Metal fencing is a modern fencing material that at first glance looks like the familiar wooden fence, but at the same time it has a more aesthetic appearance and does not require meticulous maintenance. The variety of coatings and the presence of a wide range of colors will help you to realize your plans. For soft shapes lovers, we recommend the upper oval cut. Of course it can also be cut directly to a horizontal fence.

This type of fence post is mostly popular in European countries, such as Russia, Ukraine, Lithuania, etc. So it can be called Eurostudent/ Europlank as well. Most of them are made of galvanized steel, usually 0.4-0.5mm thick, and then coated with polymer coatings.

Eurostudent (or metal fence, europlank) is a profiled strip made of galvanized steel with a polymer coating. By design, a eurostudent fence is the same fence as a wooden fence, the only difference being that here the fence is metal.

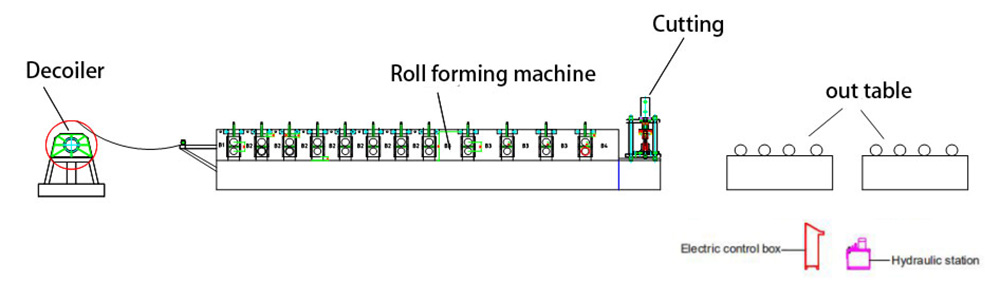

European fences are produced by loading narrow strips of steel into a roll forming machine, passing them through forming rollers to obtain reinforcements and shapes, and then cutting them to a certain length (the length required by the customer). This production technique is similar to the production of roof panels in many respects , differing only in the end cut.

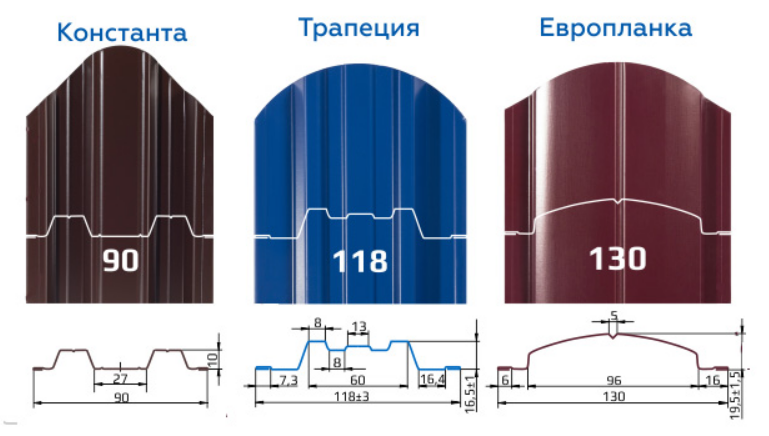

(By Profile type: M, P, C profiles, "Constant", "Trapeze", "Europlank")

The complete forming process for metal fence posts: uncoiler - forming machine - shearing -out tables. Very simple and clear, the focus is on the final mould shearing part where we add a mould so that the shear comes out rounded.

There are roughly three types of shear shapes on the market, and it is only necessary to make shear moulds according to customer requirements. Our machines are more aesthetically pleasing in shape without deformation when punching and shearing.

We can also make double or triple row forming machines depending on the number of customer profiles, which can be more cost effective and offers a more diverse range of products. Our machines do not cause any visible damage to the surface. If the customer demands, a laminating device can be installed at the inlet to completely protect the surface of the profile.

We also have other related post profile machines:

Related products: Vineyard Post Roll Forming Machine

This production line working speed is around 12-15m/min according to cutting length, the forming speed is around 0-20m/min adjustable.

3 Ton Manual decoiler--Roll former--Hydraulic cut--Out tables

|

Metal Fence Post Roll Forming Machine |

|||

|

NO. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Cold-rolled steel, Galvanized steel, PPGI, stainless steel |

|

|

Thickness(mm):0.4-0.5mm |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensile stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

12-15m/min |

Or according to your requirement |

|

3 |

Forming station |

12 |

According to your profile |

|

4 |

No. of rows in the forming section |

Double row structure |

Three or according to your profile |

|

5 |

Decoiler |

3Ton manual decoiler |

3 ton hydraulic decoiler |

|

6 |

Main machine motor |

7.5 kw Sino-German Brand |

Siemens |

|

7 |

PLC brand |

Panasonic brand |

Siemens/Delta |

|

8 |

Inverter brand |

Yaskawa brand |

Delta |

|

9 |

Driving system |

Chain drive |

Gear box drive |

|

10 |

Rollers’ materail |

#45 steel |

Cr12Mov/GCr15 |

|

11 |

Station structure |

Wall panel |

Iron cast structure |

|

12 |

Cutting system |

Post-cutting |

/ |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

|

15 |

Contactor |

Schneider brand |

Or according to your requirement |

1. Q: What kinds of experience do you have in producing bracing roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, Step beam roll forming machine and Shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2. Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. For upright rack beam, our customer usually make 3-4 sizes in one machine. We would check your profile drawings to meet your needs. In this way, we will greatly reduce your cost and time.

3.Q: What is delivery time of your bracing roll forming machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory-self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.