Cassette Type Octagonal Tube Roll Forming Machine

.jpeg)

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)

.jpeg?x-oss-process=image/resize,w_100/quality,q_100)

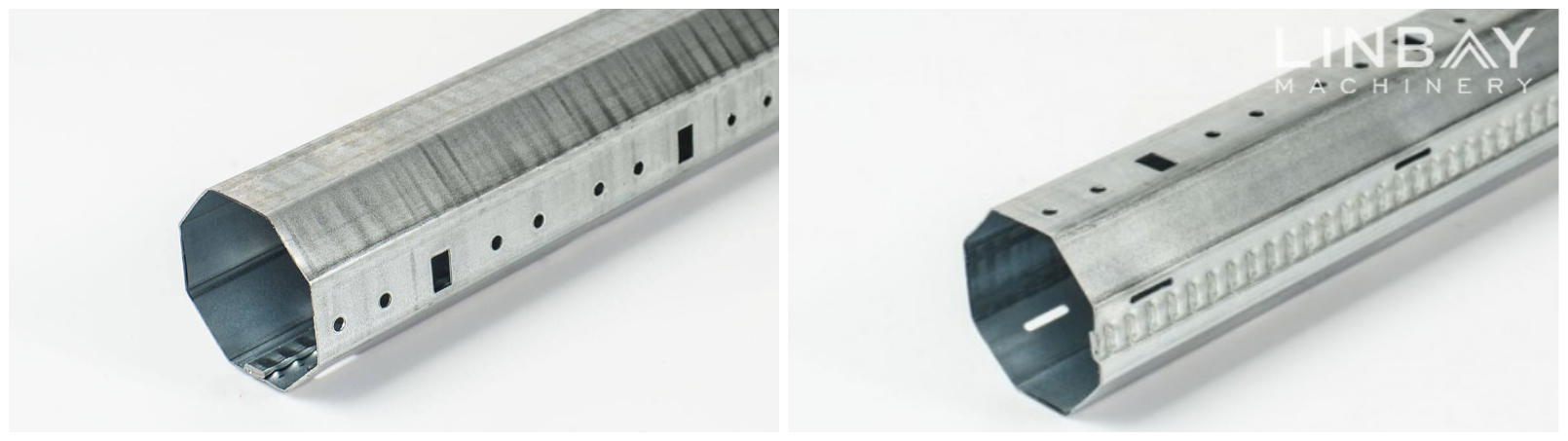

Profile

The octagonal tube is a very important accessory in the rolling shutter system. During the forming process, the steel coils will be connected and overlapped on one side by roll forming machine, so that the profile becomes a closed regular octagonal shape.

Usually, octagonal tubes are produced from galvanized steel. In the market, the following three sizes have gained prominence:

| Thickenss | Diameter | Feed width |

| 0.5-0.6mm | 40mm | 143mm |

| 0.6-0.8mm | 60mm | 210mm |

| 1-1.2mm | 70mm | 248mm |

In addition to the three sizes, we can also produce other sizes. Before we design the roll forming line, we will communicate with customers on the size and materials to ensure more accurate quotations.

Flow chart:

Decoiler-Servo feeder-Punch press-Roll forming machine-Flying saw cut-Out table

Decoiler

The hydraulic decoiler is powered by the hydraulic station, so that the steel coil is uncoiled and gradually enters the machines. It can save labor cost. The width of the steel coil varies with the size of the octagonal tube, so the corresponding steel coil needs to be replaced when changing the size. According to customer's budget and requirement, we can also provide manual decoiler.

Servo feeder

The servo feeder is powered by a servo motor, compared with the regular motor, it can make the feeder have almost no start and stop time, which can make the production process more efficient and smooth.

There is an encoder device in the servo feeder, which can convert the length of steel coil into an electrical signal, so that the feeder can more accurately control the distance that the steel coil advances, and finally achieve precise punching. At the same time, there is a pipeline connected to the air compressor to pneumatically lead the steel coil, which can be more efficient and accurate, and the operation and maintenance are relatively simple.

Then, the steel coil is sent to the punch press for punching holes.

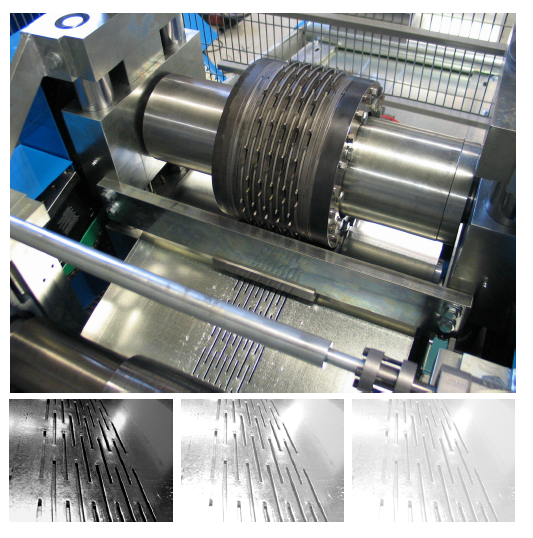

Punch press

The punching force of this punch press is 25 tons, and it can work quickly, continuously and regularly. There is a PLC control cabinet that can control the work of the punch press, with multi-language versions, simple and easy to operate.

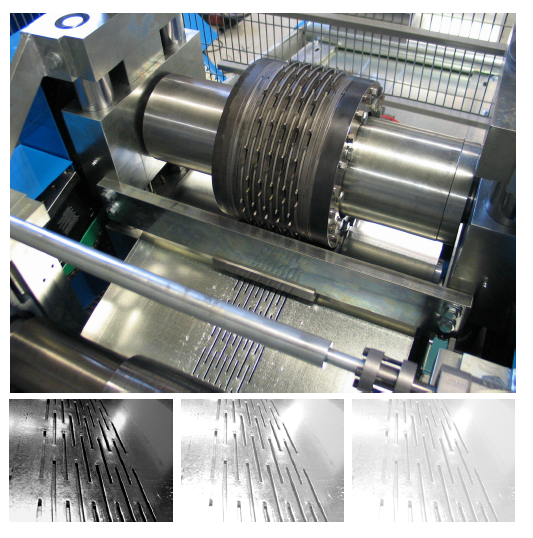

Punch mold

Except for the side with the interface, the other seven sides can be punched. The punching position, hole type and size can be customized according to customer needs.

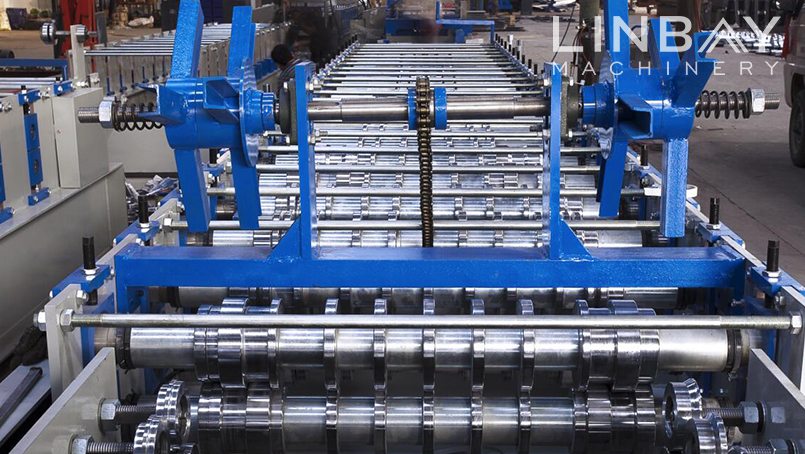

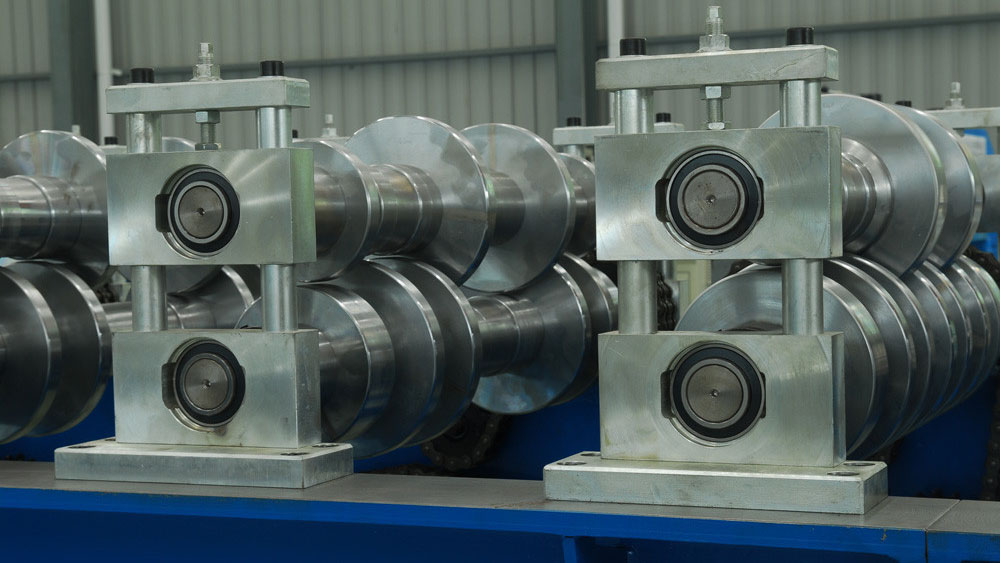

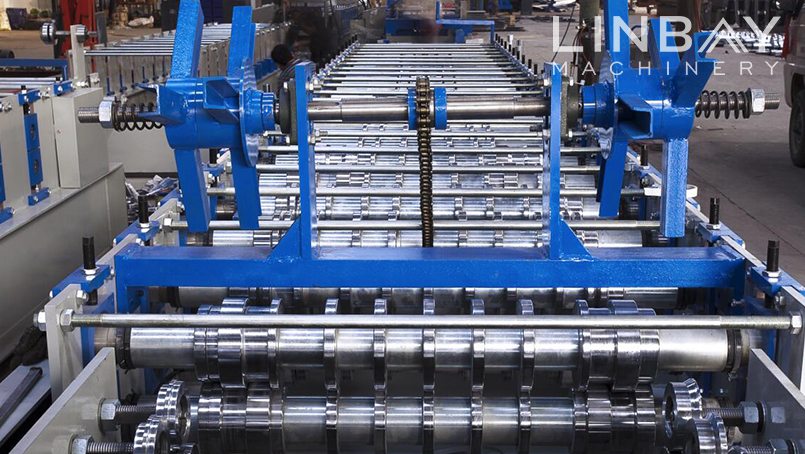

Roll former

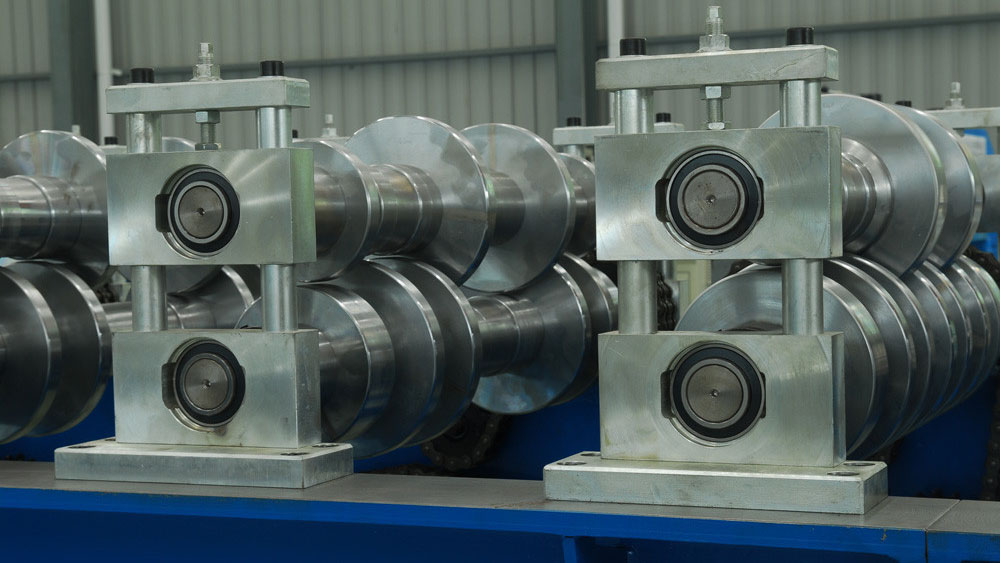

Normally we recommend our customers that one roll forming machine produce one size of octagonal tube, but we have innovated a cassette type octagonal tube roll forming machine that multi-size production can be realized by changing the forming stations by using the same roll former base.

Saw cut

The octagonal tube finally comes to the cutting machine. Because the octagonal tube is a closed shape, in order to avoid the bending of the cut-out due to the use of hydraulic cutter, we use saw cutter. In addition, this flying saw cutter does not stop to wait for the octagonal tube to be delivered after the cutting, but works continuously, which greatly improves the automation and efficiency of the entire line.

Finally, the cut octagonal tubes come to the out table. There is an encoder in the forming machine to record the working length of the steel coil, which enables machine to precisely control the cutting length error within ±0.5mm. And through the PLC control cabinet, we only need to input the desired cutting length on the screen to cut accurately.

Technical specification

|

Steel Strut& Rail roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):1.5-2.5 |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

10-20 |

Or according to your requirement |

|

3 |

Forming station |

17 |

According to your profile |

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

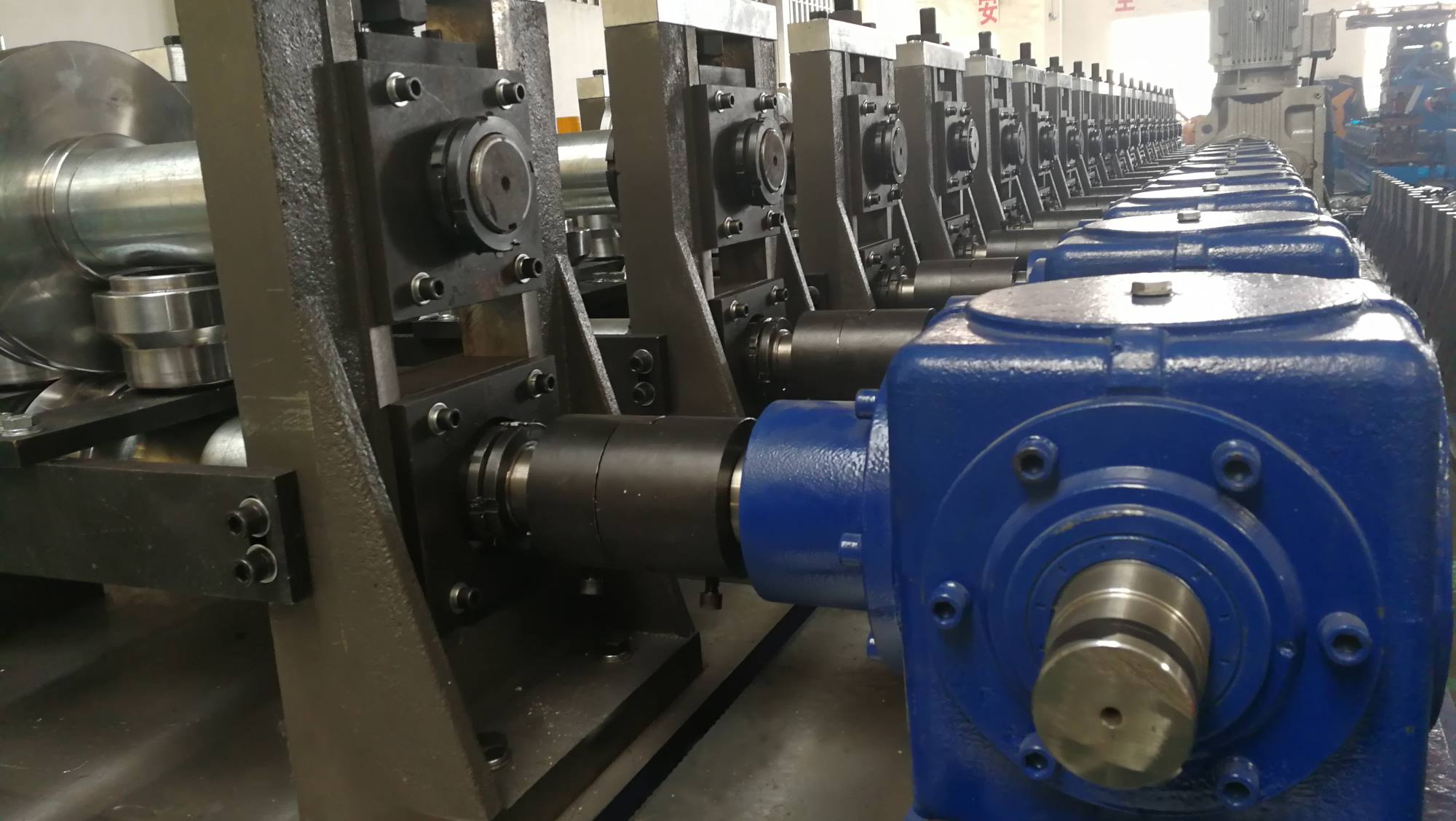

Driving system |

Gearbox drive |

Chain drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Torri stand structure |

Forged Iron station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

More Pictures

-

Others

-

scrap collector

-

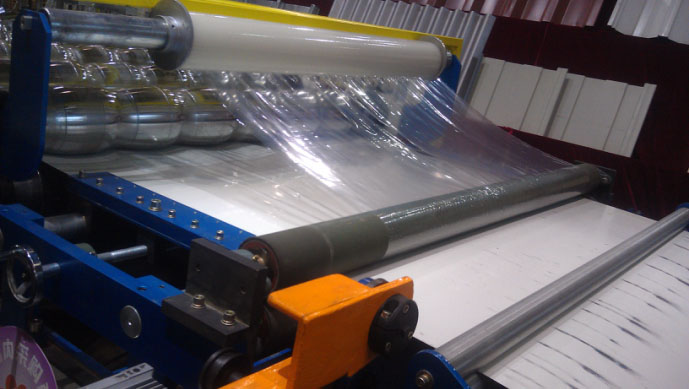

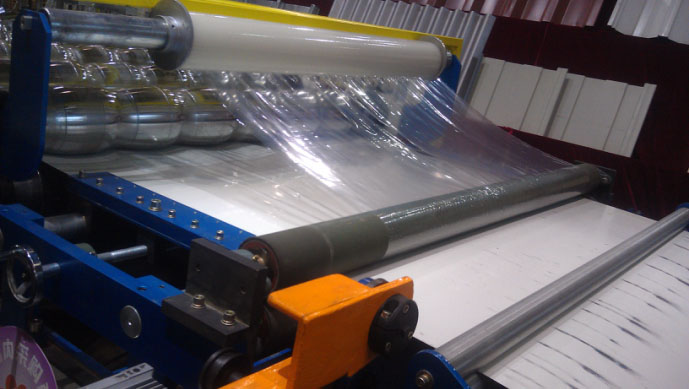

pasting

-

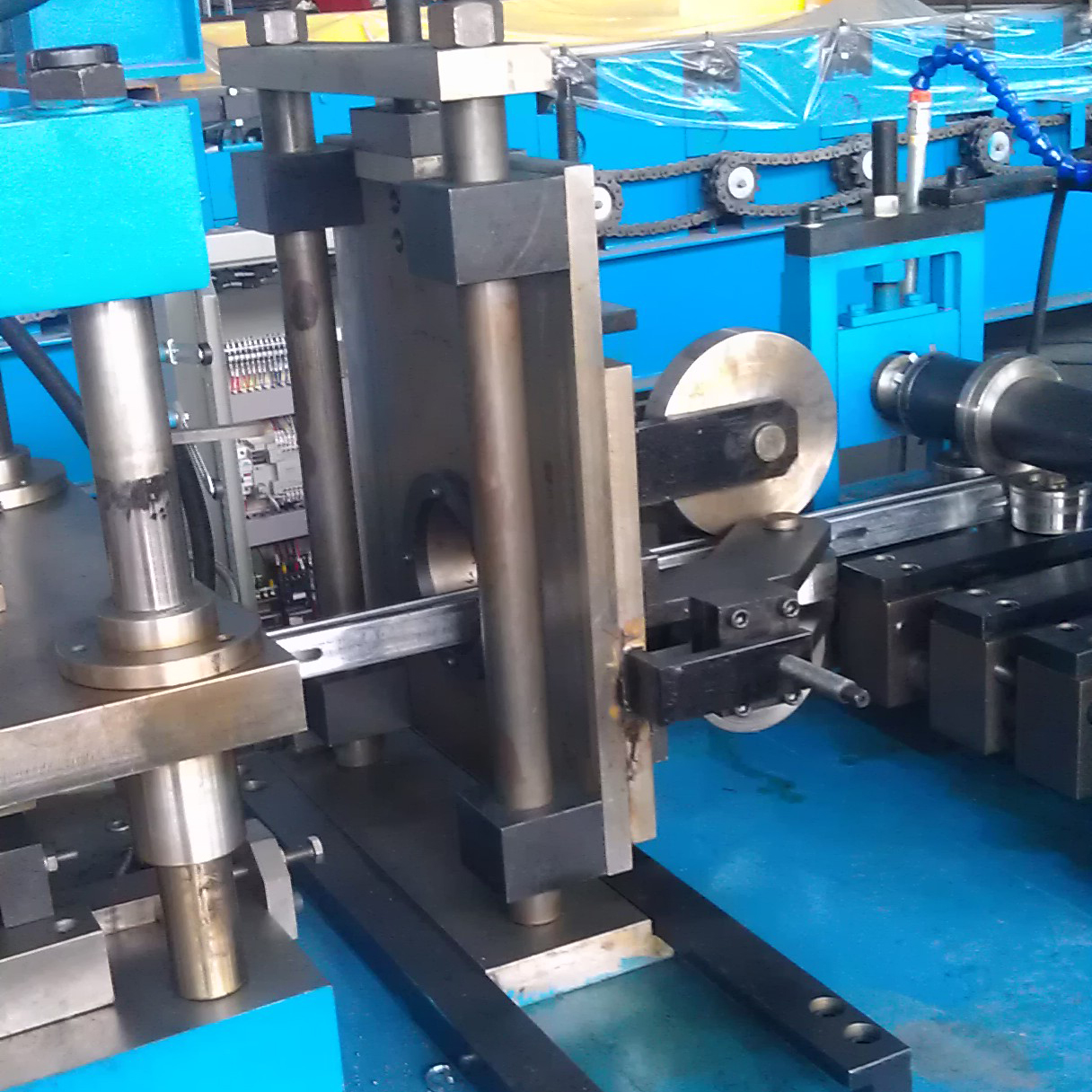

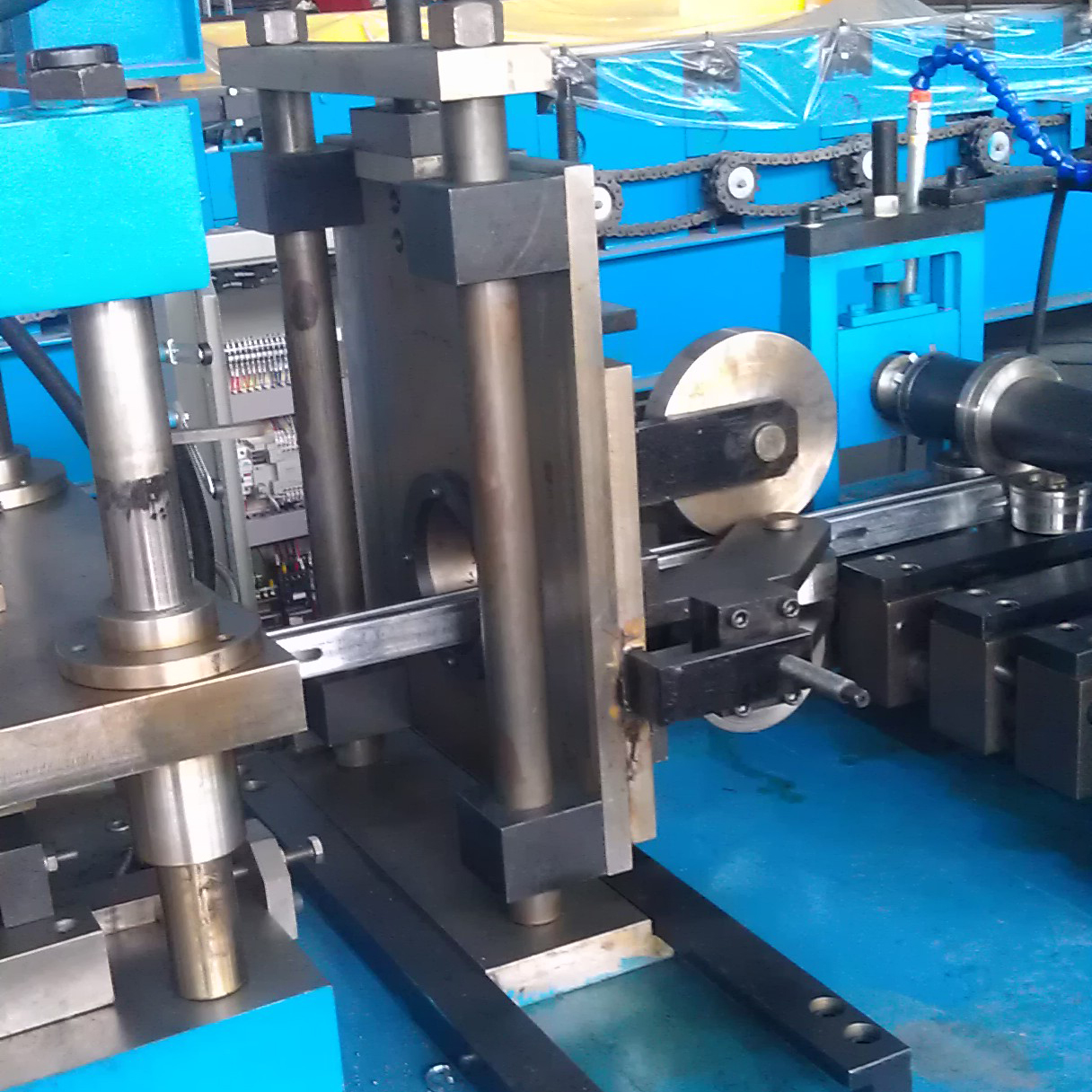

mould change

-

guiding head

-

Cooling system

-

-

Out table

-

non-powered

-

auto stacker

-

-

Cutting

-

saw cutting

-

flying shear

-

-

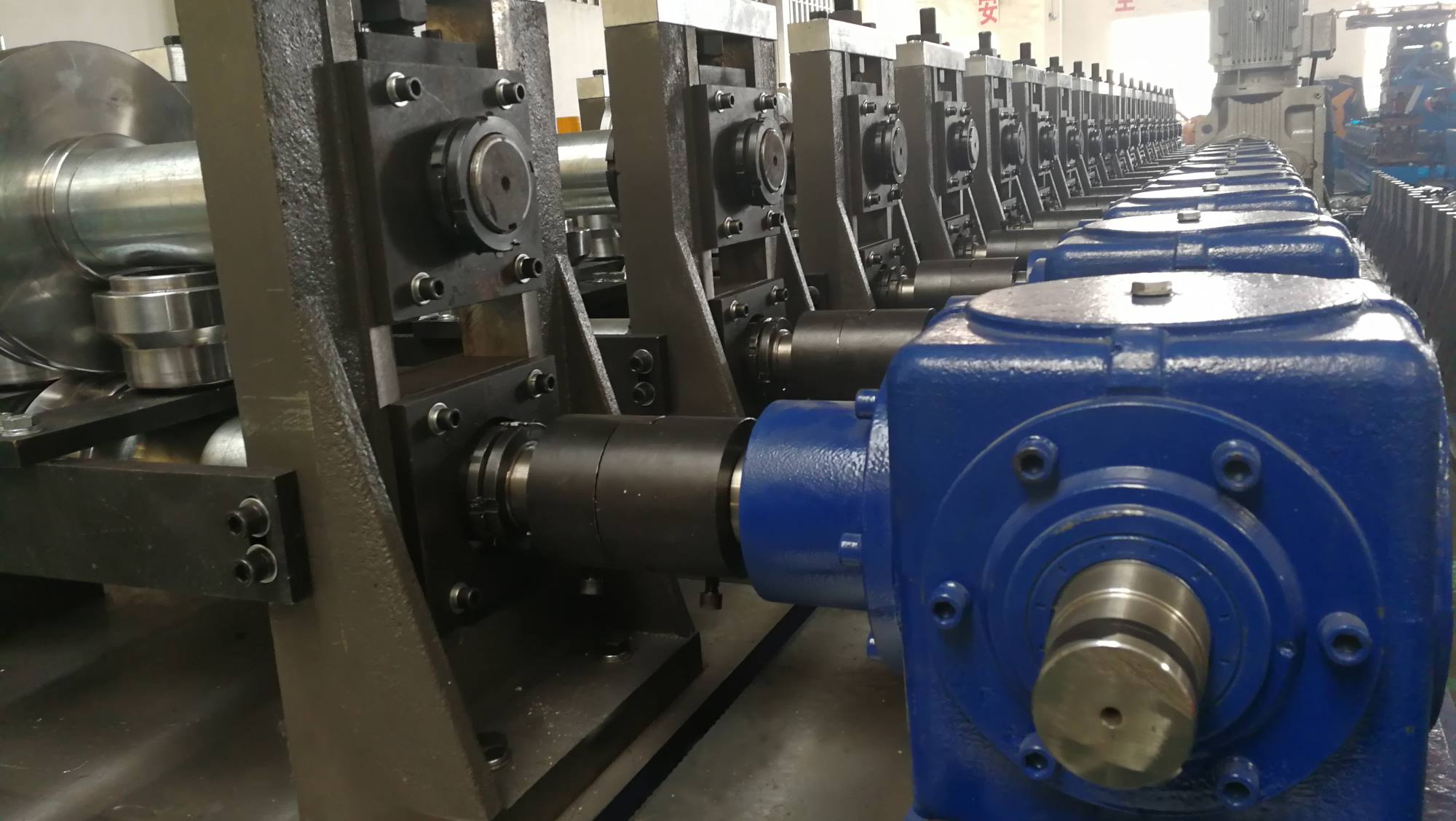

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for Cpurlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-