Flying Saw Cutting Strut Channel Roll Forming Machine

Strut channels are commonly used for solar panel mounting, plumbing and piping, HVAC systems, and more. The common heights of strut channel are 21/41/52/62/71/82mm. The diameter of forming rollers varies depending on the strut channel’s height, and the higher the height, the more forming stations there are. They are usually made from hot-rolled steel, cold-rolled steel, galvanized steel, and stainless steel, with thicknesses ranging from 12 gauge (2.5mm) to 16 gauge (1.5mm).

Note: The forming force required for stainless steel is greater than that for low-alloy steel and regular carbon steel of the same thickness due to the higher yield strength of stainless steel. So, the roll forming machine used for stainless steel raw materials differs from that used for regular carbon steel and galvanized steel.

LINBAY offers production lines that produce multiple dimensions, categorized into manual and automated types based on the automation level for dimension changes.

Flow chart: Decoiler--Servo feeder--Punch press--Guiding--Roll forming machine--Flying saw cutting--Out table

Real case-Main Technical Parameters

1.Line speed: 15m/min, adjustable

2.Suitable material:Hot rolled steel, cold rolled steel, galvanized steel

3.Material thickness: 1.5-2.5mm

4.Roll forming machine: Cast-iron structure

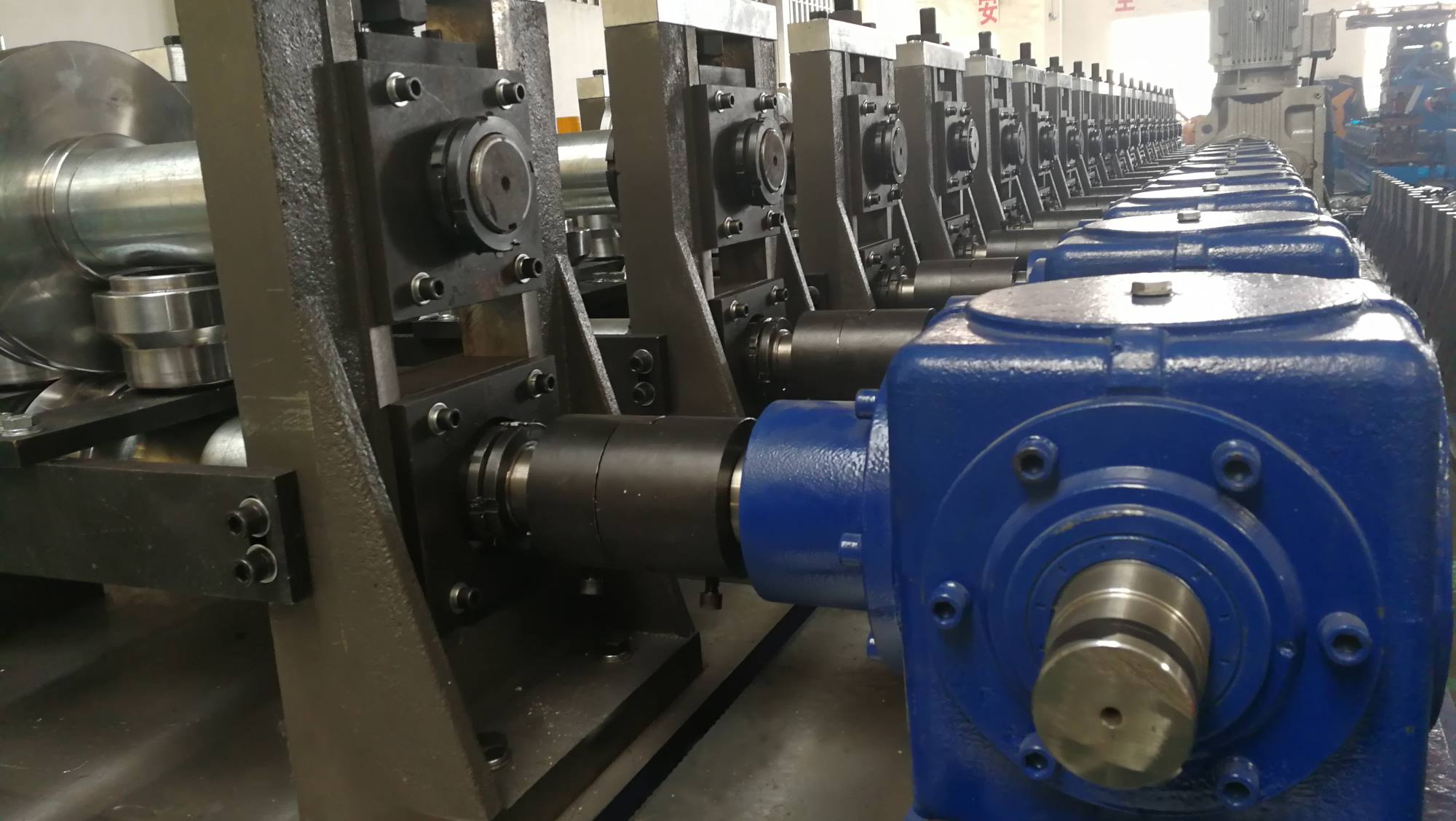

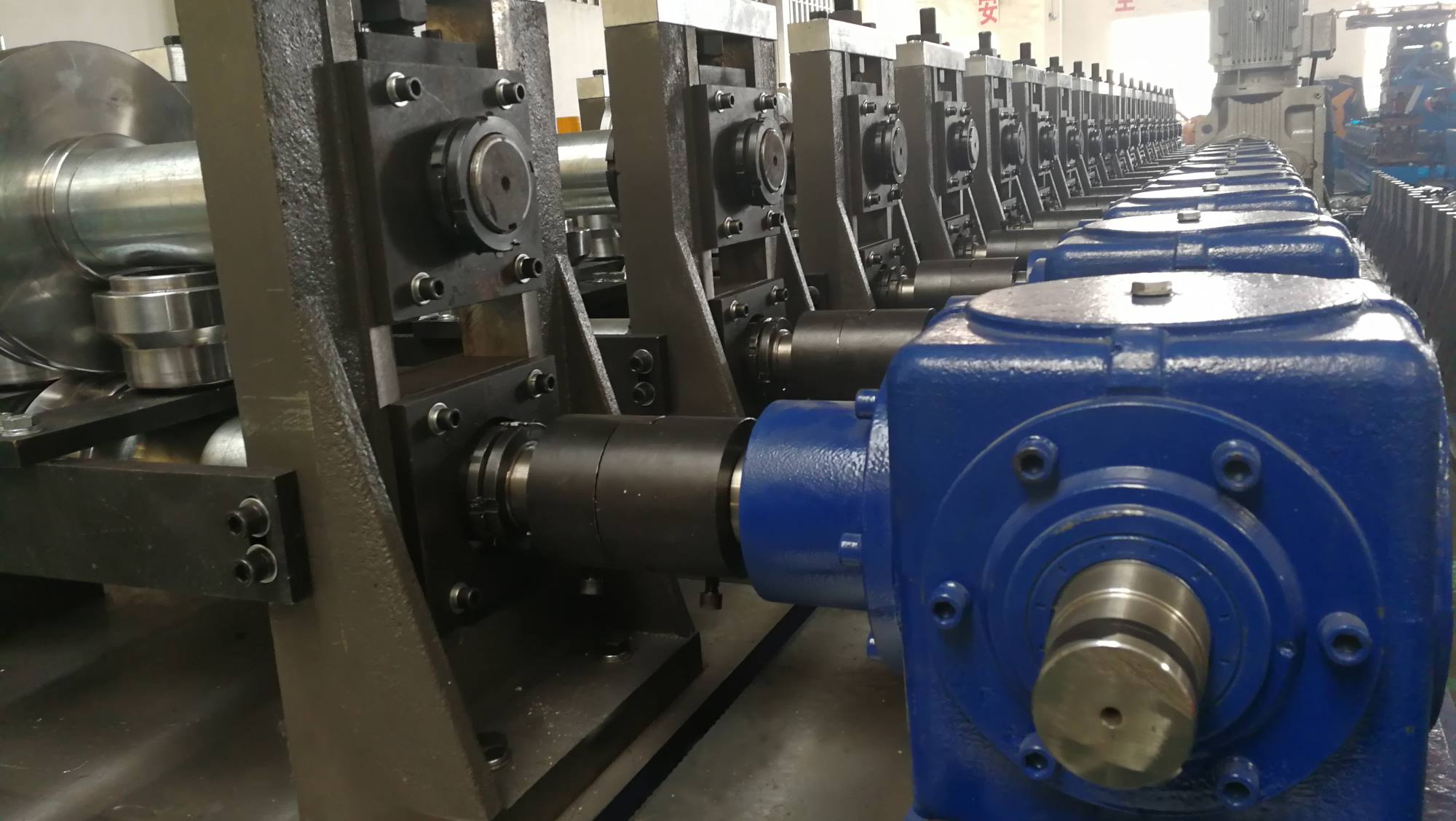

5.Driving system: Gearbox driving system

6.Cutting system: Flying saw cutting. Roll forming machine doesn’t stop when cutting

7.PLC cabinet: Siemens system

Real case-Machinery

1.Hydraulic decoiler with leveler*1

2.Servo feeder*1

3.Punch press*1

4.Roll forming machine*1

5.Flying saw cutting machine*1

6.PLC control cabinet*2

7.Hydraulic station*2

8.Spare parts box(Free)*1

Container size: 2x40GP+1x20GP

Real case-Description

Decoiler with Leveler (2 in 1)

This machine combines the functions of a decoiler and a leveler, saving floor space cost. It is essential to level steel coils thicker than 1.5mm, especially for continuous holes punching of strut channels. The leveler smooths the steel coil and releases internal stress, making it easier to shape and form straight.

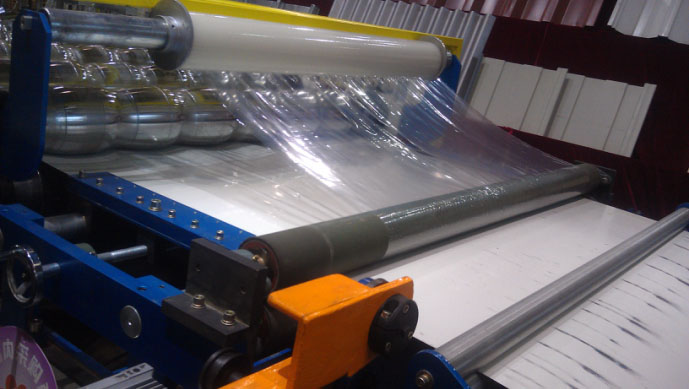

Servo Feeder

A servo feeder gets the name cause it’s powered by a servo motor. Due to the servo motor's minimal start-stop delay, it provides exceptional accuracy in steel coil feeding. This accuracy is crucial for maintaining tight tolerances and reducing steel coil waste when producing strut channels. Additionally, pneumatic clamps inside the feeder advance the steel coil while protecting its surface from scratches.

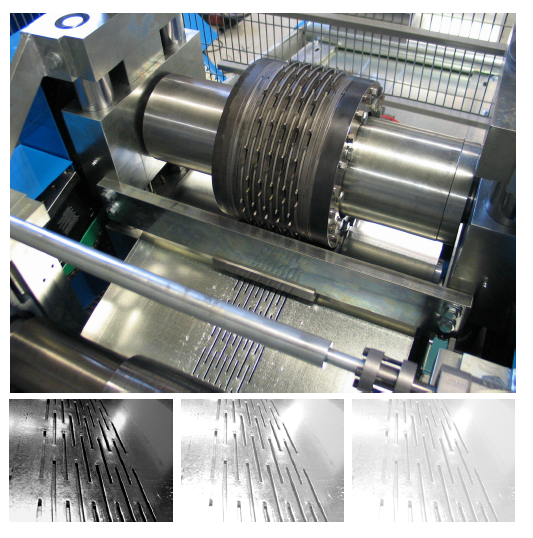

Punch Press

A punch press is used to punch holes in the steel coil, which are necessary for installing screws and nuts to secure the strut channels. The punch press operates faster than an integrated hydraulic punch (on the same base as the roll forming machine) and a standalone hydraulic punch. We use punch presses from the renowned Chinese brand Yangli, which has multiple offices worldwide, making after-sales service and purchasing replacement parts convenient.

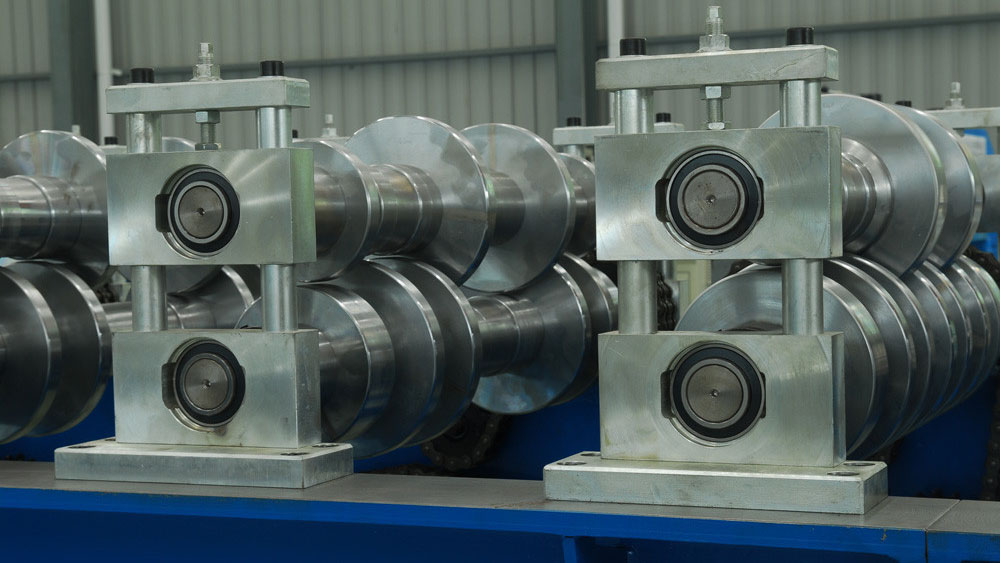

Guiding

Guide rollers ensure that the steel coil and machines stay aligned along the same centerline, maintaining the strut channel's straightness. This helps the strut channels match with other profiles during installation, directly affecting the stability of the entire construction structure.

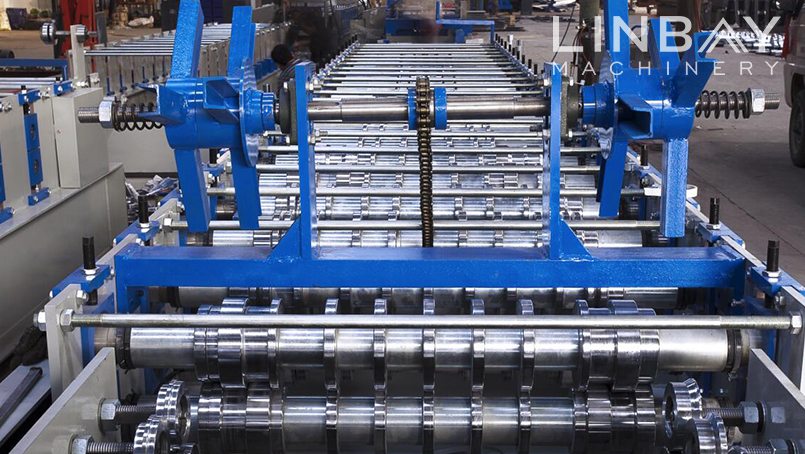

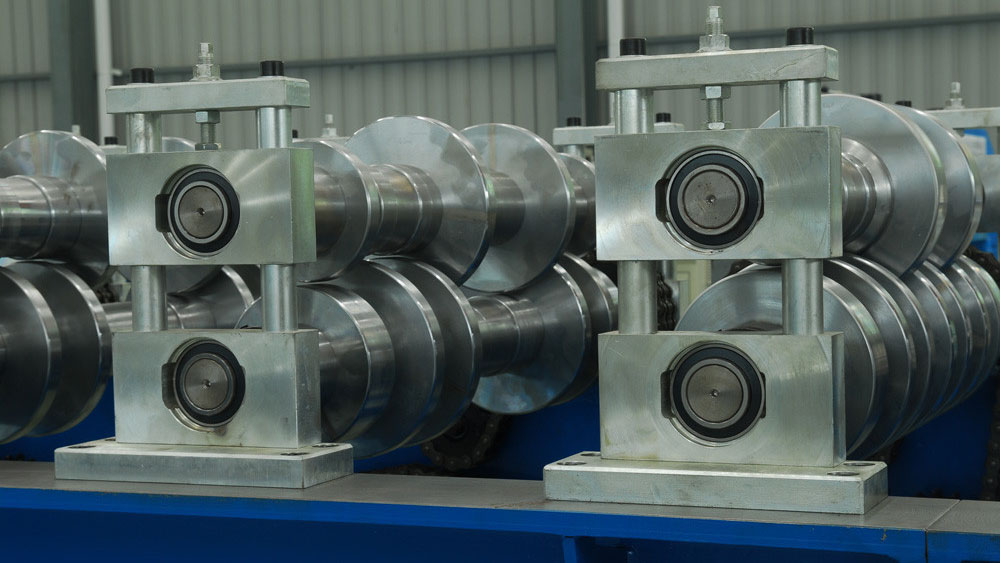

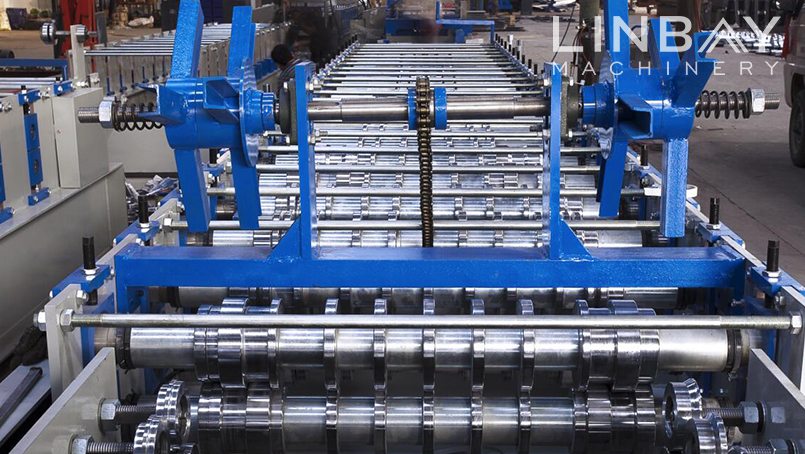

Roll Forming Machine

The roll forming machine features a cast-iron structure, made from the single piece of steel, ensuring exceptional durability. The upper and lower rollers apply force to shape the steel coil, driven by a gearbox to ensure adequate power for forming.

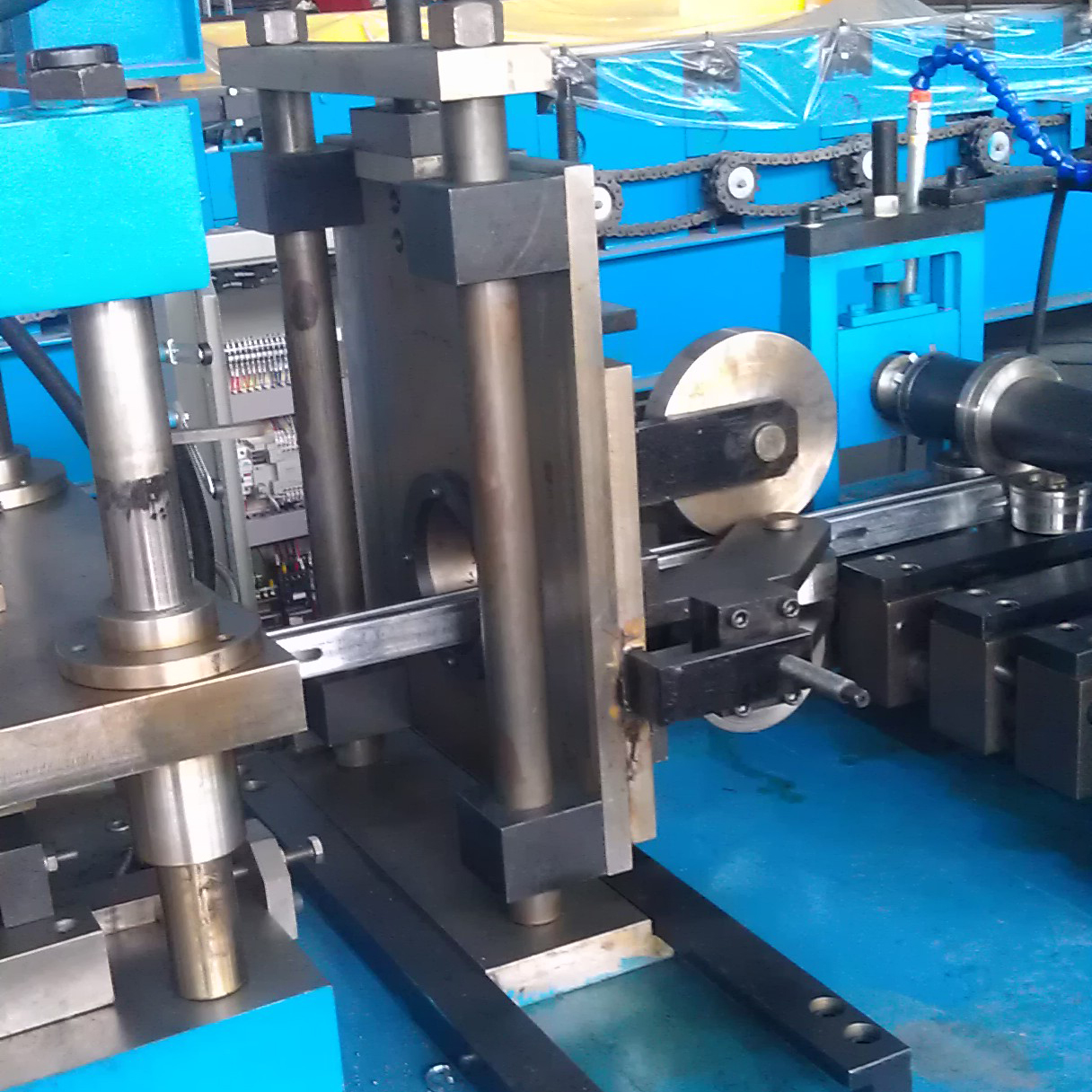

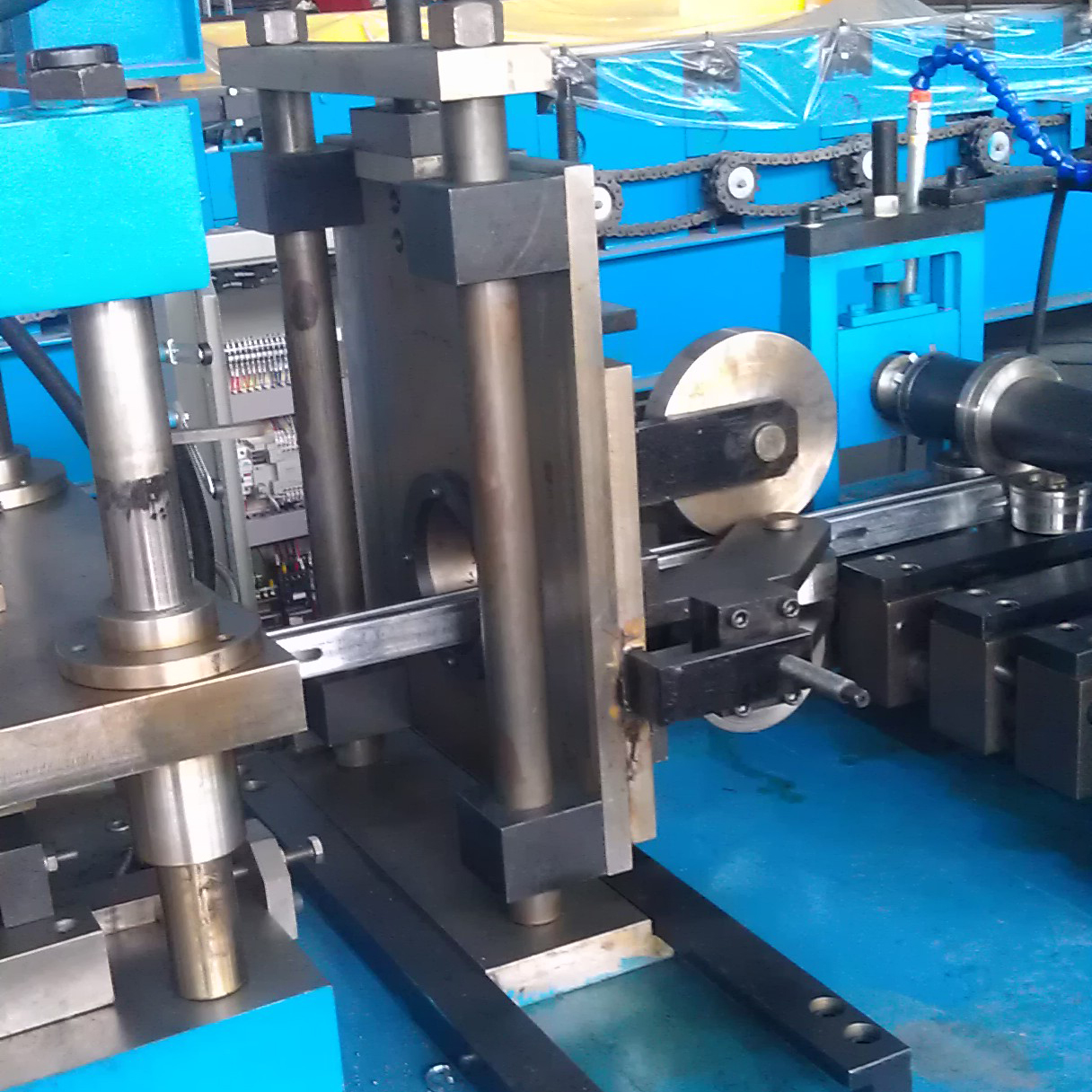

Flying Saw Cutting

The flying saw cutter's carriage accelerates to match the speed of the moving strut channels (also the speed of the roll forming machine), allowing for cutting without stopping the production process. This highly efficient cutting solution is ideal for high-speed operations and produces virtually no waste.

During cutting, the saw blade base moves toward the strut channel using pneumatic power, while hydraulic power from the hydraulic station drives the rotation of the saw blade.

Hydraulic Station

The hydraulic station provides the necessary power to operate equipment such as the hydraulic decoiler and hydraulic cutter, and equipped with cooling fans for efficient heat dissipation.

For hot climates, we recommend increasing the hydraulic reservoir size to enhance heat dissipation and provide a larger volume of fluid for heat absorption. These methods help maintain a stable operating temperature during extended operation, ensuring the roll forming production line's reliability and efficiency.

PLC Control Cabinet & Encoder

Encoders are essential for providing feedback on position, speed, and synchronization. They convert the measured length of the steel coil into electrical signals sent to the PLC control cabinet. The control cabinet display allows operators to manage production speed, output quantity per cycle, cutting length, and more. With accurate measurement and feedback from encoders, the cutting machine can maintain a cutting error within ±1mm.

Flying hydraulic cutting VS Flying saw cutting

The cutting blade: The flying hydraulic cutter requires one standalone cutting blade for each dimension. However, saw cutting isn’t limited by the dimension of strut channels.

Wear and Tear: Saw blades wear out faster than hydraulic cutting blades and need more frequent replacement.

Noise: Saw cutting can be noisier compared to hydraulic cutting, potentially requiring more soundproofing in the production area.

Waste: Even when calibrated, a hydraulic cutter generates an unavoidable 8-10mm of waste with each cut. In contrast, a saw cutter produces almost no waste.

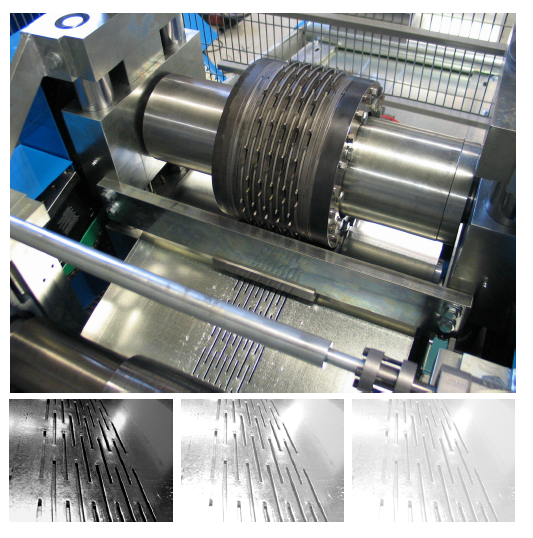

Maintenance: Saw blades need a coolant system to reduce heat from friction for continuous, efficient cutting. Hydraulic cutting maintains a more stable temperature.

Material limitation: Stainless steel has a higher yield strength compared to regular carbon steel. When using stainless steel as the raw material, only the saw cut is required for cutting.

1. Q: What kinds of experience do you have in producing solar photovoltaic stents roll forming machine?

A: We have experience of exporting our solar photovoltaic stents roll formers to Saudi Arabia, Turkey, Iraq, India, Kuwait, Qatar, Pakistan, Argentina etc. We have produced solid channels, slotted channels, punched channels, standard channels, American standard racks etc. We are confident to solve your solar racking problem.

2. Q: How many sizes can be made in one machine?

A: One machine could produce one same width with different heights like 41x21, 41x41, 41x62, 41x82 or 27x18, 27x30.

3. Q: What is delivery time of solar photovoltaic stents roll forming machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. if you want a higher speed like 40m/min, we give you a solution with rotary punch system, which punch speed is up to 50m/min.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

American standard profiles:

-

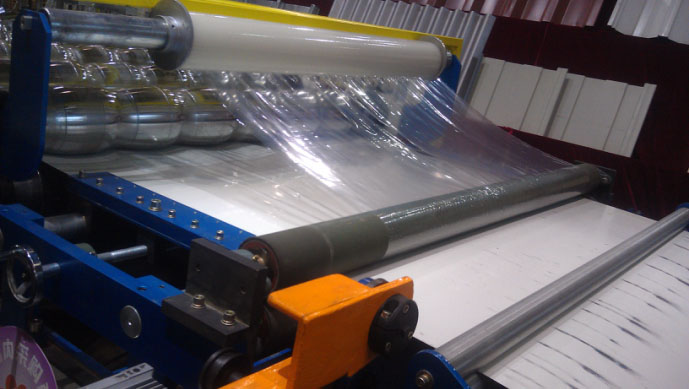

Others

-

scrap collector

-

pasting

-

mould change

-

guiding head

-

Cooling system

-

-

Out table

-

non-powered

-

auto stacker

-

-

Cutting

-

saw cutting

-

flying shear

-

-

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for Cpurlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-