Efficient, Reliable, and Customized

Our Roll Forming Machine for Metal Shutter Guide Rails is designed to manufacture high-quality guide rails, widely used in commercial and industrial rolling shutter systems throughout USA.

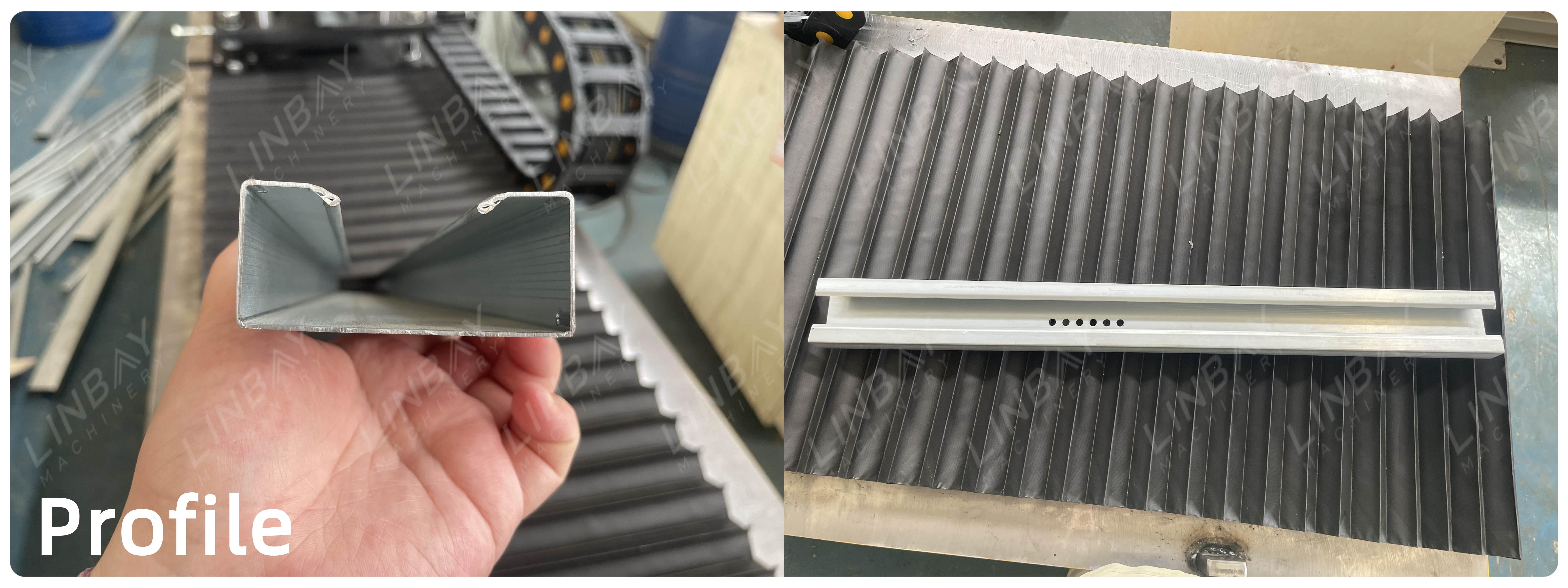

This production line can form standard guide profiles, using galvanized sheets in Gauge 14 (≈2.0 mm) and Gauge 16 (≈1.5 mm), meeting the most common specifications of the local market.

|

Type |

Material |

Common Thickness (Gauge / inch) |

Typical Dimensions (inches) |

|

Industrial Door Track |

Galvanized Steel |

14 Gauge (approx. 0.0747") |

1.75" x 2.25" x 14' length |

|

Commercial Door Track |

Galvanized Steel |

16 Gauge (approx. 0.0598") |

2" or 3" width |

|

Sliding Barn Door Track |

Powder-coated or Stainless Steel |

1/4" (approx. 6.35 mm) |

78.75" or 100" length |

|

Rolling Grille Track |

Hot-rolled Steel or Extruded Aluminum |

14 or 11 Gauge (0.0747"–0.1196") |

Custom sizes based on door width |

|

Automatic Door Track |

Stainless Steel |

1/8" (approx. 3.18 mm) |

42" W x 37" H (example) |

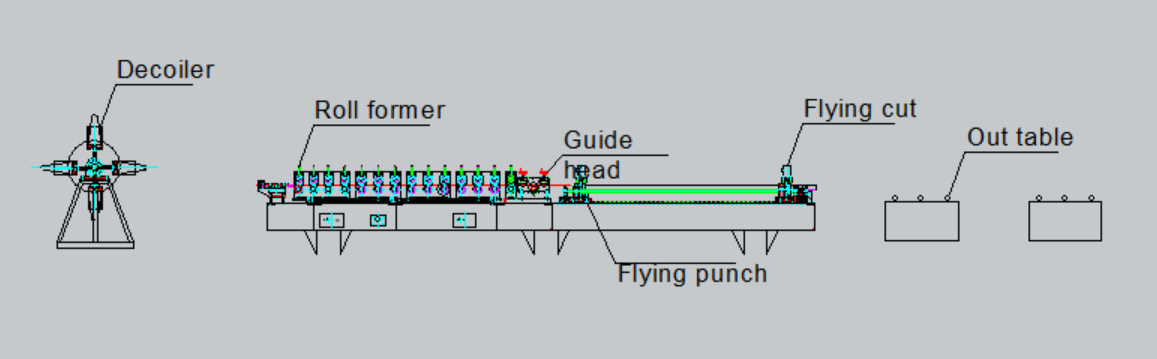

Manual Decoiler – to easily feed the steel coils.

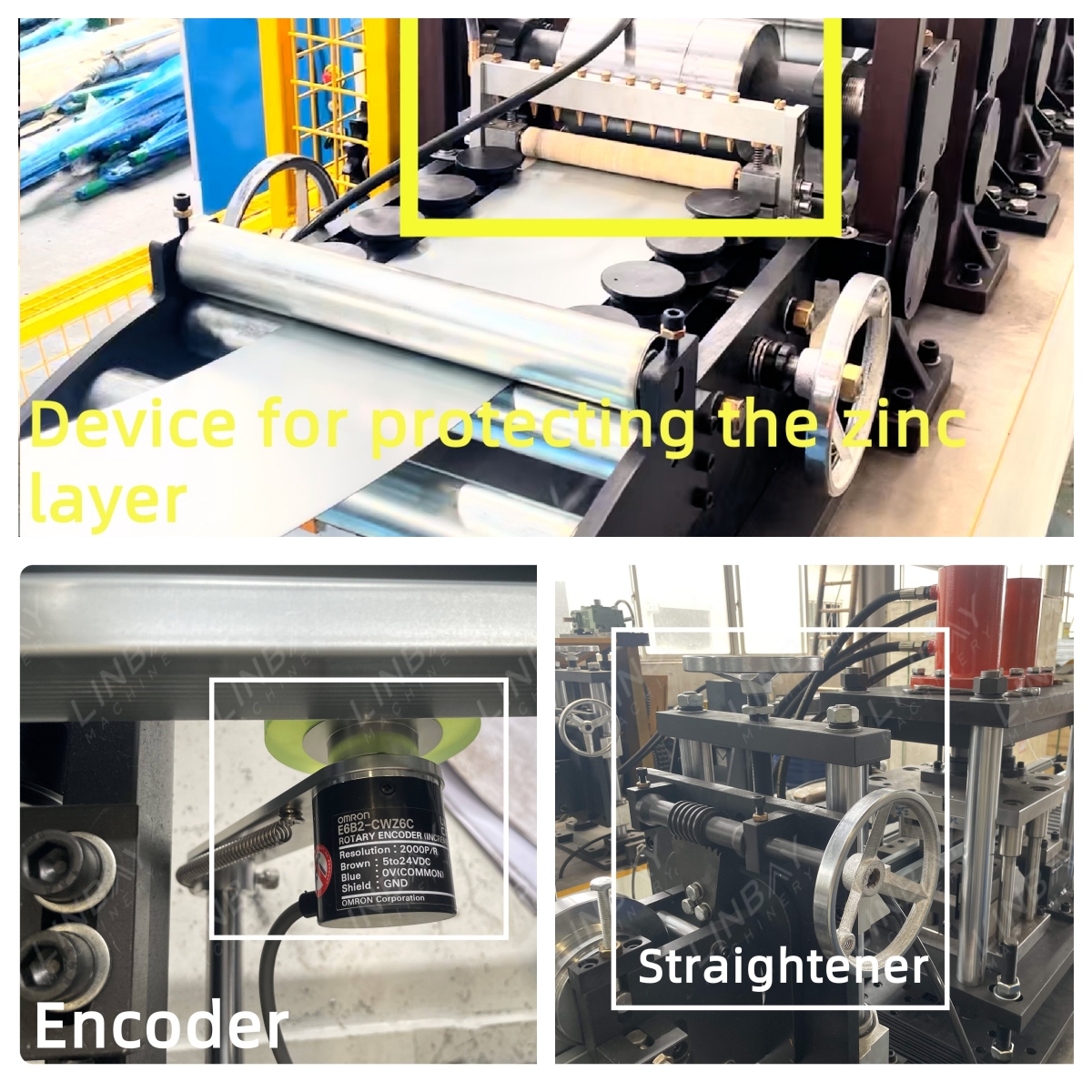

Roll Forming Machine with Chain Drive and Cast Iron Structure – zinc coating protection device, stable and precise profile forming, and straightener to ensure profile straightness.

Servo Tracking Punching – performs precise punching while the material is in motion, without stopping the line.

Servo Tracking Cutting – cuts the profile to the desired length continuously, with clean edges and no interruptions.

Stability and Robustness: Its cast iron structure with chain drive ensures long-lasting, vibration-free performance.

Precision in Punching and Cutting: The synchronized servo system guarantees high accuracy and reduced material waste.

Easy to Operate: Intuitive control panel and optimized workflow, ideal for both new and experienced operators.

Tracks for metal shutters

Security doors and window blinds

Warehouses, retail stores, garages, factories, and more

If you are a manufacturer of metal shutters or looking to start producing tracks, this roll forming line offers you a cost-effective, efficient, and low-maintenance solution tailored to your needs.

| Roll Forming Machine for Shutter Side Rails with Continuous Punching and Cutting System | ||

| Item | Optional configuration | |

| Raw materia: | Galvanized steel | Thickness (MM): gauge16, gauge14 / 1.5mm, 1.9mm |

| Yield strength: | ≤350 Mpa | |

| Line speed: | 0-6m/min | |

| Forming speed: | 0-6m/min | |

| Forming step: | 22 | * According to your profiles |

| Decoiler: | Manual decoiler | 1.5ton |

| Main motor: | 5.5kw | |

| Transmission system: | Chain | |

| Machine structure: | Cast iron support | |

| Shaft material: | 40Cr | |

| Shaft diameter: | φ70mm | |

| Roller material: | GCr15, HRC58-62° | |

| Cutting system: | Flying hydraulic cut and punch | |

| Servo motor power: | 3kw | Delta Brand |

| Hydraulic motor power: | 4kw | |

| Size change method: | Manual spacer adjustment | |

| Encoder: | Omron Brand | |

| Inverter: | Delta Brand | |

| PLC: | Delta Brand | * Siemens (opcional) |

| HMI: | Delta Brand | * Siemens (Opcional) |

| Language: | English | |

| Electricity : | 220V 60Hz | * 440V 60Hz |

| Machine color: | White | * Or according to your requirements |

| Delivery: | 90 Days | |

| Container: | 1*20GP | |

| Total weight: | 5ton | |

| Dimensions: | 18m*1.3m*1.5m | |

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)