Roll Forming Machine for Posts and Channels with Automatic Size Adjustment System

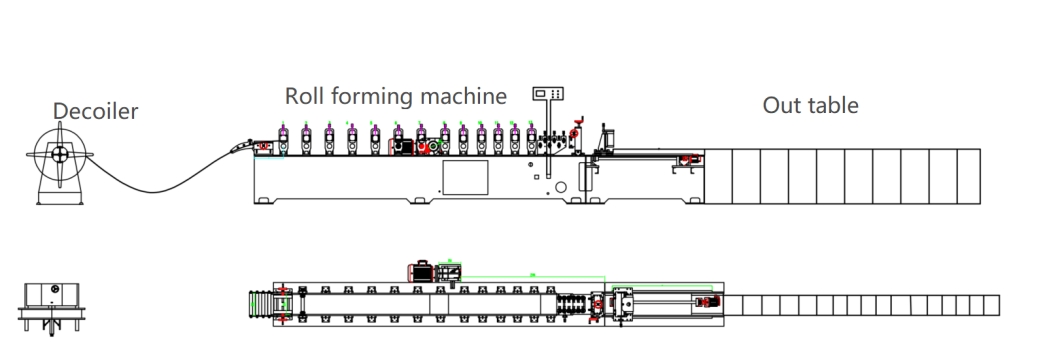

At Linbay Machinery, we design and manufacture innovative solutions for the production of drywall studs and tracks. Our new roll forming machine allows for automatic changes between different profile sizes, drastically reducing changeover time and increasing production efficiency. (Machine explanation video) Automatic size change can significantly reduce adjustment time; manual mold change takes approximately 2–3 hours. With the automatic lateral shifting system, it only takes 10 minutes, making it more suitable for beginners as it is easy to operate and learn.

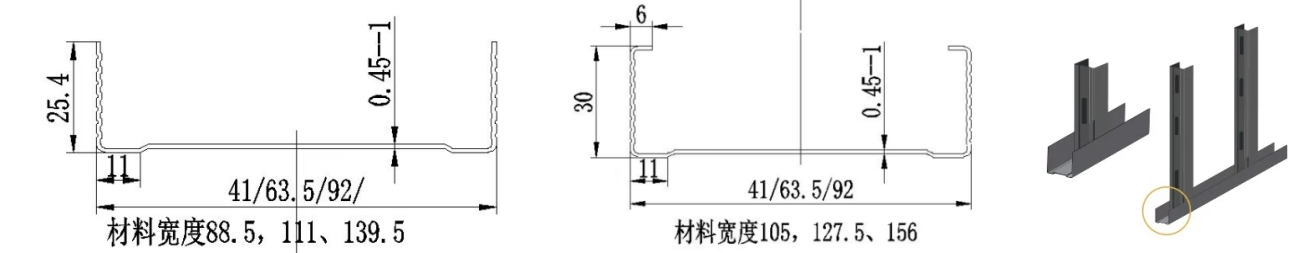

The roll forming machine produces high-quality profiles that meet the construction standards, including posts and channels profiles (studs and tracks). The thickness of the profile ranges from 0.45 to 1 mm, equivalent to gauge 20-26. The widths are 41, 63.5, and 92 mm. The two profiles must be assembled as shown in the image. The machine includes a punching station and two sets of molds, and is suitable for producing posts in three different widths.

Our roll forming machine integrates the following advantages:

- Automatic size change through lateral movement, eliminating the need to manually change tools. (Comparative video between automatic change and manual spacer change)

- High production speed to meet large order volumes.

- Precise punching system tailored to the profile.

- Smart PLC control for simpler and more reliable operation. The screen language can be customized to facilitate worker operation.

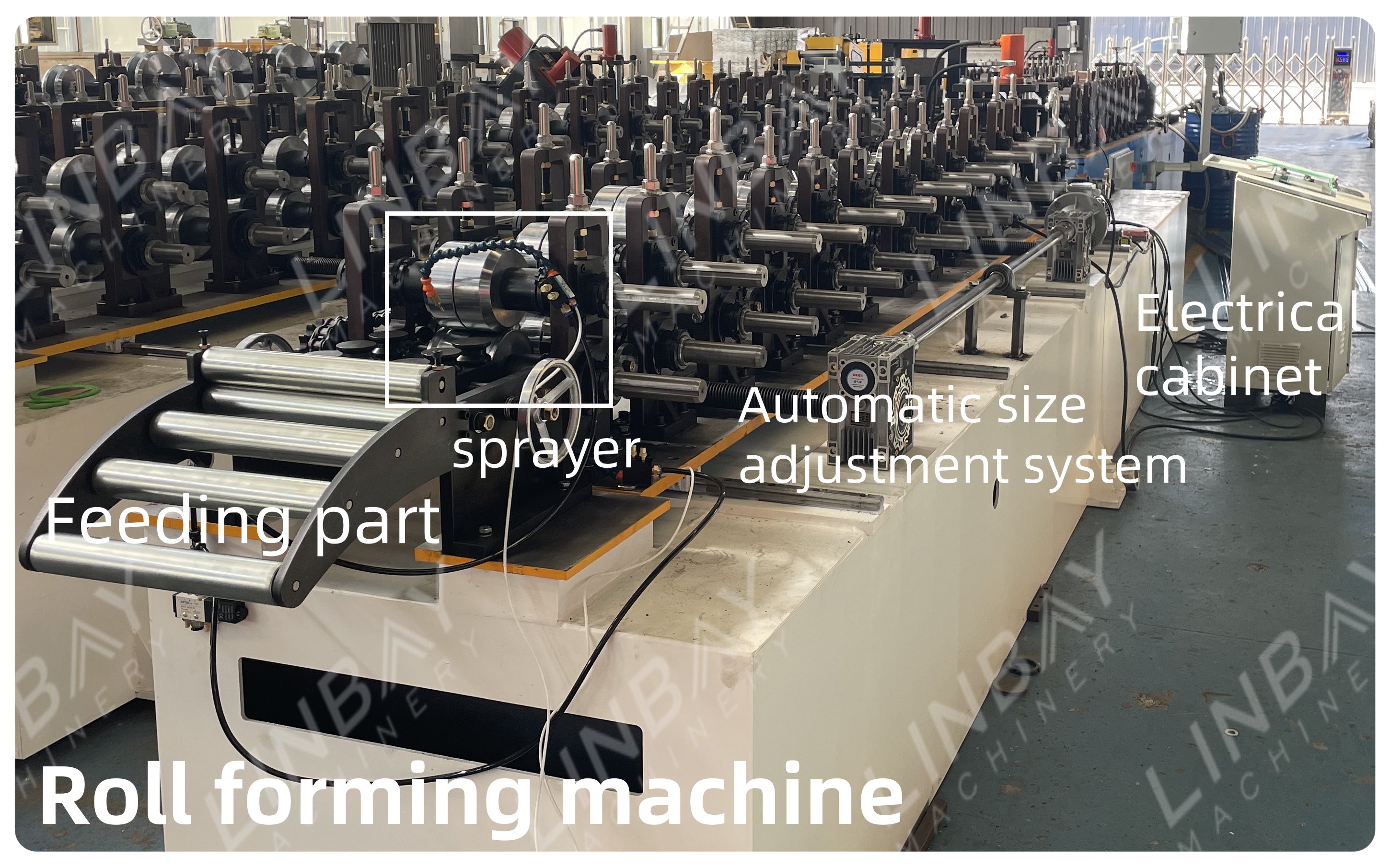

- Feeder: The feeder can adjust the width using two manual handwheels, as the production of different profile sizes involves the use of steel coils with varying widths.

- Sprayer: Since galvanized steel coils are used for the production of studs and tracks, a sprayer is equipped on the first forming roller to spray cutting fluid and protect the zinc coating.

- Automatic adjustment system: With the automatic device, the production size can be easily adjusted. This helps save time and labor costs. The specific operating steps can be seen in the video. (Machine explanation video)

- Electrical cabinet: Production can be easily carried out through the buttons on the electrical cabinet and the control panel. The screen language can be customized according to the customer's needs.

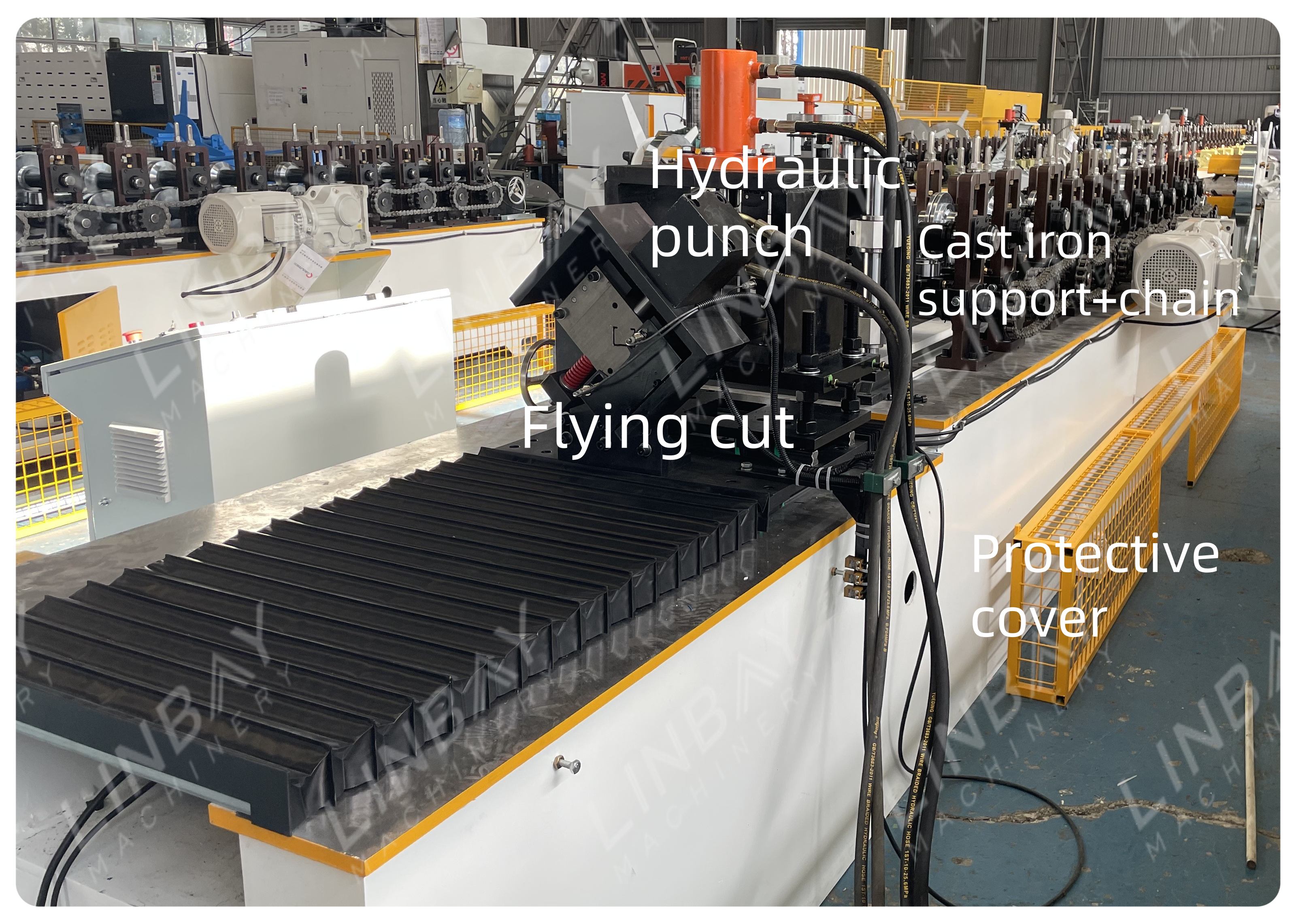

- Hydraulic press: Since the studs require perforations to allow the passage of electrical cables, it is necessary to perforate before cutting during the production of the C profile. The distance between the holes can be set from the control panel. The shape change of the holes can be achieved through customized molds.

- Protective casing: The casings are used to cover the chain, serving a protective function. This is because during the machine's operation, the chain rotates, presenting certain risk factors.

- Flying cutting: First, we use the waste-free cutting, which helps save material usage. Second, the Flying cut can significantly increase the production line speed, improving efficiency. This is because, with machine stop cutting, the roll former needs to stop every time a cut is made.

| Roll forming machine for posts and channels with automatic size adjustment system | ||

| Item | Optional configuration | |

| Raw materia: | Galvanized steel | Thickness (MM): gauge 20–26 / 0.45–1mm |

| Yield strength: | ≤350 Mpa | |

| Line speed: | 0-30m/min | |

| Forming speed: | 0-30m/min | |

| Forming step: | 12 | * According to your profiles |

| Decoiler: | Manual decoiler | 1.5ton |

| Main motor: | 5.5kw | |

| Size adjustment motor: | 1.5kw | |

| Transmission system: | Chain | |

| Machine structure: | Cast iron support | |

| Shaft material: | 40Cr | |

| Shaft diameter: | φ70mm | |

| Roller material: | GCr15, HRC58-62° | |

| Cutting system: | Flying hydraulic cut | |

| Servo motor power: | 3kw | Delta Brand |

| Hydraulic motor power: | 4kw | |

| Size change method: | Automatic | |

| Encoder: | Koyo Brand | |

| Inverter: | Delta Brand | |

| PLC: | Delta Brand | * Siemens (opcional) |

| HMI: | Delta Brand | * Siemens (Opcional) |

| Language: | English | |

| Electricity : | 220V 60Hz | * 440V 60Hz |

| Machine color: | White | * Or according to your requirements |

| Delivery: | 90 Days | |

| Container: | 1*20GP | |

| Total weight: | 4.3ton | |

| Dimensions: | 16m*1.3m*1.5m | |

At Linbay Machinery, we have engineer to provide direct support for installation, commissioning, and maintenance. After delivering the machine to our customer, our team was present to ensure its proper operation. Watch how the machine operates perfectly in the installation video at the factory. With our technical support, you can rest assured knowing that you will always have assistance available to keep your production running smoothly without interruptions.