.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)

The Strut channel is used for supporting and connecting lightweight structural loads in building construction. Common dimensions for strut channels include 41*21mm, 41*41mm. Typically, it is manufactured from hot-rolled steel, cold-rolled steel, or galvanized steel with a thickness ranging from 2-2.5mm.

Flow chart

Manual decoiler--Guiding--Hydraulic punch--Roll forming machine--Hydraulic cut--Out table

Main Techinical Parameters

1. Line speed: 0-12m/min without punching, 3m/min with punching.

2. Material thickness: 2mm in this case.

3. Suitable material: Hot rolled steel, cold rolled steel, galvanized steel.

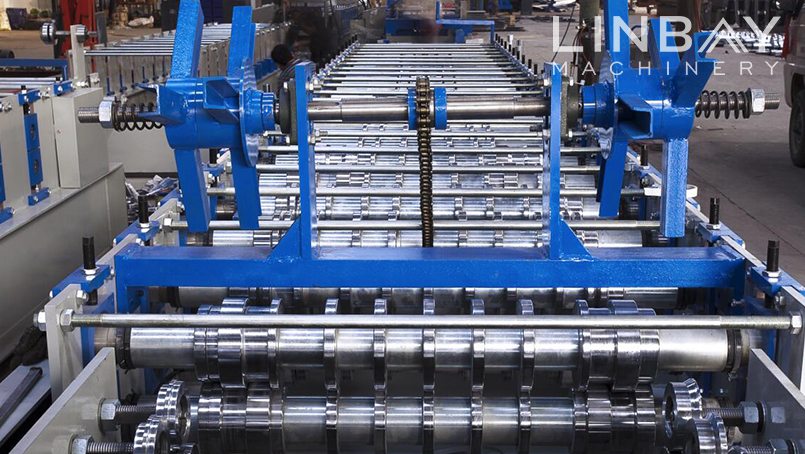

4. Roll forming machine: Wall-panel structure and chain driving system.

5. Of forming station: 20

6. Punching system: Hydraulic, roll former stops when punching.

7. Cutting system:Hydraulic, roll former stops when cutting.

8. Changing size: 2-3 hours manually.

9. PLC cabinet: Siemens system.

Real case-Description

Manual Decoiler

The manual decoiler features a brake device that adjusts the core expansion ranging from φ490-510 mm, ensuring a smooth uncoiling process. Additionally, the outward coil retainer prevents coil slippage, enhancing cost-effectiveness and safety.

For higher production demands, we offer an optional hydraulic decoiler powered by a hydraulic station.

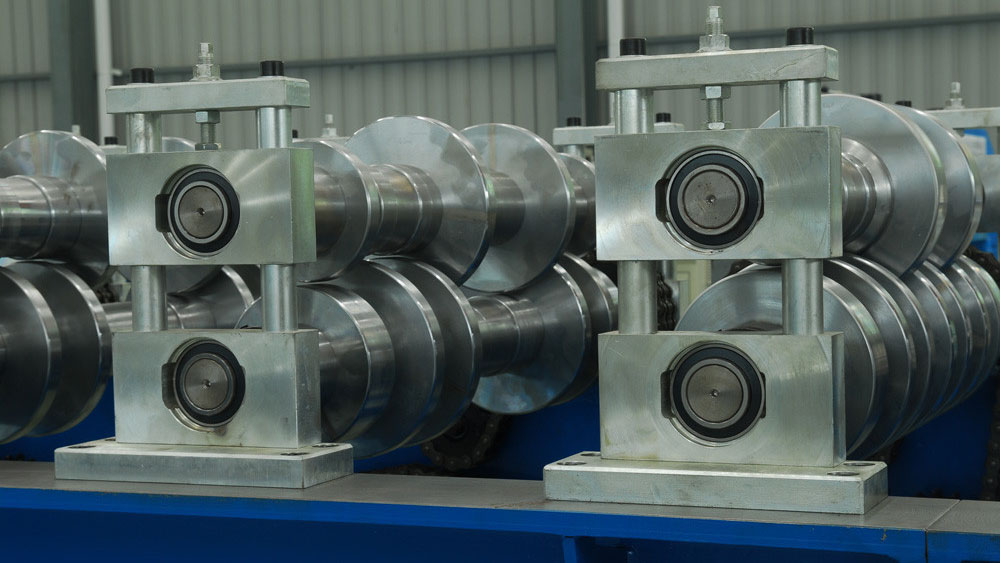

Guiding

Guiding rollers play a crucial role in maintaining alignment between the steel coil and the machine, preventing distortion of the strut channel.

They also contribute to the forming process, preventing rebound deformation of the strip steel. The straightness of the tube beam is vital for product quality, impacting the supporting performance of the entire installation frame. Guiding rollers are strategically installed along the entire roll forming machine, not only at the inlet. Before shipment, we measure the distance from each guiding roller to the machine's edge and document these measurements in the manual. In slight displacements during transportation or the production process, workers can use this recorded data to reposition the rollers accurately.

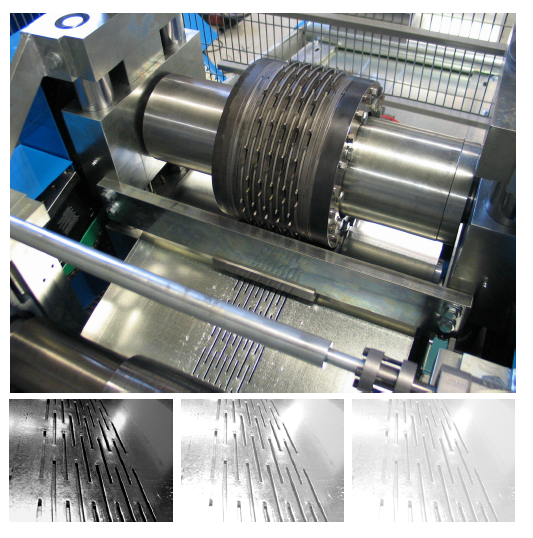

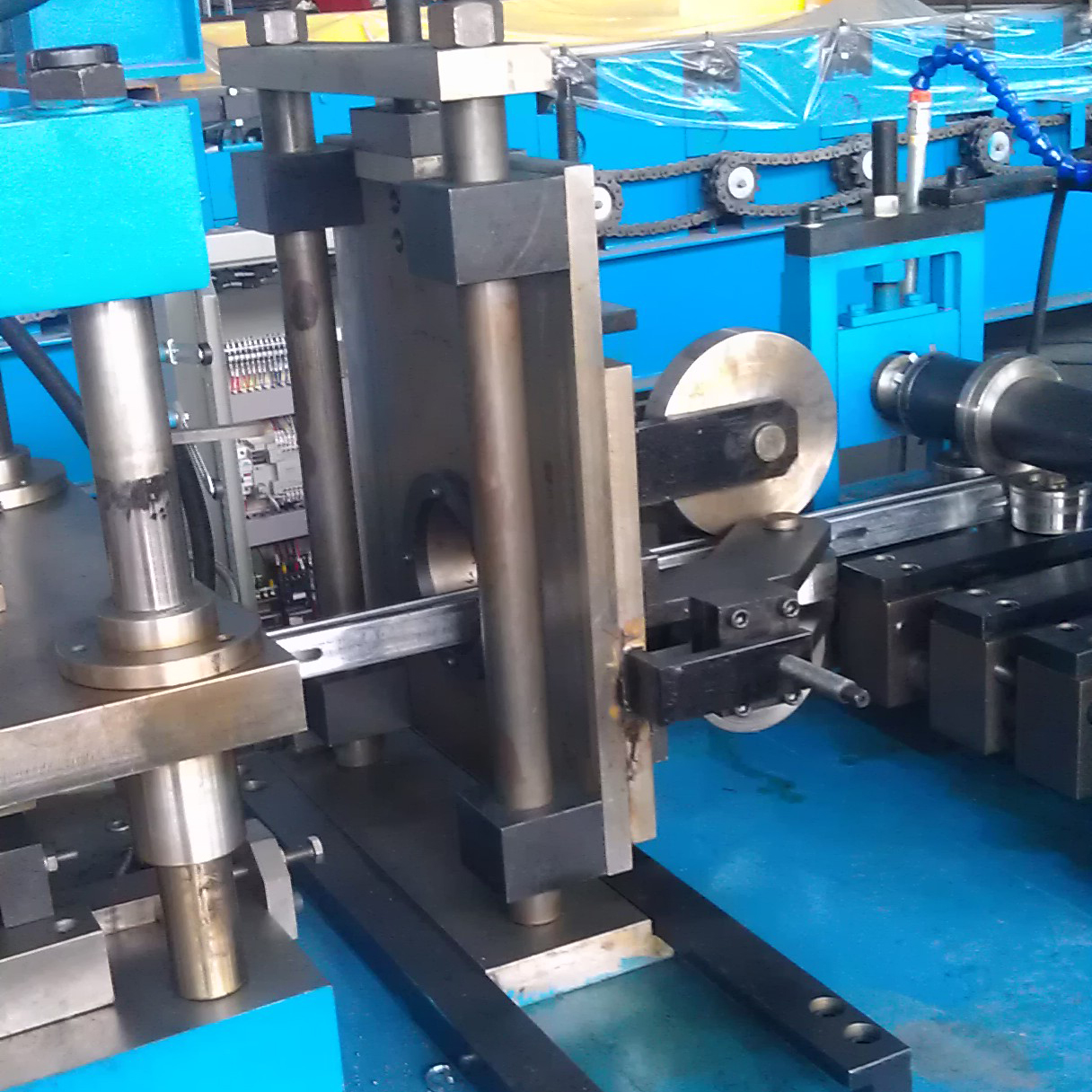

Hydraulic Punch

This hydraulic punch with the punching step 400mm, powered by a hydraulic station, is positioned in front of the roll forming machine, requiring a stop of the roll forming machine during punching. For higher production speed, we recommend independent hydraulic punching solution customized based on provided punching drawings.

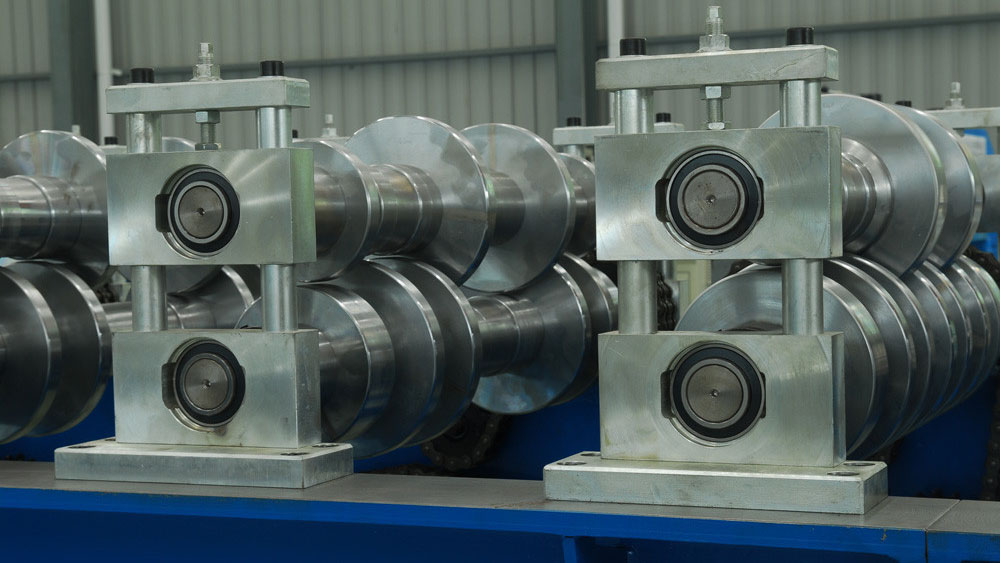

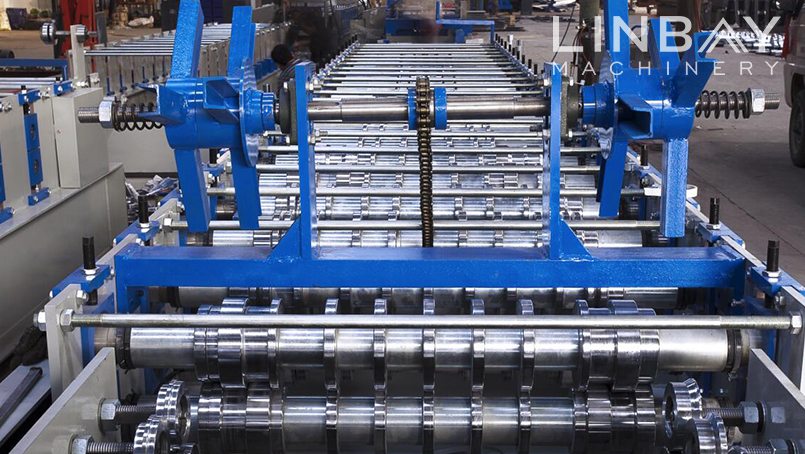

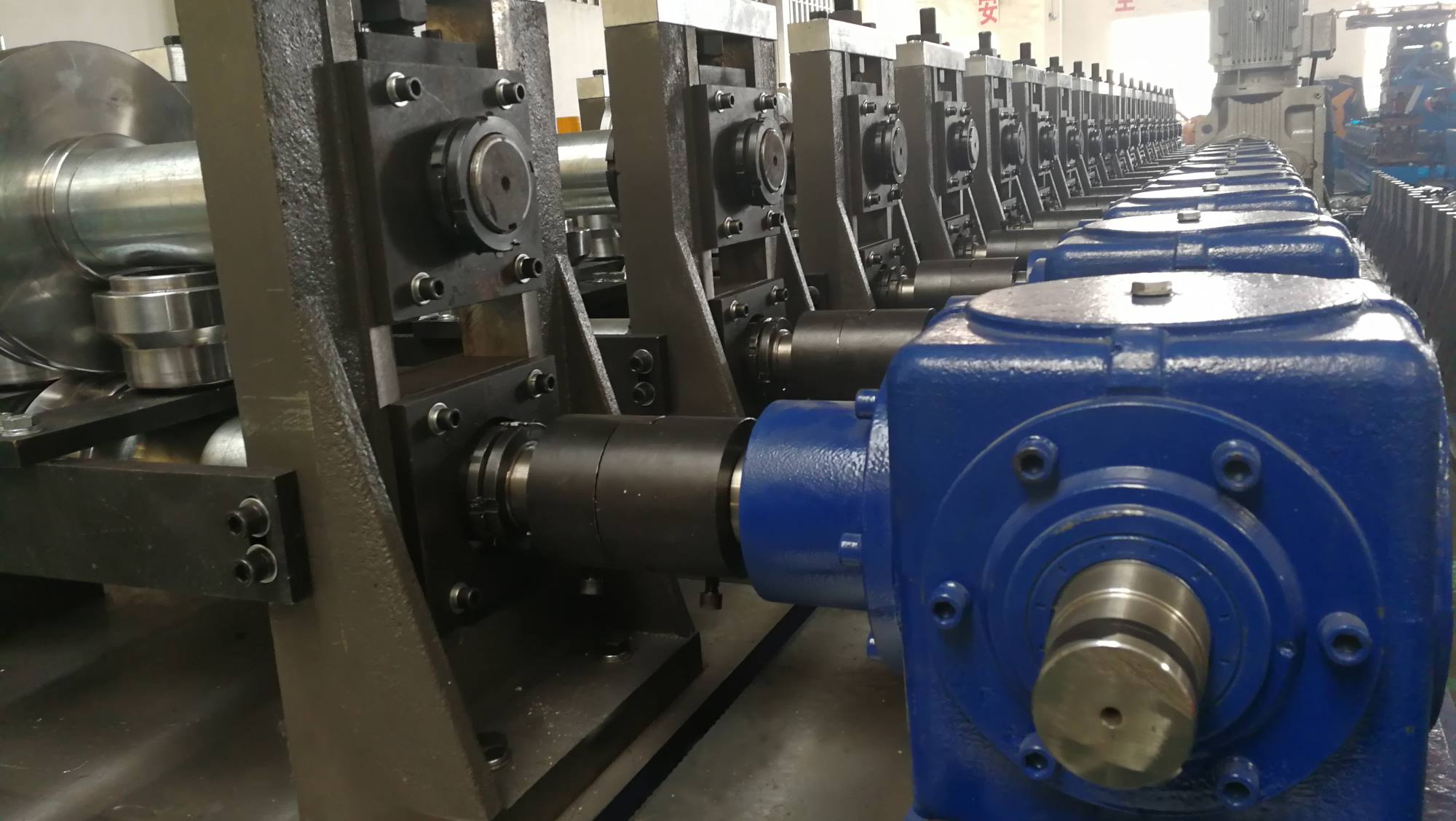

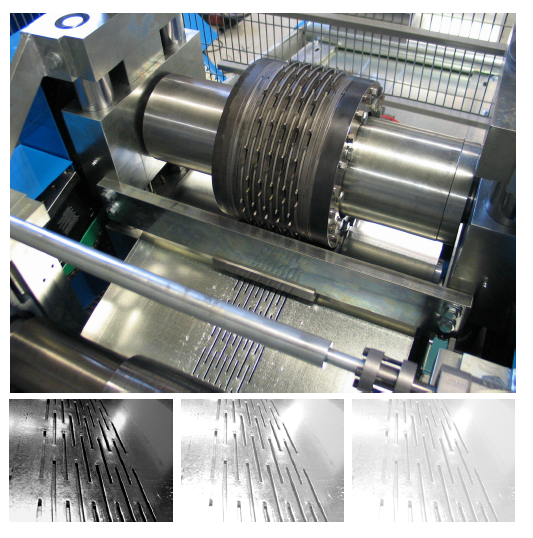

Roll Forming Machine

The roll forming machine is designed as the wall panel structure and a chain-driving system. This line offers a cost-effective manual size change solution with a replacement time of approximately 2-3 hours.

Changing the forming points is key to altering sizes. By loosening the shims at the left or right ends of the rollers, and replacing/adding the C-shaped collar rollers (Sleeves) to the correct position of the profile new size, the forming point shifts. We also offer an automatic size change solution with a replacement time of about 10 minutes.

Video link to -【Installation】Linbay Change sleeves for roll forming machine

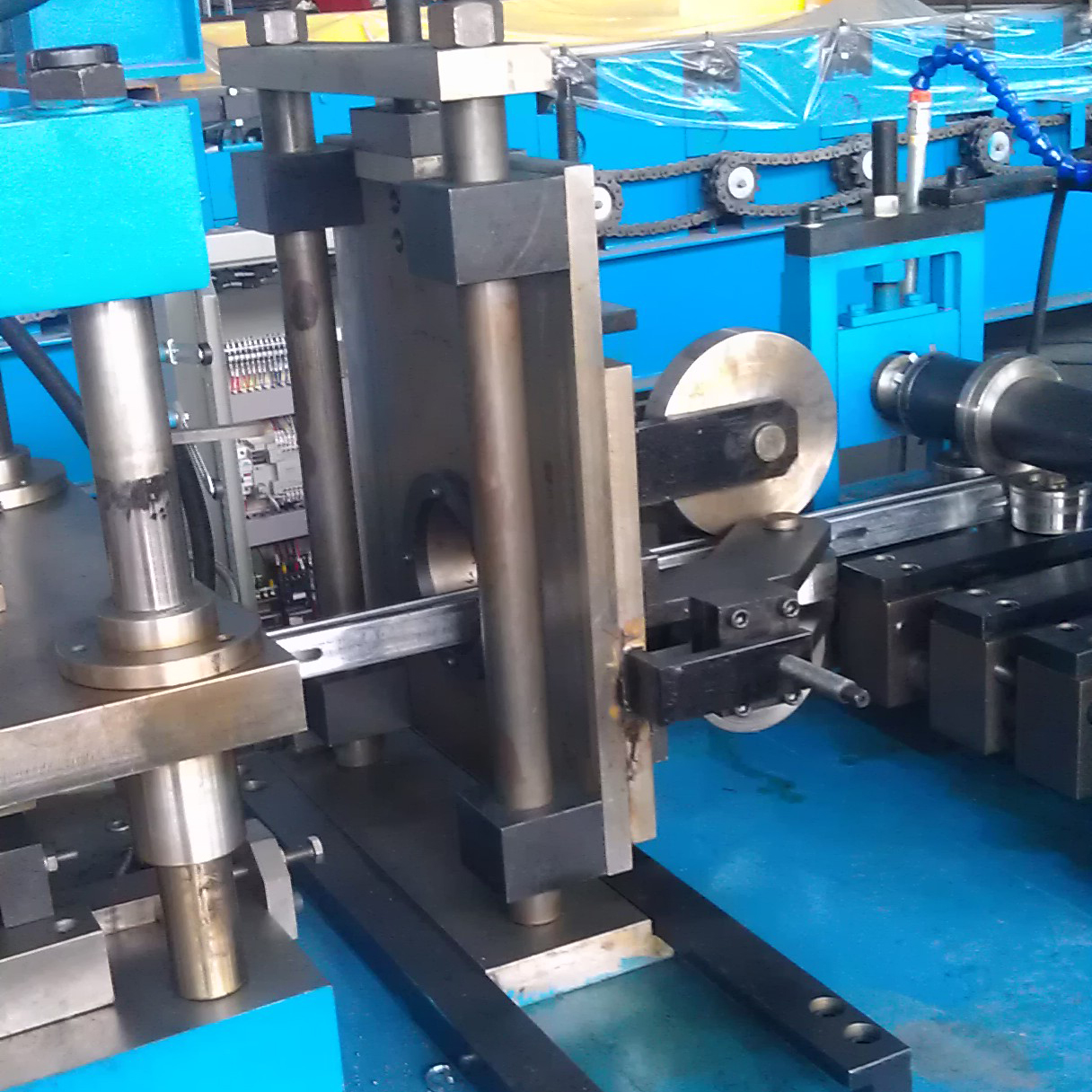

Hydraulic Cut

This hydraulic cutting machine, powered by a hydraulic station, efficiently cuts steel coils with a thickness of 2mm. The cutting blades conform to the profile shape, generating approximately 8mm of waste material per cut, but with almost no burrs on the cutting surface.

Encoder & PLC

The encoder of Japanese brand koyo in the roll forming machine converts sensed coil lengths into electrical signals transmitted to the PLC control cabinet. This ensures cutting errors are controlled within ±1mm, guaranteeing the production of high-quality products and avoiding waste from incorrect cuts. The PLC screen allows operators to control production speed, production dimensions, cutting length, etc. It has memory storage function for commonly used parameters and protection functions such as overload, short circuit, and phase loss.

The language on the PLC screen can be customized based on customer preferences.

Hydraulic Station

Our hydraulic station is equipped with cooling electric fans to efficiently dissipate heat, ensuring prolonged and reliable operation with a low failure rate, adapting to a hot working environment.

Warranty

On the day of shipment, the current date will be engraved on the metal nameplate, marking the commencement of a two-year guarantee for the entire production line and a five-year warranty for rollers and shafts.

1. Q: What kinds of experience do you have in producing solar photovoltaic stents roll forming machine?

A: We have experience of exporting our solar photovoltaic stents roll formers to Saudi Arabia, Turkey, Iraq, India, Kuwait, Qatar, Pakistan, Argentina etc. We have produced solid channels, slotted channels, punched channels, standard channels, American standard racks etc. We are confident to solve your solar racking problem.

2. Q: How many sizes can be made in one machine?

A: One machine could produce one same width with different heights like 41x21, 41x41, 41x62, 41x82 or 27x18, 27x30.

3. Q: What is delivery time of solar photovoltaic stents roll forming machine?

A: 80 days to 100 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. if you want a higher speed like 40m/min, we give you a solution with rotary punch system, which punch speed is up to 50m/min.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

American standard profiles:

-

Others

-

scrap collector

-

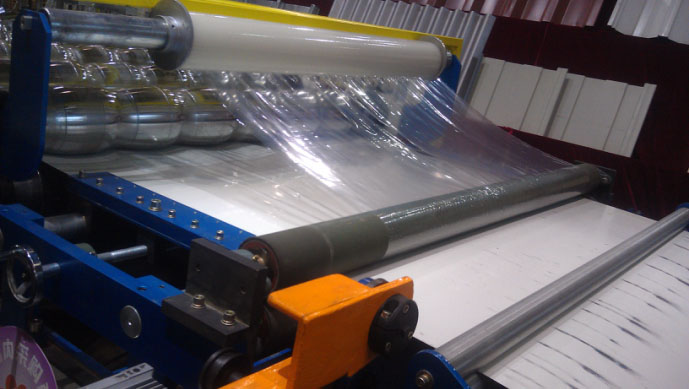

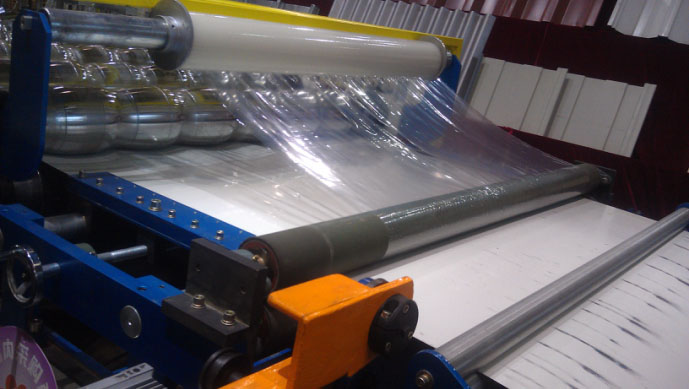

pasting

-

mould change

-

guiding head

-

Cooling system

-

-

Out table

-

non-powered

-

auto stacker

-

-

Cutting

-

saw cutting

-

flying shear

-

-

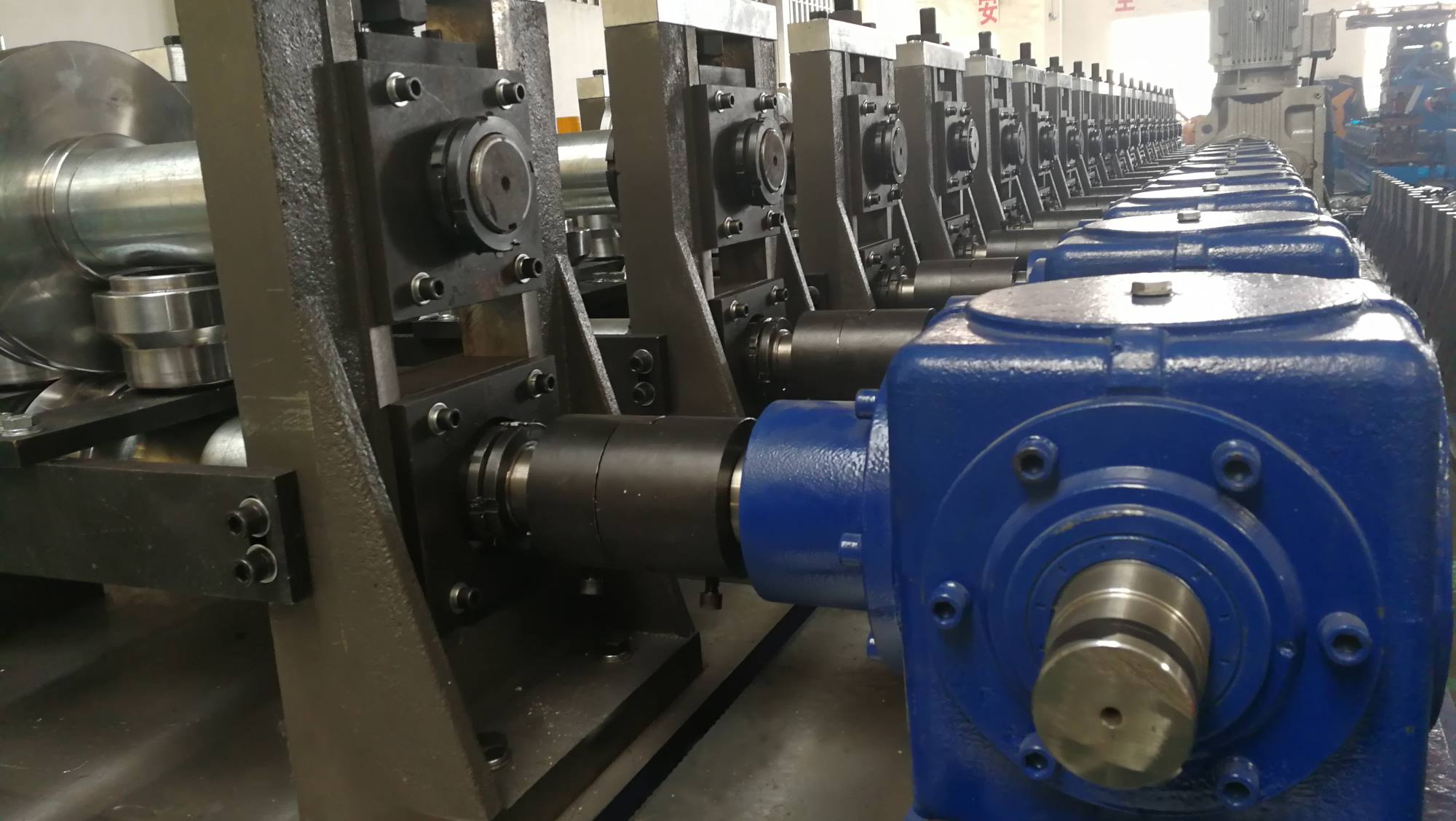

Driving

-

chain drive

-

gearbox drive

-

gearbox drive with coupling

-

-

Stands

-

wall panel stands

-

torri stands

-

forged iron stands

-

wall panel for Cpurlin

-

-

Punching

-

hydraulic punching station

-

punching press

-

roller punching

-

-

Feeding

-

leveling

-

servo feeding

-

-

Decoiler

-

manual decoiler

-

hydraulic decoiler

-

double head decoiler

-