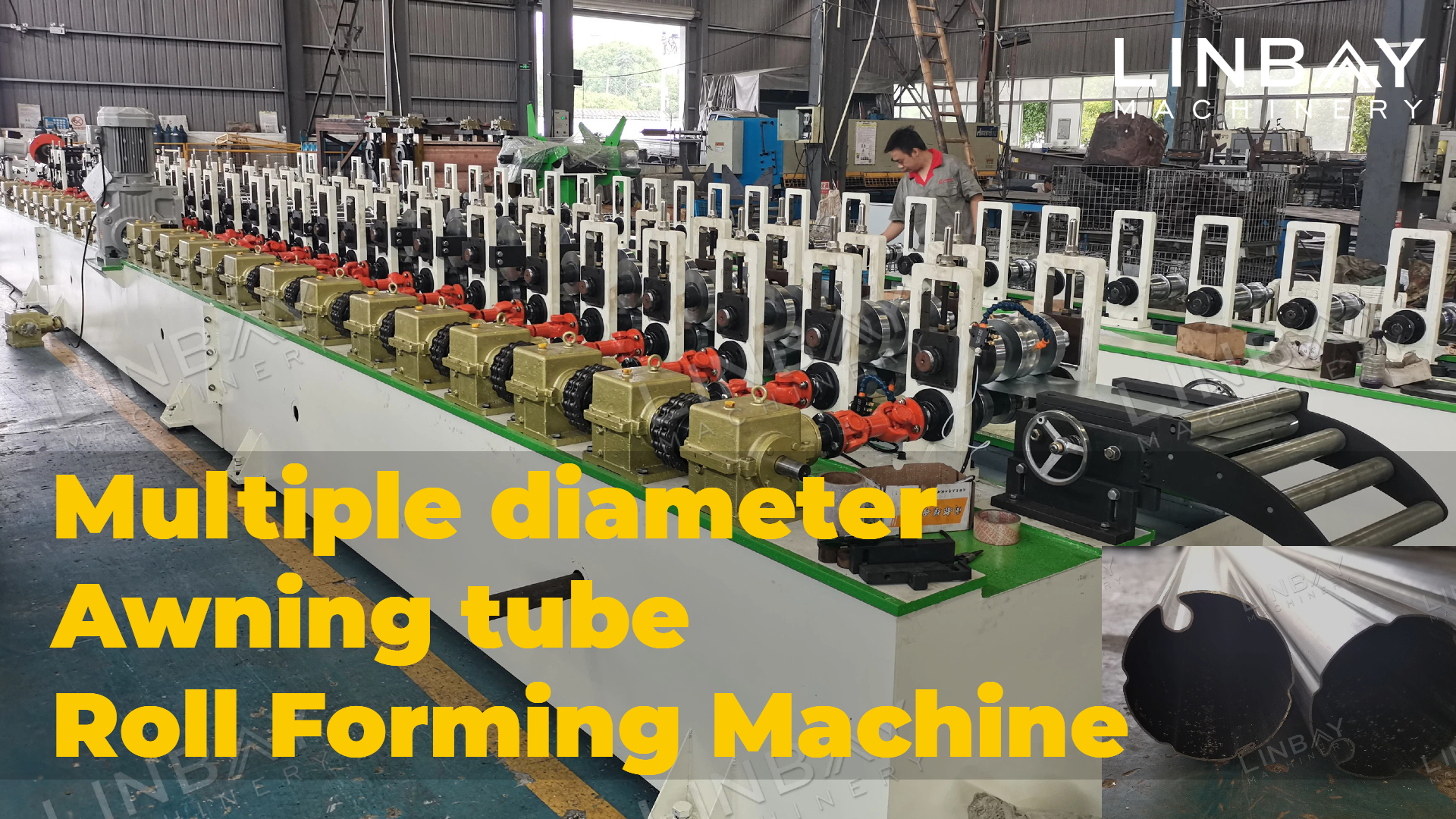

Multi-diameter steel awning round tube roll forming machines

Awning round tubes are used in conjunction with awnings. These round tubes are typically made of aluminum or galvanized steel, with common diameters of 60/63/70/78/80/85mm and standard lengths of 4/5/6/7 meters.

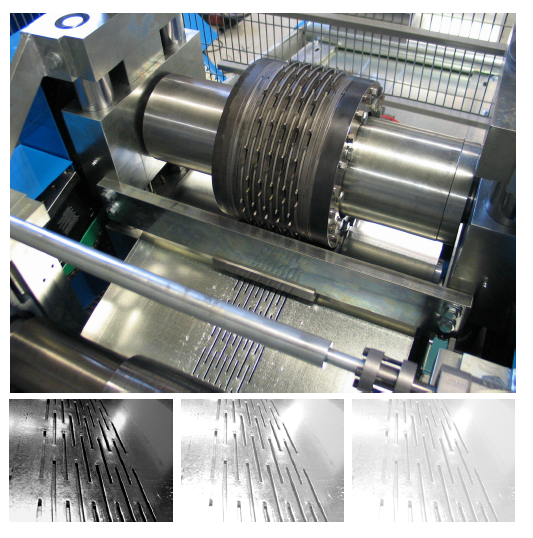

Traditional production solution: Steel coils are wrapped around a cylindrical form and then pressed to create a round tube. This method applies uneven force, has low production efficiency, and is limited in terms of tube length and minimum diameter. Additionally, it's challenging to form tubes with non-standard round edge designs, like the image below.

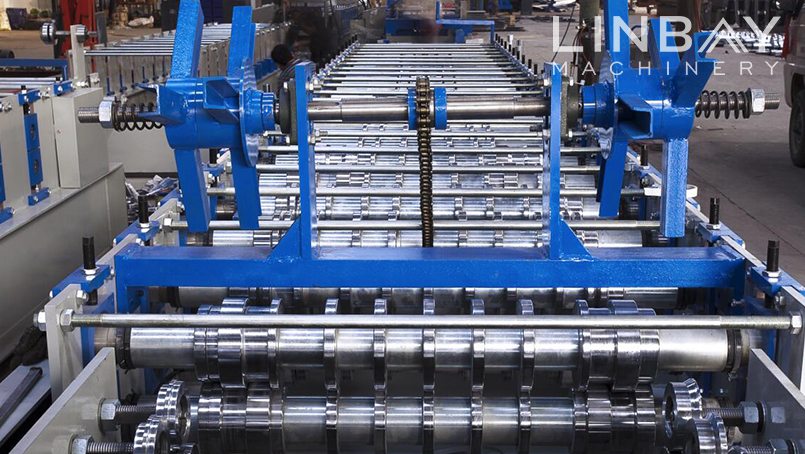

New solution: Roll forming machine. Each forming roller forms and shapes the material a small angle at a time until it becomes round and securely lock-seamed. The even application of force helps prevent springback.

Steel coils can be fed continuously into the machines without manual pre-cutting. The cut lengths can be freely selected with an accuracy within ±1mm. This method allows the production of tubes with smaller diameter and non-standard edge designs. It's an automatic and cost-saving choice for clients.

Decoiler--Guiding--Roll former--Flying saw cut--Out table

1.Line speed: 0-10m/min, adjustable

2.Suitable material: Galvanized steel, aluminum

3.Material thickness: 0.8-1mm

4.Roll forming machine: Cast-iron structure

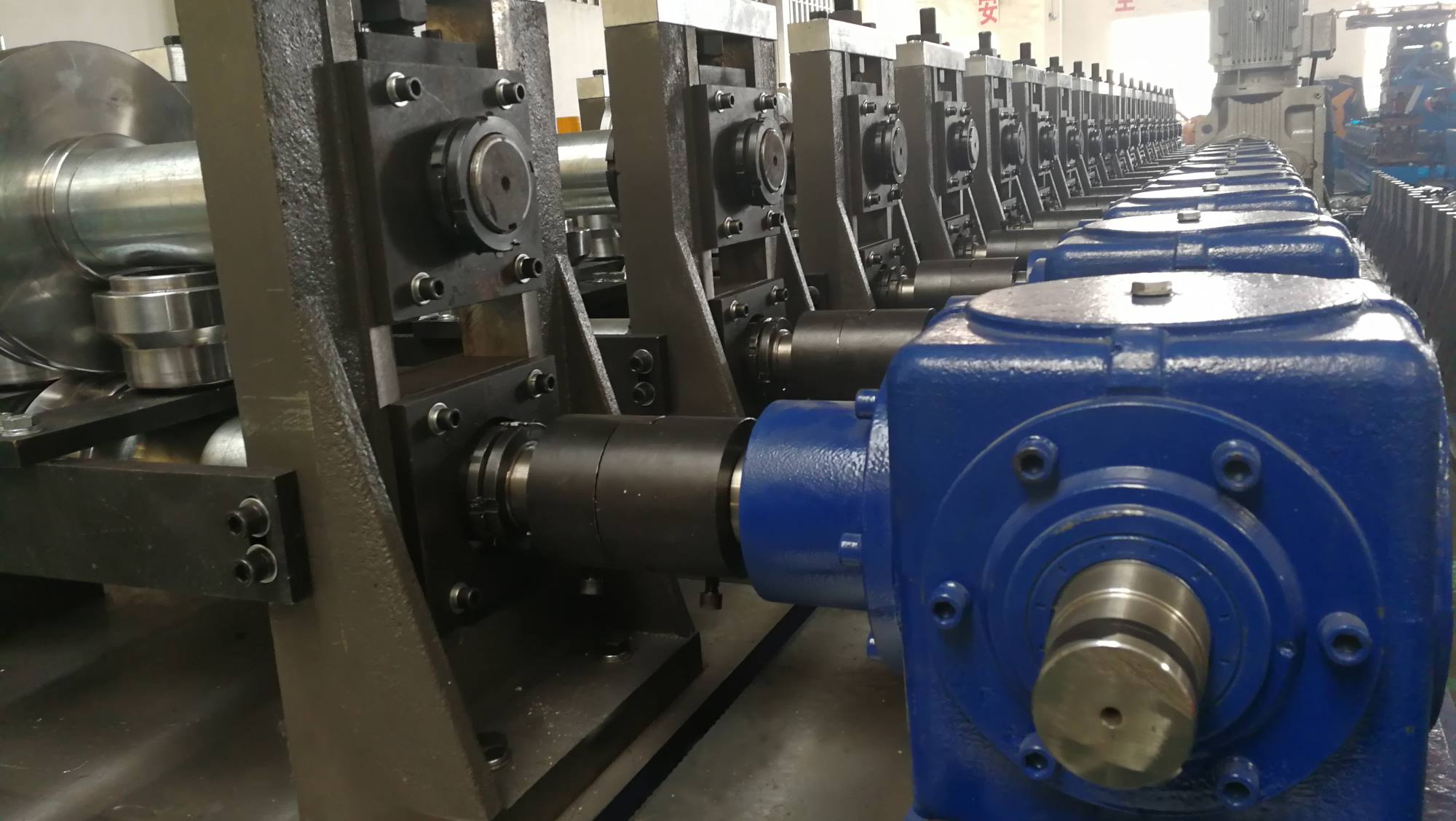

5.Driving system: Gearbox driving system with universal joint cardan shaft.

6.Cutting system: Flying saw cut, roll former doesn’t stop when cutting.

7.PLC cabinet: Siemens system.

1.Manual Decoiler*1

2.Roll forming machine*1

3.Flying saw cutting machine*1 (Including saw blade*1)

4.Out table*2

5.PLC control cabinet*1

6.Hydraulic station*1

7.Spare parts box(Free)*1

Manual Decoiler

* Frame: Stable and robust, designed to hold steel coils.

* Core Expansion Device: Manually adjusted mandrel or arbor expands to fit steel coils with an inner diameter of 490-510mm, ensuring smooth decoiling by securely gripping the coil.

* Coil Retainer: Prevents the steel coil from slipping off the mandrel, easily attachable and removable.

* Optional Types: Electric orhydraulic version is available for more power and automated core expansion. However, for awning round tube, a manual version is used due to the thinner and narrower steel coil being handled.

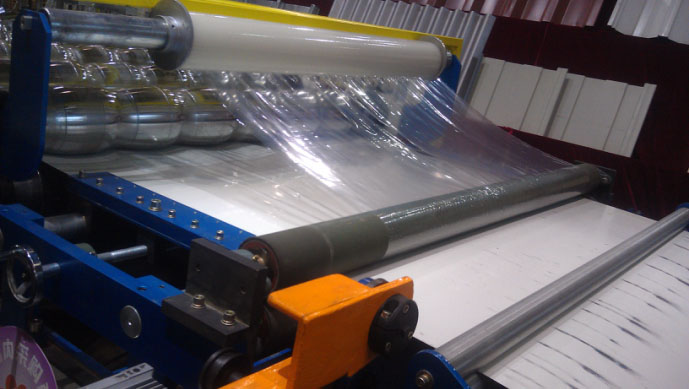

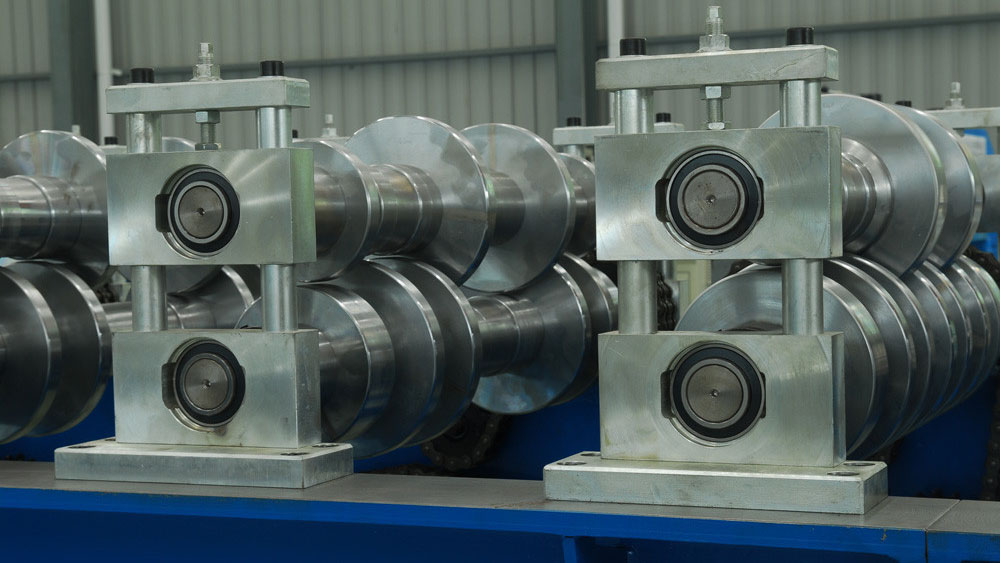

Guiding

* Main Function: Ensures the steel coil aligns with the machine's centerline to avoid misalignment, which can cause twisting, bending, and burrs. Proper alignment ensures tight and secure seam connectionsof the awning round tubes.

* Multiple Guiding Devices: Not only at the feed entrance but also throughout the forming machine to maintain straightness of the tube.

* Periodic Calibration: Guiding devices should be regularly calibrated after transportation bumps and prolonged use.

* Pre-Delivery Measurement: Linbay team measures and records the guiding width in the user manual for timely calibration upon receipt.

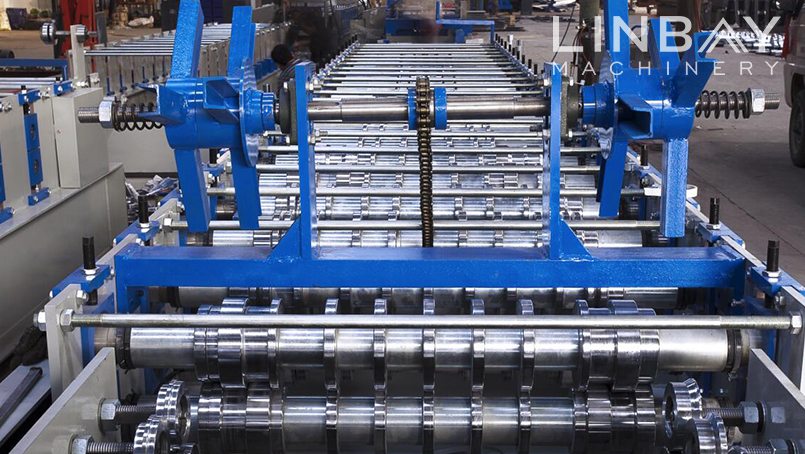

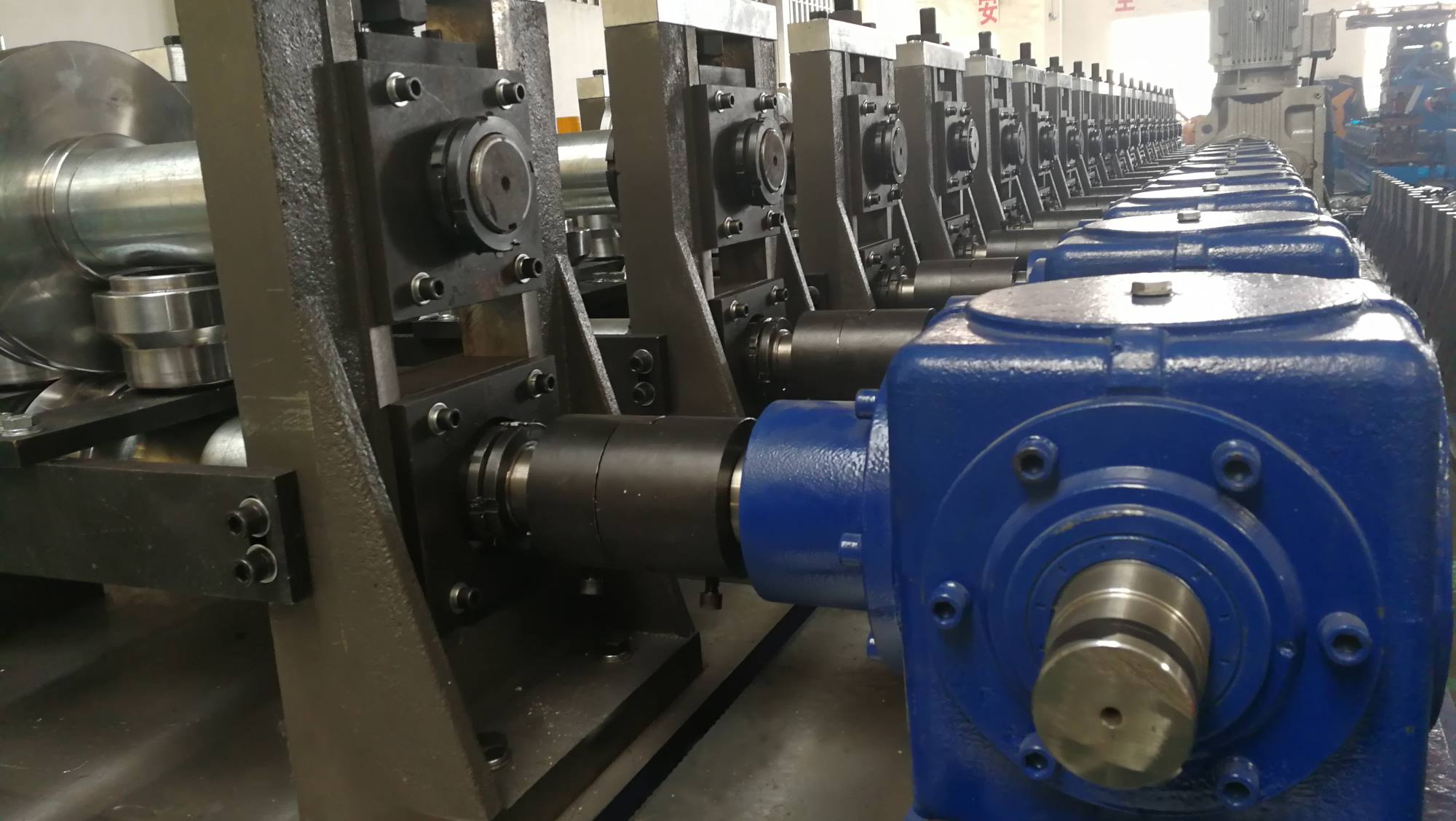

Roll Former

* Sturdy Structure: Cast-iron stand.

* Gearbox & Universal Joint: Provide powerful drive to the rollers, ensuring smooth forming of the steel coil.

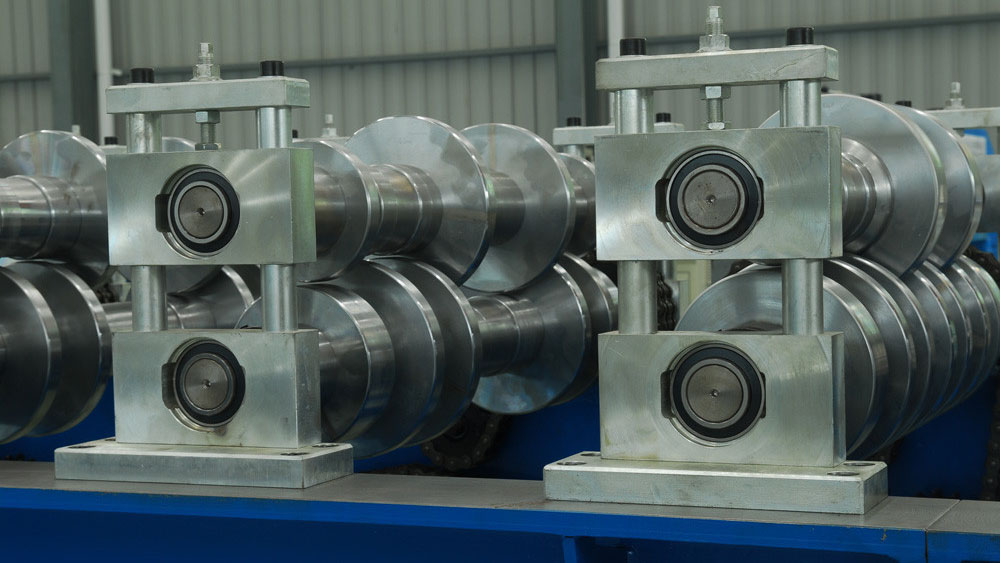

* Versatile Production: Uses a single roll forming machine base with different cassettes designed for various round tube diameters. Simply hoist the appropriate cassette to produce round tubes of different diameters.

* Cost-Effective: Saves significant costs compared to purchasing separate production lines for awning tubes of differentdiameters.

* Tight Lock Seam: Ensures the seam is very tight and won't break open.

* Efficient and Eco-Friendly Cooling System: Recirculates coolant to lower roller temperature, maintaining superior forming performance. Over time, this also extends the lifespan of the rollers.

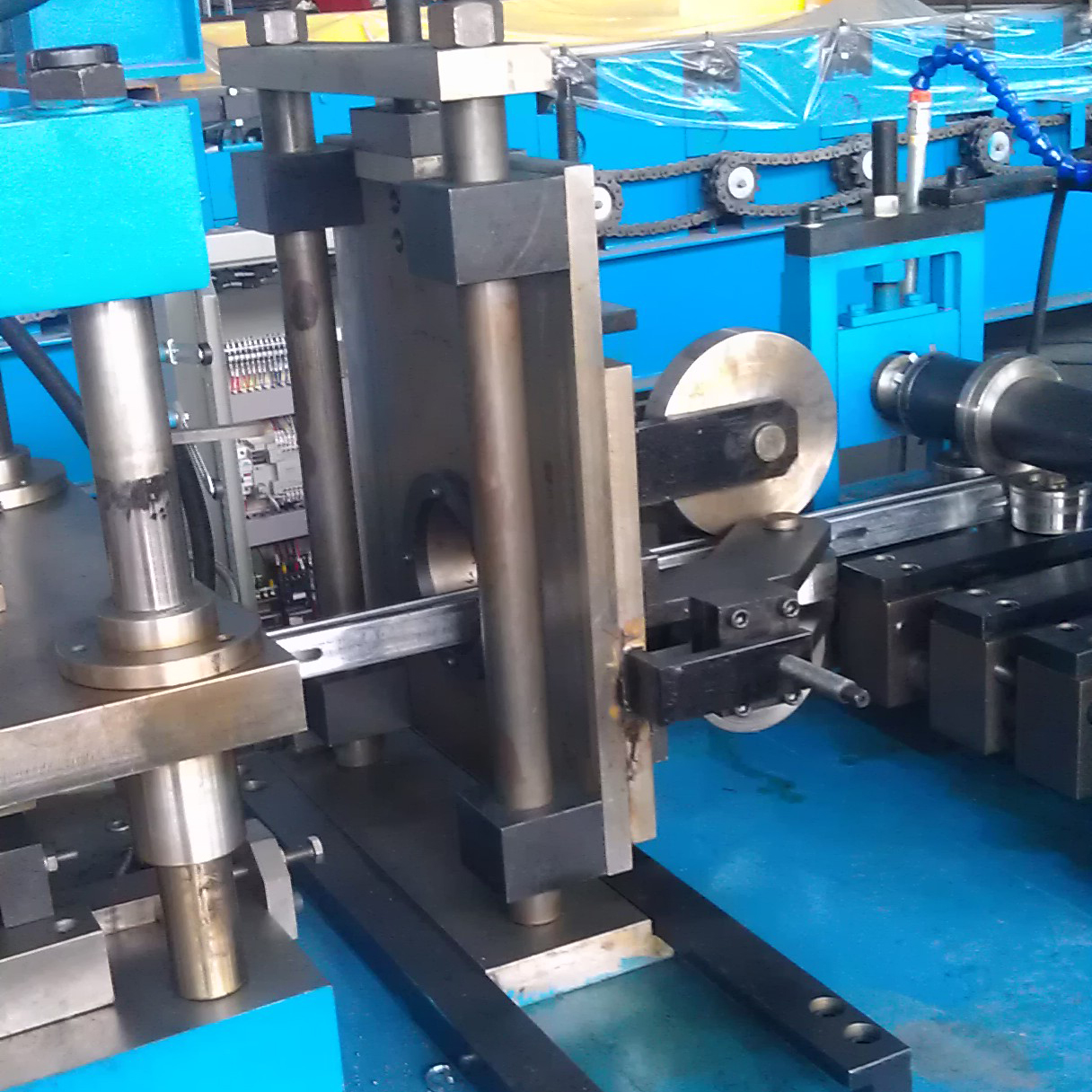

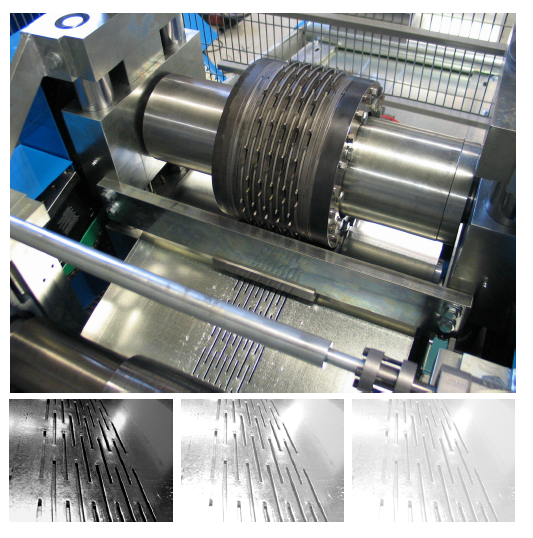

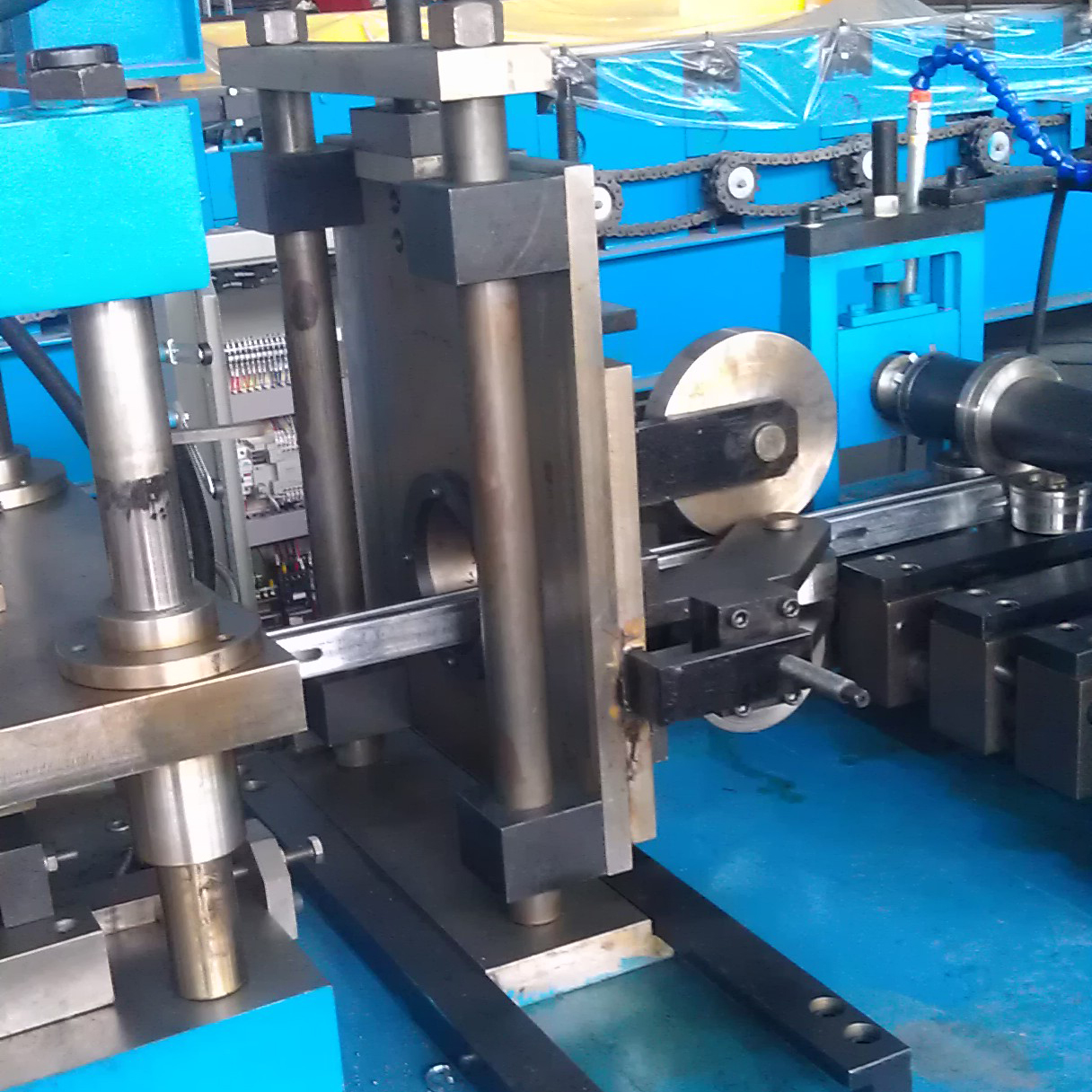

Flying Saw Cut

* Versatile Saw: Compatible with multiple round tube diameters, reducing blade costs.

* Clean Cuts: Less likely to deform the cut edge, producing smooth, burr-free cuts.

* Material Savings: No material waste with each cut, saving on steel coil costs.

* Increased Production Speed: The cutter unit moves along a track to match forming speed, allowing continuous operation of the forming machine.

* High Precision: Equipped with a servo motor and motion controller, achieving cutting accuracy within ±1mm.

* Coolant Recirculation: Lowers saw blade temperature to maintain excellent cutting performance during continuous operation. This also helps to extend the blade's lifespan.

Technical specification

|

Steel Strut& Rail roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):1.5-2.5 |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

10-20 |

Or according to your requirement |

|

3 |

Forming station |

17 |

According to your profile |

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Torri stand structure |

Forged Iron station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

More Pictures

-

Others

-

scrap collector

-

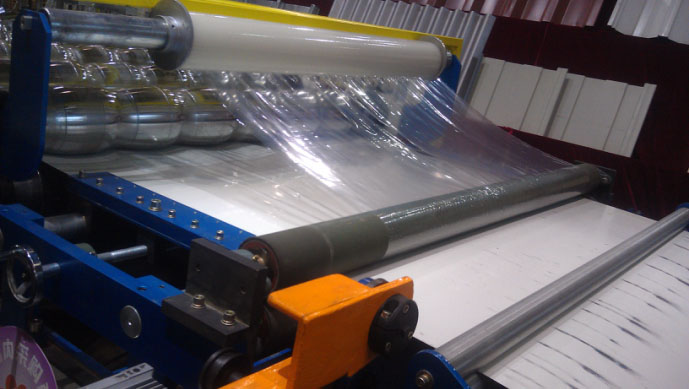

pasting

-

mould change

-

guiding head

-

Cooling system

-

-

Out table

-

non-powered

-

auto stacker

-

-

Cutting

-

saw cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for Cpurlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)