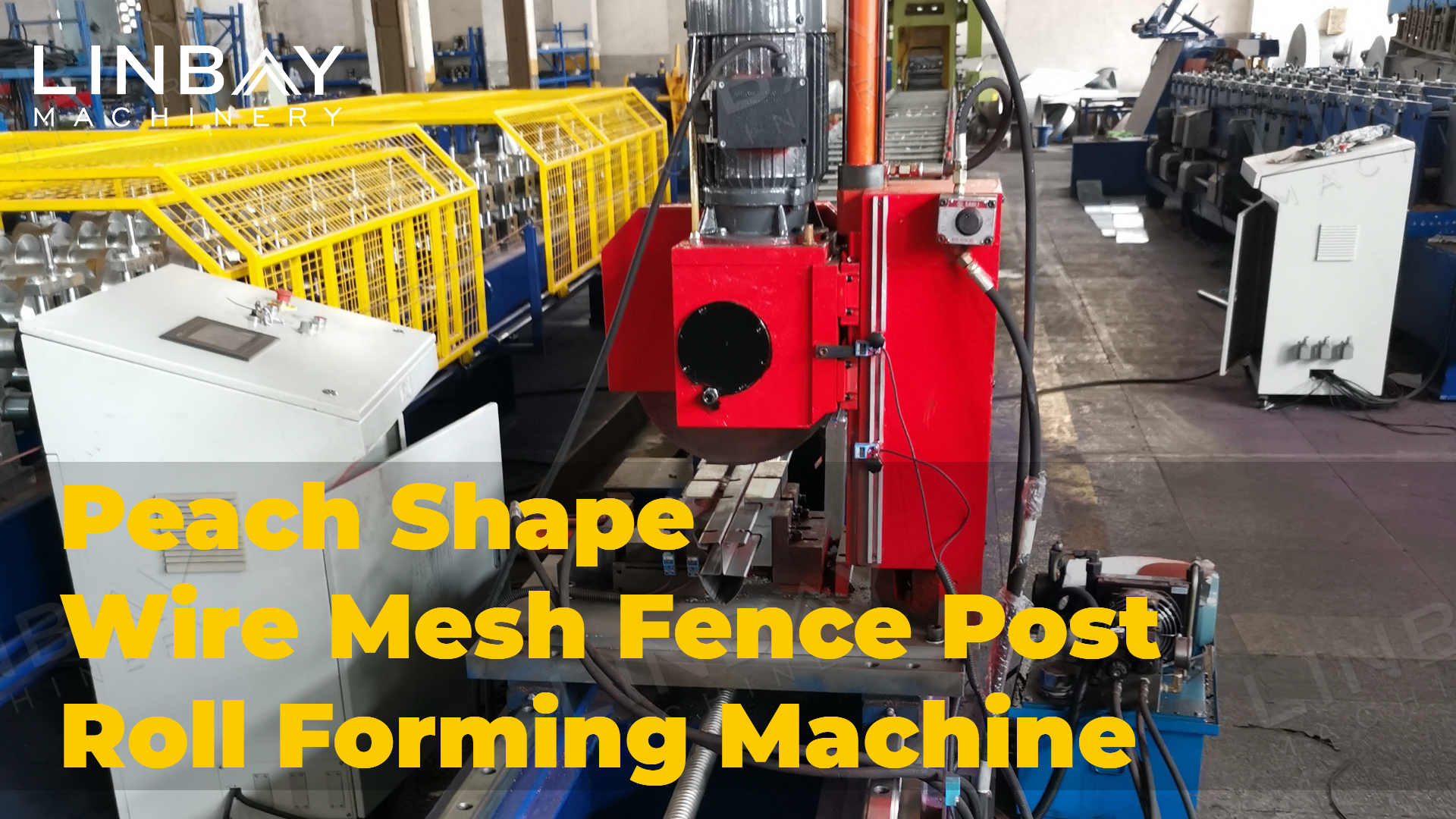

Peach Shape Wire Mesh Fence Post Roll Forming Machine

Profile

This wire mesh fence post, also known as peach post, derives its name from its outer shape resembling that of a peach. Typically crafted from low-carbon or hot-rolled steel coils, the peach post undergoes cold rolling to form its distinctive shape.

The edges of the steel coil are bent outward to create a U-shaped hook, enhancing the stability when securing the wire mesh. Notch slots are strategically placed on both sides of the peach post for installing the metal wire mesh, with the slot dimensions tailored to fit the mesh size.

The complete production line includes notch punching and roll forming. The forming rollers and punch dies are customized to ensure precise shaping and notch placement.

Real case-Main Technical Parameters

Flow chart

Hydraulic decoiler-Leveler-Servo feeder-Punch press-Pit-Roll former-Flying saw cut-Out table

Main Technical Parameters

- Line speed: 0-6 m/min, adjustable

- Profiles: One size of mesh fence post

- Material thickness: 0.8-1.2mm (in this case)

- Suitable material:Hot rolled steel, cold rolled steel

- Roll forming machine: Wall-panel structure and chain driving system.

- Of forming station: 26

- Riveting system: Roller type, roll former doesn’t stop when riveting.

- Cutting system: Saw cutting, roll former doesn’t stop when cutting.

- PLC cabinet: Siemens system.

Real case-Description

Hydraulic decoiler

The decoiler offers versatility in manual, electric, and hydraulic options. Choose the suitable type based on coil weight and thickness to ensure seamless uncoiling.

With a robust loading capacity of 5 tons, this hydraulic decoiler is equipped with outward coil retainers to prevent the slippage. The motor powers the expansion device, facilitating expansion and contraction to accommodate various coil inner diameters ranging from 460mm to 520mm.

Leveler

The leveler efficiently flattens the coil, relieving internal pressure for improved punching and forming processes.

Servo feeder & Punch press

Our servo feeder, boasting minimal start-stop delays, provide precise control over the feeder, ensuring accurate coil feed length and punch positions.

Finished wire mesh fence posts feature numerous notches for wire mesh connections.

Roll forming machine

This roll forming machine has a wall-panel structure and a chain drive system. During the forming process, the coil gradually deforms under force, conforming to the specified "Peach shape" as per the provided drawings.

To prevent coil separation at the post junction during extended use, precautionary measures are implemented. After roll forming, riveting rollers press the coil overlap, making rivet impressions that enhance post stability and lifespan.

Furthermore, owing to the circular design of the riveting rollers, the roll former can seamlessly continue its operation as the coil advances during riveting without setting another moving base for riveting device.

Flying saw cut

Given the enclosed shape of the peach post, saw cutting emerges as the most suitable method, preventing any coil deformation at the cut edges. The cutting process does not produce waste. To enhance production line capacity, the cutting machine's base can be adjusted backward and forward to match the roll forming machine's speed, ensuring uninterrupted operation.

Introduction:

This wire mesh fence post roll forming machine has a basic configuration: manual decoiler-hydraulic chamfer-roll former-hydraulic punch-hydraulic post cut-out table. At the feeding part of the roll forming machine, we make a chamfer device, this is easy for post cutting. The punch system equipped on the roll former, it can reduce the machine’s cost it’s an economic choice, but the working speed will be low, around 4m/min. Customer can choose Case B’s machine configuration if you want a fast speed roll forming machine.

Introduction:

This wire mesh fence post roll forming machine has a high speed and precision configuration: manual decoiler- leveler-servo feeder-punch press- roll former-flying saw cut-out table. The servo feeder system uses Yaskawa servo motor to control the feeding length for the punch press, then you will have a high-precision at the holes punch part. The 80Tons press can offer a fast punch speed compared hydraulic punch system, it can double the production, up to 8m/min. Normally we suggest our customer buy Yangli brand press JH21-80. The roll former part we use 26 forming stations to ensure the profile prefect and 2 riveting rollers to make profile together. With this fast speed, we put a flying saw cut device, which will not stop the roll former when cutting. The saw cut has a smaller burr and wastage(around 3mm). This is the best roll forming machine solution we suggest for wire mesh fence post.

Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Whole Production Line of Wire Mesh Fence Post Roll Forming Machine

| Metal Fence Post Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.7-1.3, 3mm |

| B) Black steel | ||

| C) Carbon steel | ||

| Yield strength : | ≤350 Mpa | |

| Tensil stress : | ≤350 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press 80Tons (Optional) |

| Forming station : | 26 | |

| Mian machine motor power: | 2*11KW | |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens Beide (Optional) |

| Driving system : | Chain drive | |

| Machine structure: | Wall panel type | * Forged Iron station (Optional) |

| Working speed : | 4 (M/MIN) | * 6-8m/min (Optional) |

| Rollers’ material : | 45 steel | * GCr15 (Optional) |

| Cutting system : | Post hydraulic cutting | * Flying saw cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

1. Q: What kinds of experience do you have in producing wire mesh fence post roll forming machine?

A: We have exported wire mesh fence post production line to Algeria, Russia and Indonesia. The metal fence post has a Z shape profile, which is very common profile drawing, and we have exported thousands of Z profile roll forming machines.

2. Q: What is delivery time of wire mesh fence post roll forming machine?

A: 60 days normally.

3. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Now we have made two different machines, which is faster with punch press, its speed is 8m/min, and the other more economic one has speed around 4m/min.

4. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

5. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

-

Out table

-

Non-powered

-

Auto-stacker

-

-

Cutting

-

Saw cutting

-

fast flyting cutting

-

-

Driving

-

chain driving system

-

gearbox driving system

-

Gearbox with couplings

-

-

Stands

-

Torri Stands

-

Forged Iron Stands

-

Wall Panel

-

ruler

-

-

Punching

-

Hydraulic punching station

-

Fast Roller Punching system

-

Punching press

-

-

Feeding

-

Servo feeder

-

Leveler

-

-

Decoiler

-

Motorized&Hydraulic decoiler

-

Double head motorized decoiler

-

Manual Decoiler

-