Automatic Trellis U-Channel Post Roll Forming Machine

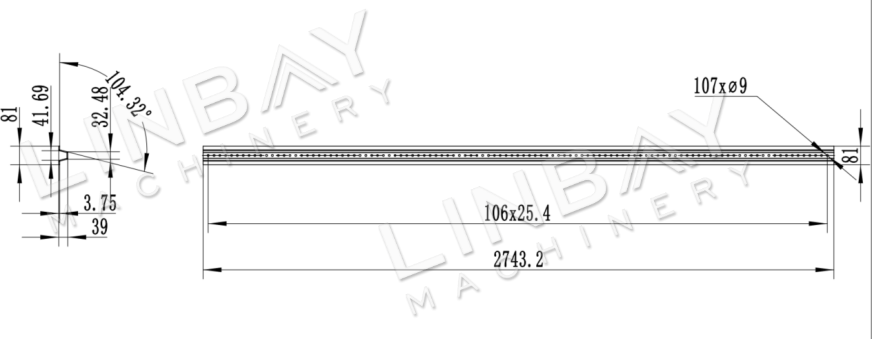

The Trellis U-channel post is a hat-shaped fence post, widely applied in the agricultural sector, such as for grape trellises, apple frames, etc.. It has a top width of 32.48mm, a bottom width of 41.69mm, and a total width of 81mm, with a height of 39mm. Each post is 2473.2mm long and features 107 closely spaced, continuous 9mm diameter holes, facilitating flexible installation of various-sized brackets.

Decoiler with leveler--Servo feeder--Punch press--Roll former--Flying cut--Out table

Decoiler with Leveler

This machine integrates the functions of decoiling and leveling. The decoiler is equipped with a brake device to adjust the tension of the decoiling roller and control the smoothness of the decoiling process. Additionally, steel protection leaves are installed to prevent the steel coil from slipping during decoiling. This design makes it a cost-effective and high-safety decoiler, helping save the floor space for the production line.

Next, the steel coil enters the leveling machine. Due to the thickness of the steel coil (2.7-3.2mm) and the presence of dense punching, it is essential to use a leveler to eliminate the curvature of the steel coil, thereby improving its flatness and parallelism. The leveling machine is equipped with 3 upper leveling rollers and 4 lower leveling rollers.

Servo Feeder & Punch Press

In this case, a 110-ton punching press from the Yangli brand, along with a servo feeder utilized. The servo motor ensures rapid response with virtually no start-stop time waste, allowing precise position control. Yangli brand with offices worldwide, ensures high-quality after-sales service. Customized molds are created based on customer-provided punching drawings, efficiently punching 9mm diameter holes. The punching dies are made of SKD-11 steel for high wear resistance and hardness.

In the PLC control program, we simplify the input of punching data by controlling the quantity of punching holes. Additionally, there is a commonly used parameter memory function, allowing customers to store 10 sets of punching parameters according to production needs. These parameters can be easily recalled and used without the need for re-input.

Limiter

A limiter is placed between the punching and roll forming parts to coordinate production speed. When the steel coil touches the lower limiter, indicating a punching speed greater than the roll forming speed, the punching machine receives a signal to stop working. A prompt sign appears on the PLC screen, requiring the operator to click on the screen to resume work.

Conversely, when the steel coil touches the upper limiter, indicating a roll forming speed greater than the punching speed, the roll forming machine stops working. During the seconds it takes for the roll forming machine to resume work, the punching machine continues its operation.

This setup ensures overall coordination and uniformity of production speed on the production line.

Guiding

Before entering the first set of forming rollers, the steel coil is guided through a guiding part using the guiding rollers to keep the coil and machine on the same centerline, preventing distortion of the formed profiles. Guiding rollers are strategically placed throughout the entire forming line. Measurements of each guiding roller to the edge are recorded in the manual, allowing easy repositioning if slight displacement occurs during transportation or production adjustments.

Roll Forming Machine

The roll forming machine, the most crucial part of the entire production line, consists of 10 forming stations with a cast-iron structure and gearbox driving system. The forming speed can reach 15m/min. The forming rollers are made of Cr12 high-carbon chromium-bearing steel for excellent hardness and wear resistance. The rollers are chrome-plated to extend their lifespan, and the shafts are made of 40Cr material.

Flying Laser Coder (Optional)

Before cutting, a laser coder is optionally installed, moving at the same speed as the cutting machine without affecting the continuous operation of the roll forming machine. This highly automated system features a touchscreen interface, induction eyes, and a lifting bracket. It enables laser printing of text, graphics, QR codes, etc., facilitating product standardization, production control, and brand promotion.

Flying Hydraulic Cutting & Encoder

A Japanese Koyo encoder in the forming machine converts sensed steel coil length into an electrical signal sent to the PLC control cabinet. This enables precise control of cutting errors within 1mm, ensuring high-quality products and minimizing waste. The cutting molds are shaped to match the profile, ensuring burr-free cuts without deformation. The "flying" means the cutting machine can move in tandem with the roll forming speed, maintaining continuous operation and enhancing overall production efficiency.

Hydraulic Station

The hydraulic station features built-in cooling fans to efficiently dissipate heat, enhancing continuous operation and durability. The hydraulic station has a low failure rate and is designed for long-lasting use.

PLC control cabinet

Operators can control production speed, set production dimensions, cutting lengths, etc., through the PLC screen. The PLC control cabinet includes protection functions such as overload, short circuit, and phase loss. The language displayed on the PLC screen can be customized based on customer preferences.

Warranty

The production line is provided with a two-year warranty from the delivery date, indicated on the nameplate. The rollers and shafts receive a five-year warranty.

|

Metal Trellis Post Roll Forming Machine |

|||

|

NO. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Cold-rolled steel, Galvanized steel, PPGI, stainless steel |

|

|

Thickness(mm):0.4-0.5mm |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensile stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

12-15m/min |

Or according to your requirement |

|

3 |

Forming station |

12 |

According to your profile |

|

4 |

No. of rows in the forming section |

Double row structure |

Three or according to your profile |

|

5 |

Decoiler |

3Ton manual decoiler |

3 ton hydraulic decoiler |

|

6 |

Main machine motor |

7.5 kw Sino-German Brand |

Siemens |

|

7 |

PLC brand |

Panasonic brand |

Siemens/Delta |

|

8 |

Inverter brand |

Yaskawa brand |

Delta |

|

9 |

Driving system |

Chain drive |

Gear box drive |

|

10 |

Rollers’ materail |

#45 steel |

Cr12Mov/GCr15 |

|

11 |

Station structure |

Wall panel |

Iron cast structure |

|

12 |

Cutting system |

Post-cutting |

/ |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

|

15 |

Contactor |

Schneider brand |

Or according to your requirement |

1. Q: What kinds of experience do you have in producing bracing roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, Step beam roll forming machine and Shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2. Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. For upright rack beam, our customer usually make 3-4 sizes in one machine. We would check your profile drawings to meet your needs. In this way, we will greatly reduce your cost and time.

3.Q: What is delivery time of your bracing roll forming machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory-self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.