CZ Sigma Purlin Roll Forming Machine

09 May

This fully automatic CZ roll forming machine is produced by Linbay Machinery. The working thickness range is 1.5mm-3.5mm(gearbox drive), width range is 80-300mm, height range is 40-80mm. With one machine you can make multisizes product. It's a practical and economic machine in steel frame industry.

Now in China there are 3 types of C/Z purlin quick changeable machine in market from profile C to profile Z. The oldest generation is you need to manually swift 18 forming rollers, the secound generation is you only need to swift 4 forming stations, the newest one is automatically swift rollers by motor. Linbay offers the secound generation and newest CZ purlin roll forming machine.

In this video this machine has newest technology that no need to manually switch between C profile and Z proflie, it can be converted directly by motor on the control cabinet through the touch screen. Similarly, the width, height, and length of the lip can be adjusted on the control cabinet. Multiple servo motors on the forming machine can ensure accuracy and efficiency.

The cutting part uses tracking universal shears. This cutting method can be adjusted according to the size of profile, all sizes only need one set of cut. Shearing and forming are carried out simultaneously without downtime, maximizing production efficiency.

Besides, in this machine base if we add 4 forming stations, we could make one more profile: sigma profile.

Hello everyone, this is a CZ purlin roll forming machine, this video shows the production process.

Decoiler--fedding--roll forming--hydraulic cut--Out table

The post universal cut is used for all sizes and C and Z shape. It's an all-purpose cutting type.

The standard size that this machine produce is:

Width:80-300mm

Height:40-80mm

Thickness: 1.5-3mm

You can produce any size in this range.

This C/U purlin roll forming machine with flying punch and shear is manufactured by Linbay Machinery for South American customer.

There have hydraulic shear after the leveller to cut off the head and tail of the material.

This line is capable of producing C/U purlins of 2-4mm thickness.

Each forming station is of cast iron construction, ensuring the high strength stability of the machine.

Because it uses a flying punching and shearing system, it can produce 10-30m per minute, which is more than twice as fast as the traditional stop shear-and-punch method.

This solution is ideal for customers with high capacity requirements.

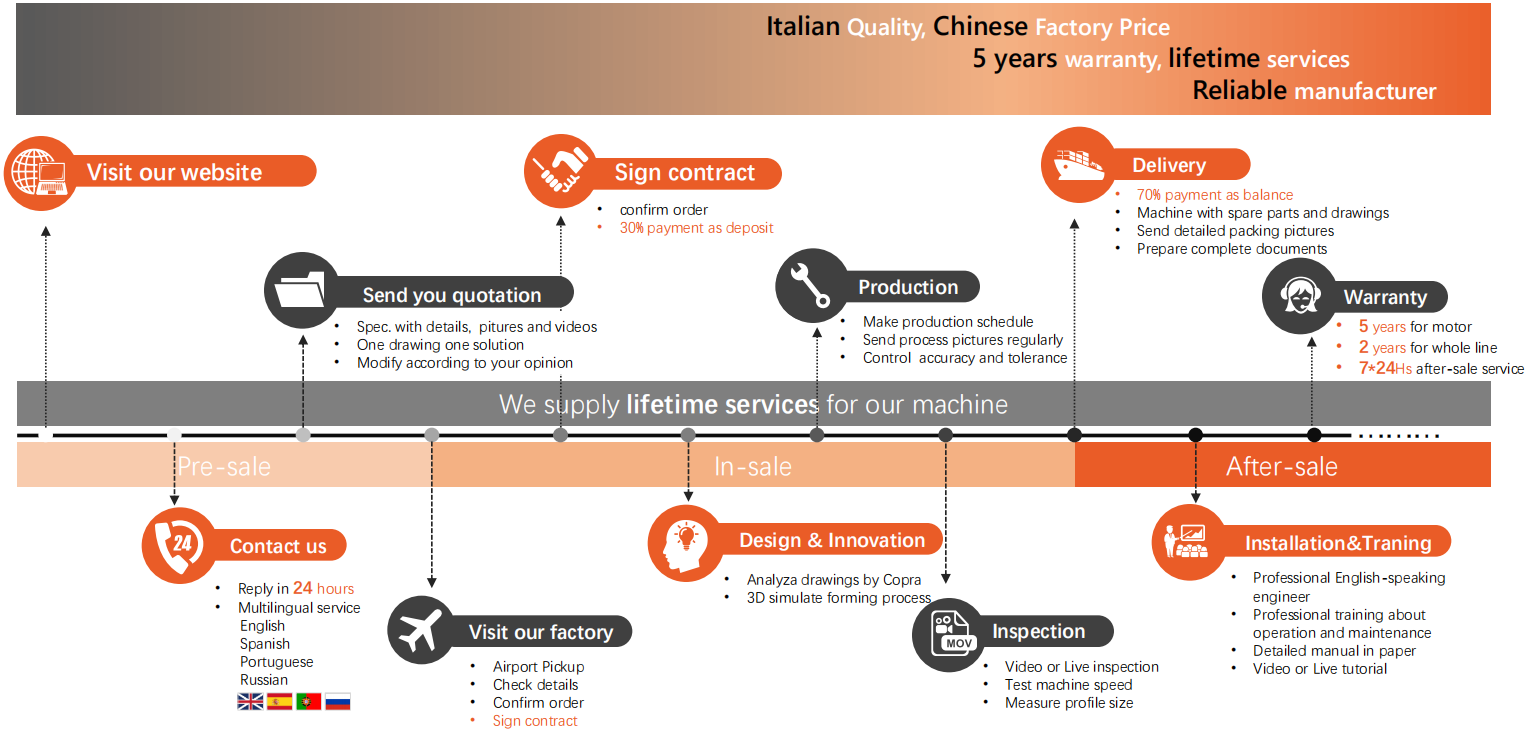

To cope with the difficulty of getting engineers out of the country due to the COVID-19, every Linbay machine exported comes with a video installation manual and instruction manual, and English-speaking engineers are available to assist customers remotely with the installation and use of the machine.

Control screen language can be customised, English, Spanish, Russian etc.

The operator interface is logical and easy to change parameters.

Please feel free to contact Linbay with any questions or requests regarding the roll forming machine.

This is C Z Sigma Profile Purlin Roll Forming Machine, which is manufactured by Linbay Machinery.

There are three hydraulic cylinders to control the punching.

The die on each station can be replaced, and each set can be replaced in 5 minutes, the operation is simple. We have video tutorial to teach you how to change.

This design ensures the diversity of products produced by customers.

When the Koyo encoder measures the length to the cutting position, the pre-cutting is completed.

Each forming station is made by iron cast to ensure the high strength and stability of roll former.

The production line integrates levelers, hydraulic punches, front shear and roll forming machine to maximize economics while ensuring functionality.

This is a typical C/Z purlin roll forming machine, driven by chain. Automatically change profile sizes by input size datas at touch screen.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor