Cable Tray Roll Forming Machine

07 May

This is a fully automatic perforated cable tray roll forming machine, exported by Linbay Machinery to Argentine.

This production line can produce perforated cable tray and its corresponding cover with a thickness range of 0.8-1.5mm and a width range of 100-600mm.The cable tray of this structure has good heat dissipation, and can effectively protect the cable from being scratched when laying the cable over a long distance. All rollers on the roll forming machine are made of Cr12 material and use chrome plating technology, which can effectively protect the surface of the cable tray from being scratched.

This is the double-row cable ladder roll forming machine manufactured by Linbay for our Southeast Asian customers.

This line can produce side wall and rung of cable ladder.

This machine is recommended for customers with low production volumes and is very cost effective.

The use of servo feeder prior to the hydraulic punching machine allows the punching of holes with a high degree of accuracy compared to conventional encoder.

The forming machine uses the gearbox drive method, which makes the power output more stable and reliable, as well as fast.

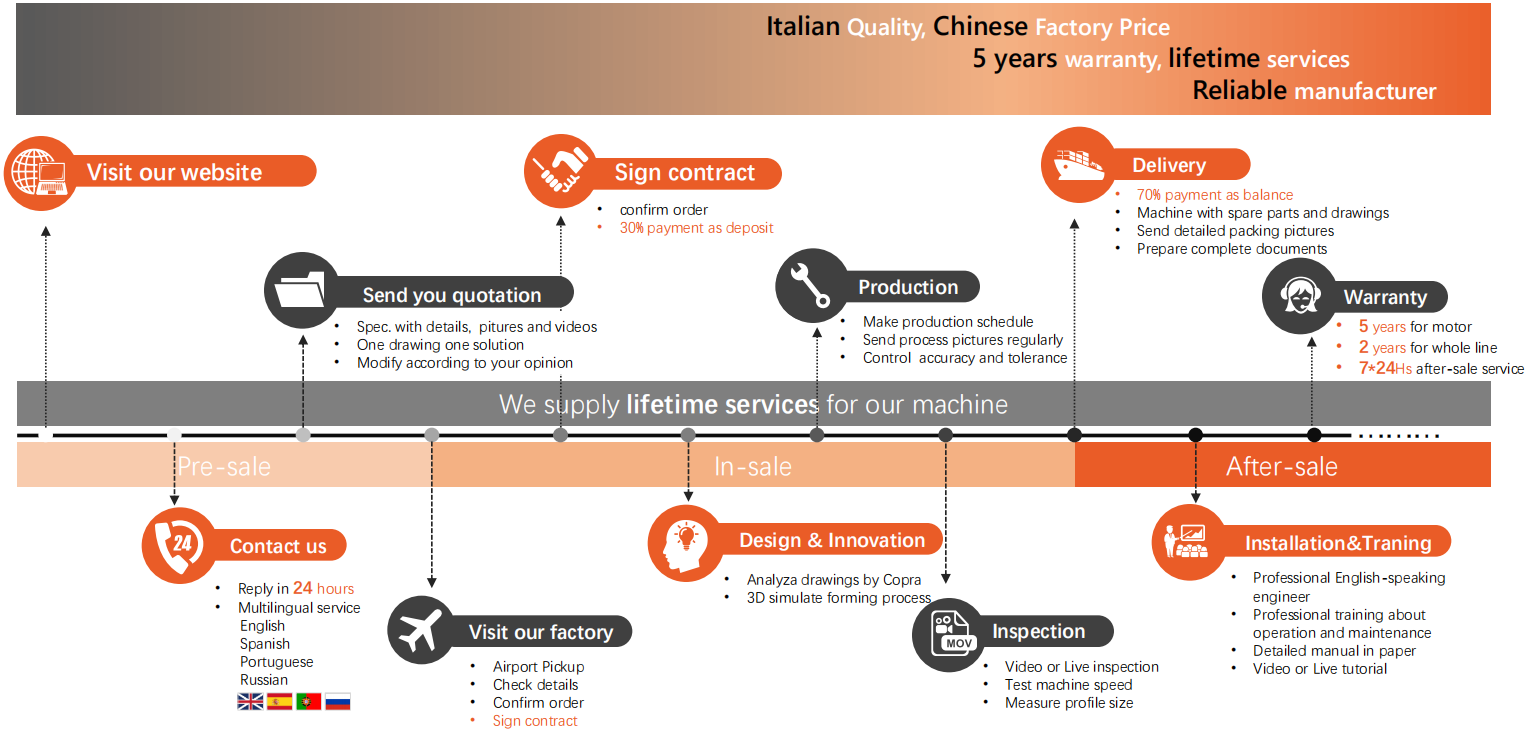

In order to solve the problem of the inconvenience of traveling abroad to install the machine, we will make a customized video installation tutorial and a written guide for each of our customers, as well as a remote guide for our English-speaking engineers to install and use the machine. To date, we have had dozens of successful remote installations.

Shear method is hydraulic tracking shear, no downtime required.

Delivery date: 120 working days

Warranty: 2 years

Hello everyone, this is Lydia from LINBAY MACHIENRY, this is a installation video for strut channel machine, this video shows to customer how to assembling the machine, how to connect all the cables. By the way we also offer best aftersales service and detailed manual book, It helps customer to run it automatically by themselves during the Covid situation and save the cost of installation and commissioning.

When you need to produce more than 5 sizes, if economic conditions allow, we recommend that you use a system with automatic size adjustment to save time and effort, but of course you can also choose the equipment according to your specific needs.

If you're interested in our roll forming machine, please contact with LINBAY MACHIENRY.

This cable tray has a design similar to OBO's cable tray, which has an active demand in European market.

The cable tray production line can produce both of cable tray and cover in one machine, this smart technology saves money and space for customer. We use lubrication system at the feeding part of machine to make the finished product has no scratches, specially for galvanized steel.

Using Yangli brand high-speed punch press, the production speed can reach 10m / min. The punch mold uses the type of continuous die to achieve the embossing hole by multiple punchings, which can improve the aesthetics and use strength of the product.

We have made 2 lines for Chinese customer and 1 line for Indonesia customer, this cable tray is more and more popular in market recently.

Our cable tray production line working with Yangli brand punch press, although the perforated type is complicate, the working speed can still reach 15m/min.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor