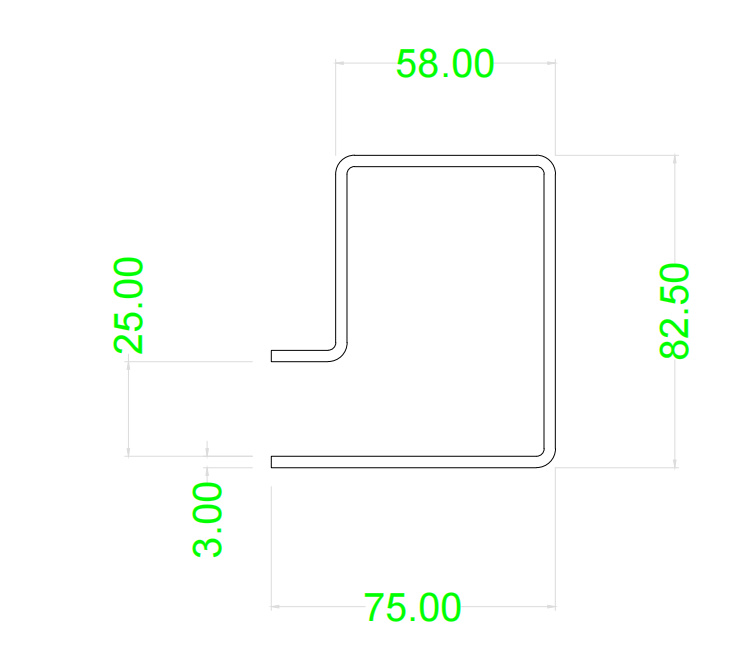

The rolling shutter door rail roll forming machine has been designed for producing steel guide rails for roller shutter doors to open up and close down.

Due to the heavy duty materials a rolling shutter door rail roll forming machine usually bends, there are two types of transmission available for customers to choose: Chain-brackets transmission and Gear-box transmission.

And here we prefer our customers to adopt the gear box drive. Because it can withstand more pressure, ensure the whole production process a higher working efficiency. It’s made of several gear boxes and universal joint drive for each box with the iron cast structure. Also it can be very favorable for later maintenance cause they are separate. So the iron cast and gear box match group offers you the best and strongest configuration for the entire process.

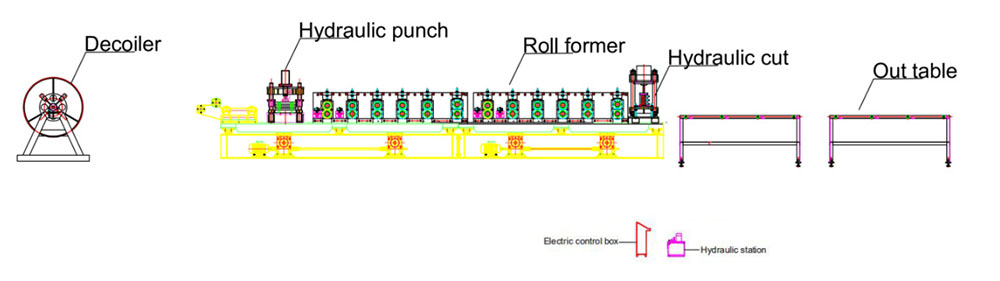

This rolling shutter door rail roll forming machine for the production of 3mm wind resistant rolling shutter door guide rails consists of a decoiler, guide, hydraulic punch, main roll forming machine, transmission system (chain-brackets or gearbox), shearing, hydraulic oil pump, PLC control cabinet and out tables.

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)