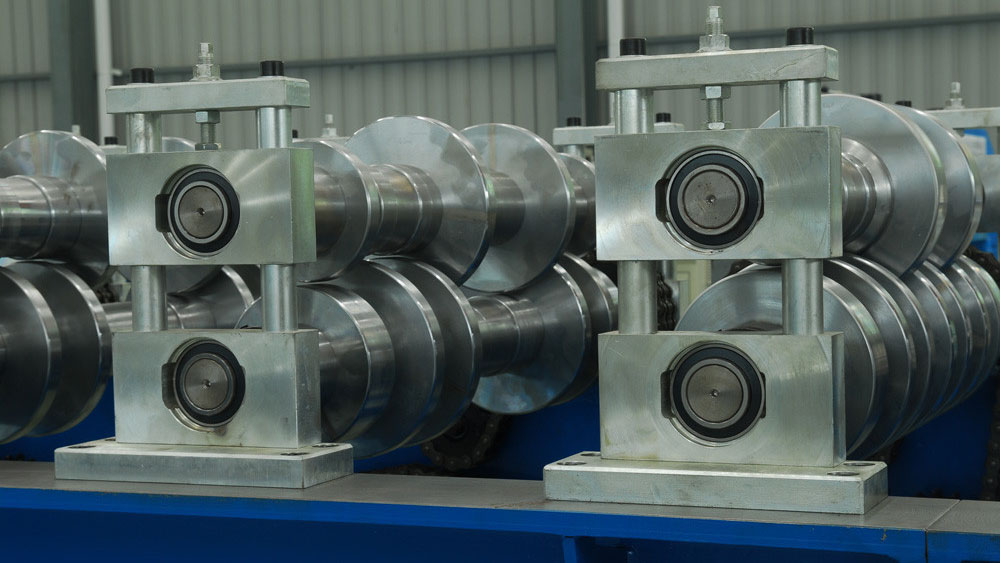

Each machine within the production line must be meticulously positioned to maintain the steel coil consistently along a central line, ensuring that the rolling shutter slats remain free from distortion. Therefore, the simple guiding part plays a pivotal role. Multiple guiding rollers are strategically set throughout the production line to fulfill this critical function.

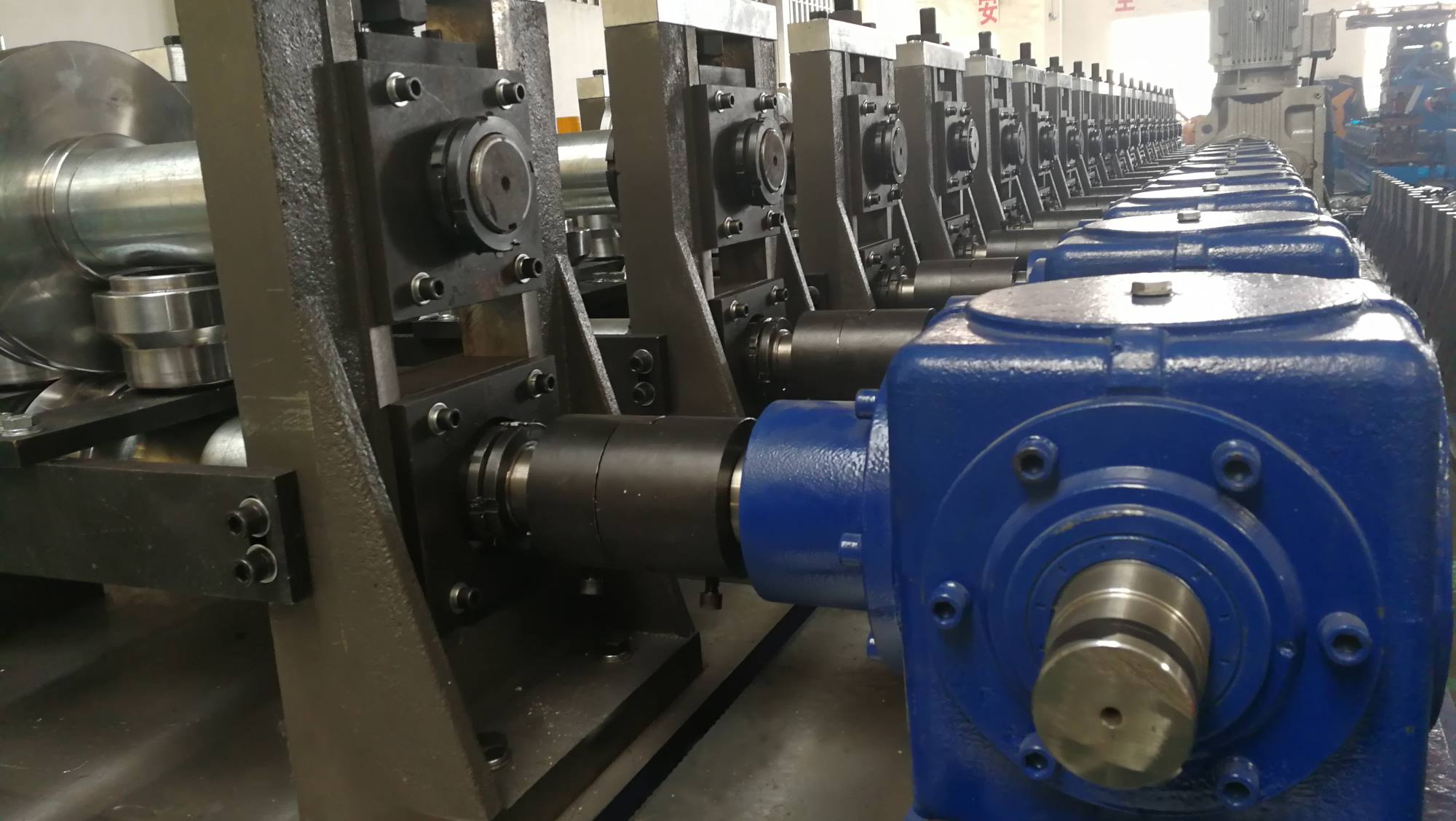

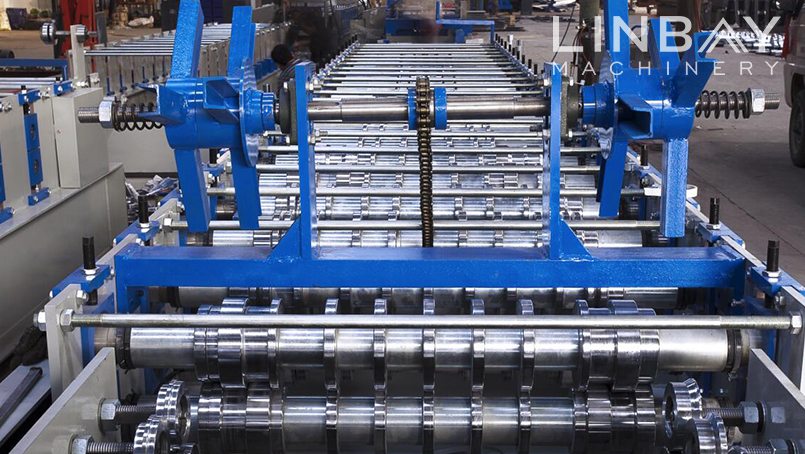

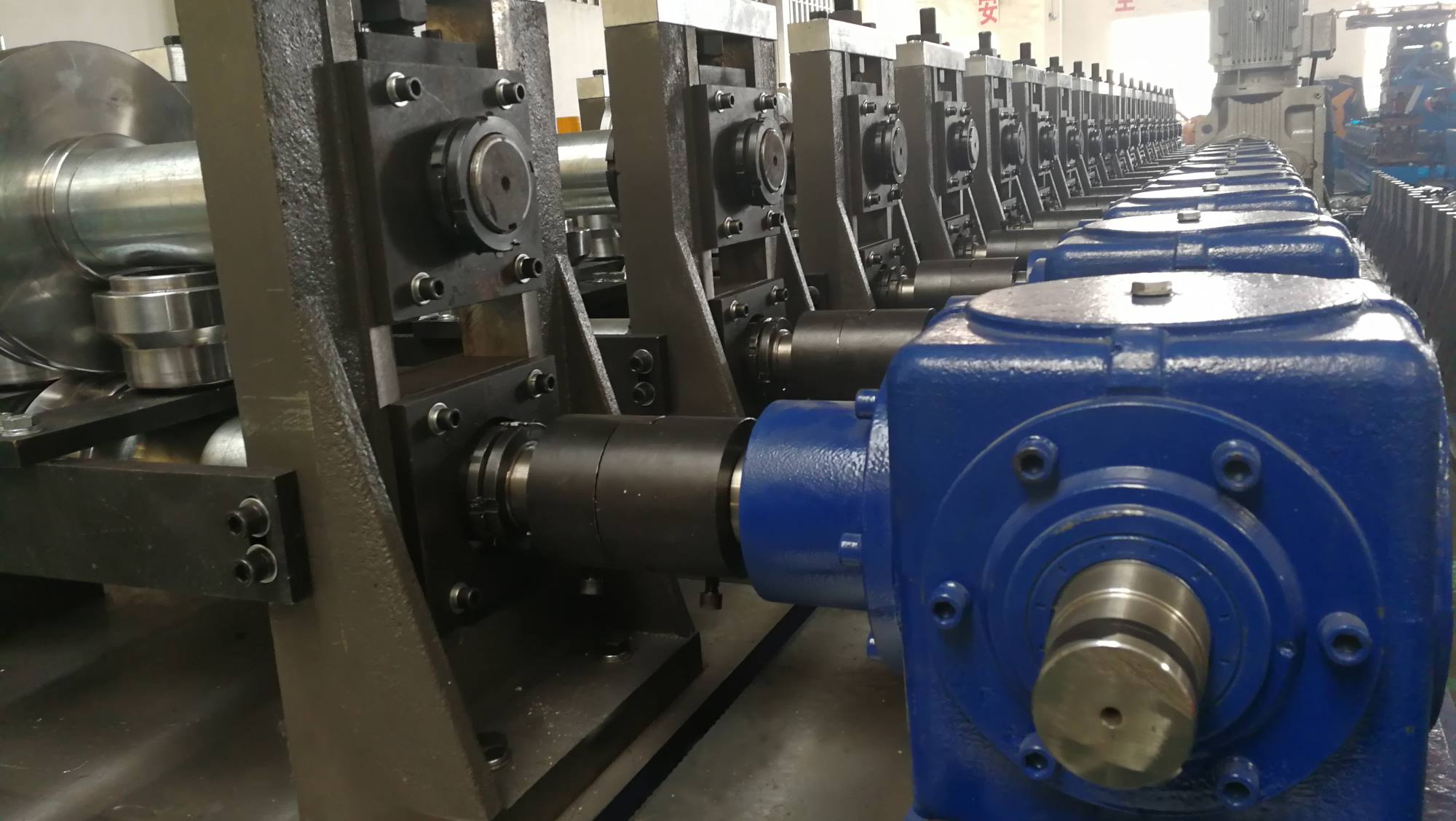

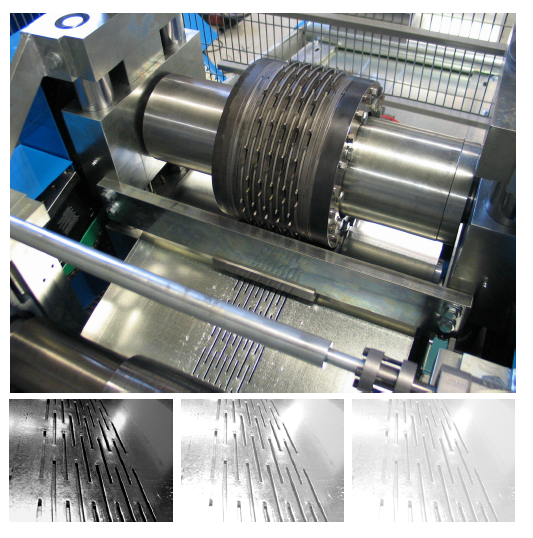

Roll former

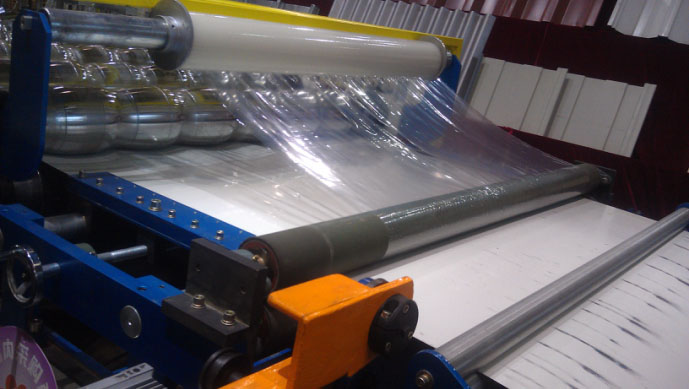

Prior to the forming process, a cooling system is implemented to help reduce the temperature of rollers, while also protecting the surface of the steel coil. The machine's cast-iron structure is a complete piece of steel, ensuring stability throughout the forming process and an extended lifespan. The forming rollers are driven by gears, efficiently transferring power from the motor to the rollers. Additionally, we have equipped a protective cover on the gears to ensure the safety of both workers and the machines.

It should be noted that the size, shape, and placement angle of the forming roller will affect the forming point of the profile, so a rolling shutter slat profile requires a roll forming machine. But in order to optimize the solution, we have also launched a double-row roll forming machine, which can save costs.

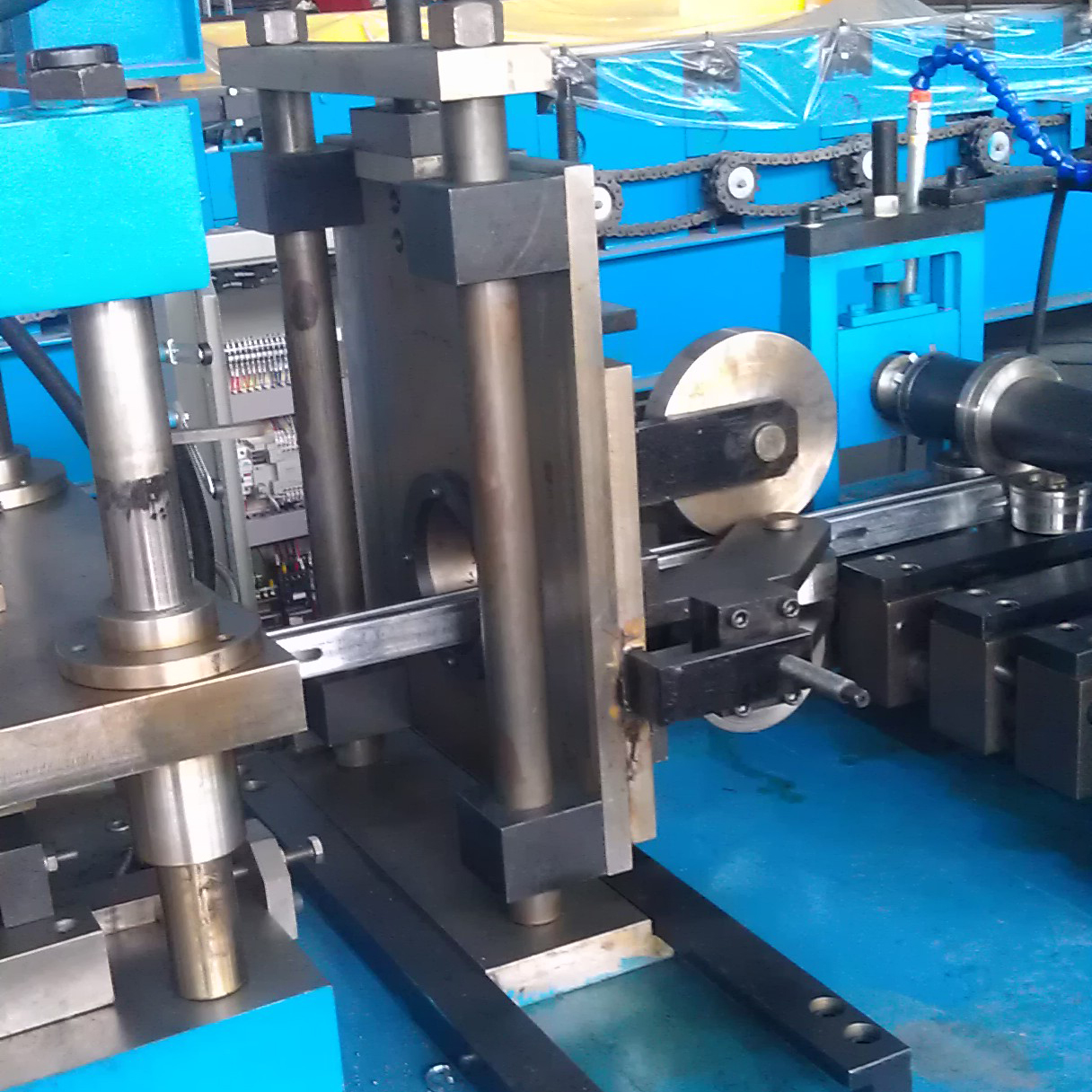

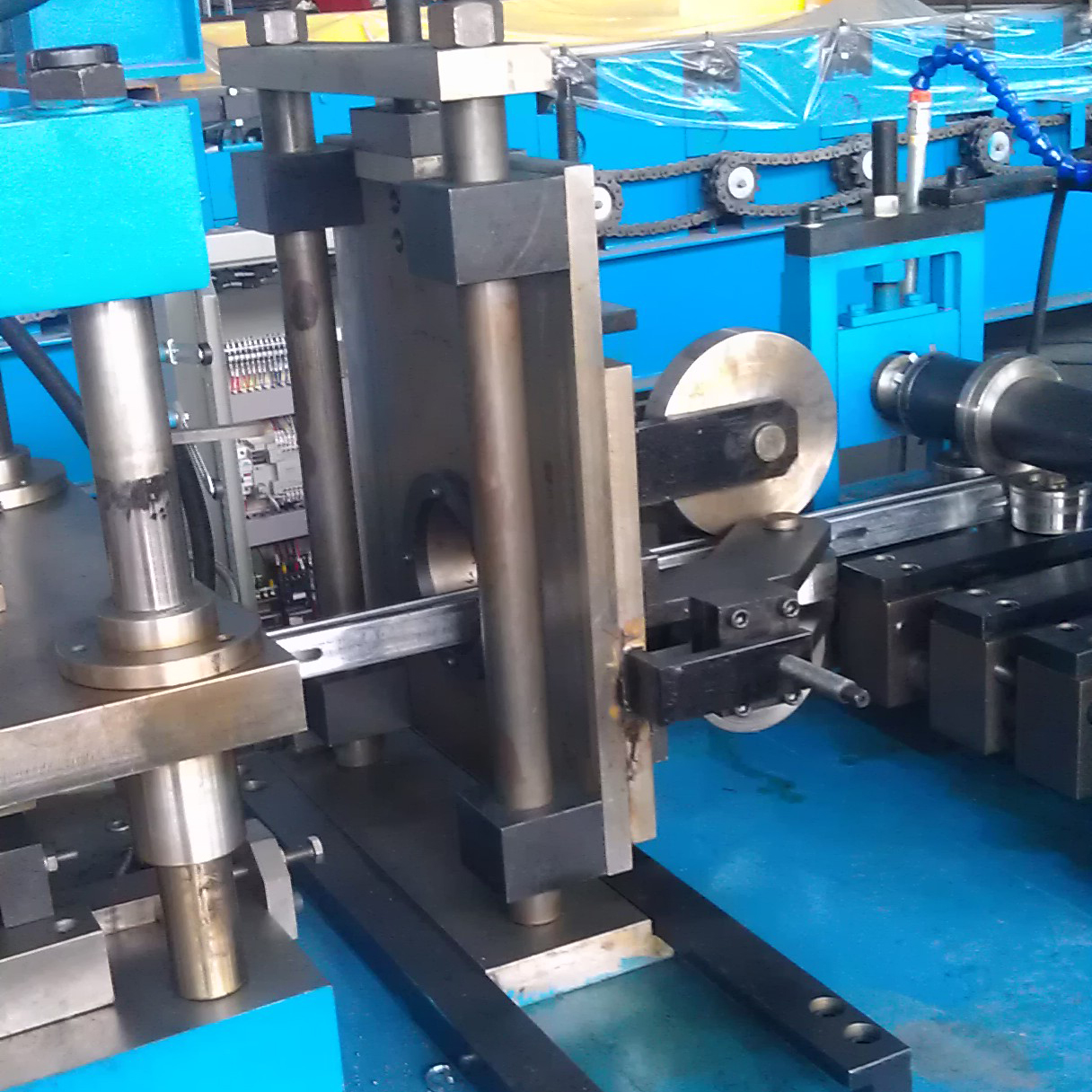

Flying cut

We utilize a Yaskawa motor to drive the movement of the cutting base, ensuring non-stop cutting at a production speed of 15m/min. Inside the roll forming machine, an encoder records the advancing distance of the steel coil, enabling machines to precisely control cutting lengths within an error of ±0.5mm.

This accuracy is maintained through the PLC control cabinet, where inputting the desired cutting length on the screen leads to precise and efficient cutting operations.

|

Rail/Door track roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):1.5-2.5 |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

10-20 |

Or according to your requirement |

|

3 |

Forming station |

17 |

According to your profile |

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Torri stand structure |

Forged Iron station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

Manual decoiler--leveling--forming machine--hydraulic cutting--out table

-

Others

-

scrap collector

-

pasting

-

mould change

-

guiding head

-

Cooling system

-

-

Out table

-

non-powered

-

auto stacker

-

-

Cutting

-

saw cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for Cpurlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)