Description

The container system is the latest new system pioneered by Linbay. The container machine is a machine for manufacturing standard 20/40 GP container corrugated panels and consists of four main parts: shipping container roof machine, shipping container side machine,shipping container end machine and shipping container door machine. For producing Shipping containers panels, wall panels are cut down from the large steel sheets into smaller sheets and a metal roll forming process use to create the wanted form.The sheets are then waved and corrugated. The corrugation,which gives the walls their wave-like texture adds strength to the container. Next, the smaller panels are laid out and welded together to create the full-sized wall panel. Finally square tubing weld onto the top and bottom of the wall.This tubing allows the walls to weld to the floors and roof of the container. The general thickness is about 2mm, and hot rolled steel is used as the raw material. The side panel has an important role in the container system.

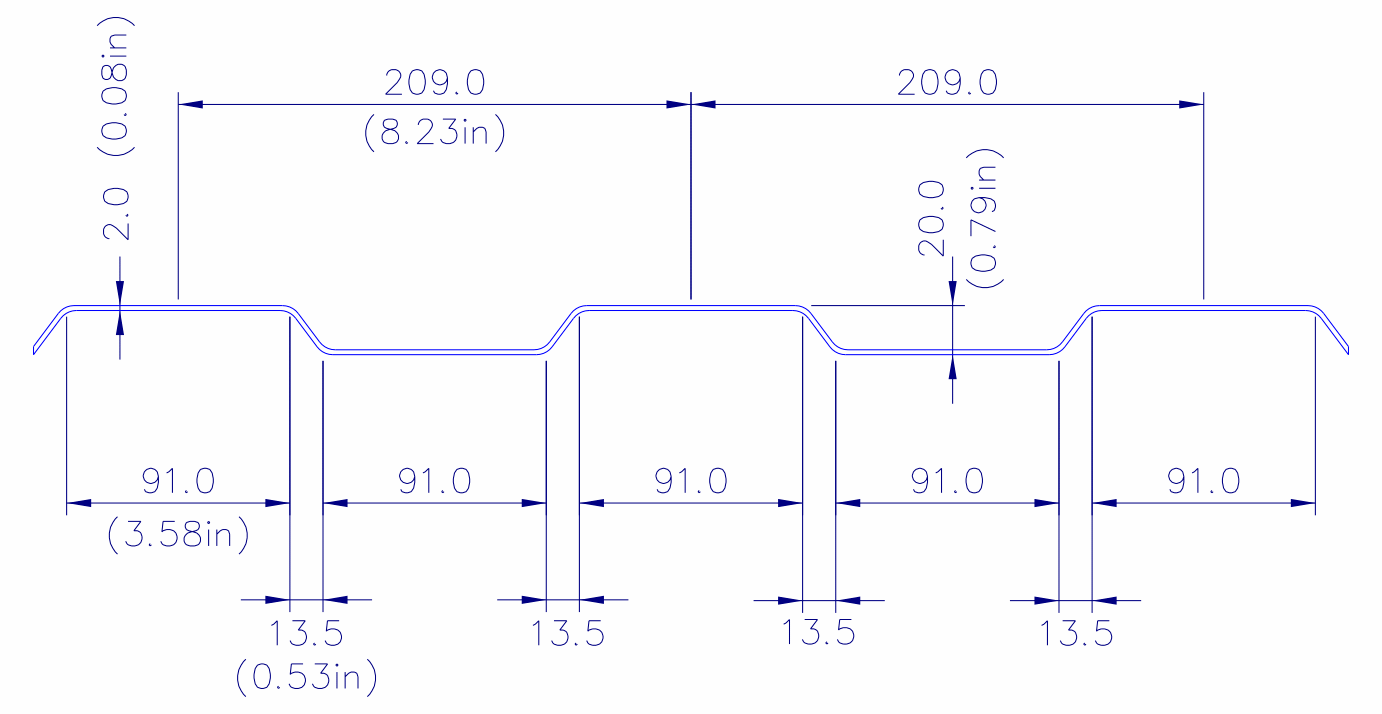

The CONTAINER ROOF CORRUGATION SIDE FORMING MACHINE is used in container systems and is a machine for making standard 20GP container side panels. The sides of a container typically have vertical corrugations.The overall thickness of the corrugation is what contributes to the loss in the interior width of a container, which is why this corrugation, in particular, is important to pay attention to.

Flow chart

Manual feeder table-Roll former-Out table

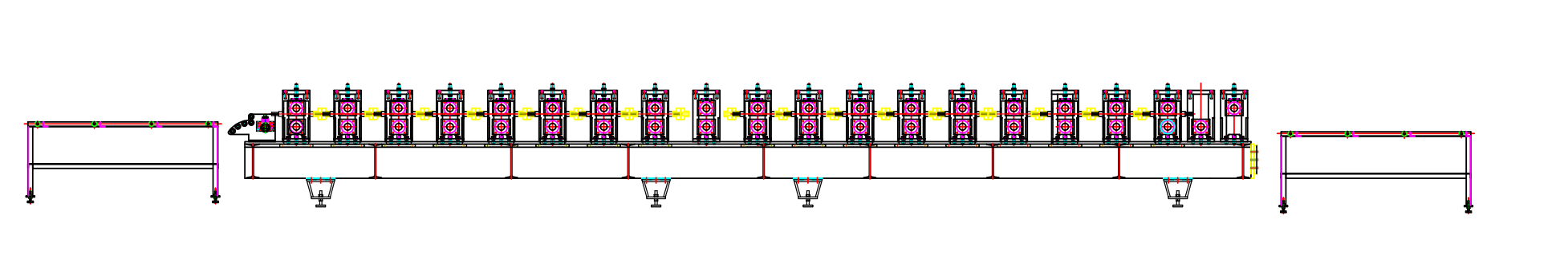

This container side corrugation roll forming machine has 3 sections. At the beginning, it is equipped with a manual feeder table. For such a machine, we usually use a single steel feeding. Manual feeding table can help us to assist feeding. Its feeding width is 1220mm. The raw material of the coil should be hot rolled steel and its normal thickness is around 2mm. This whole production line weighs almost 14 tons. Regarding the main part of the roll forming machine, we adopt the iron cast structure driven by gearbox, which can ensure the stability of the machine and the speed of production at the same time. We have 22 forming stations, for which we are equipped with 2 x 22 kW motors. The speed of the production line can reach 12m/min.

Technical Specifications

| Machinable Material: | Hot rolled steel | Thickness(MM): 2-2.5 |

| Forming station: | 22 stands | *According to your profile drawing |

| Driving system: | Gearbox drive | |

| Machiner structure: | Cast iron station | |

| Forming speed: | 12M/MIN | |

| Rollers' material: | GCr15 | *Cr12Mov |

| Shafts' material: | 40Cr heat treatment | |

| Shafts' diameter: |

Lower shafts 100mm Upper shafts 135mm |

|

| PLC brand: | Siemens | |

| Power supply: | 380V 50Hz 3Ph | *Or according to your requirements |

Related machines

- Shipping container roof roll forming machine

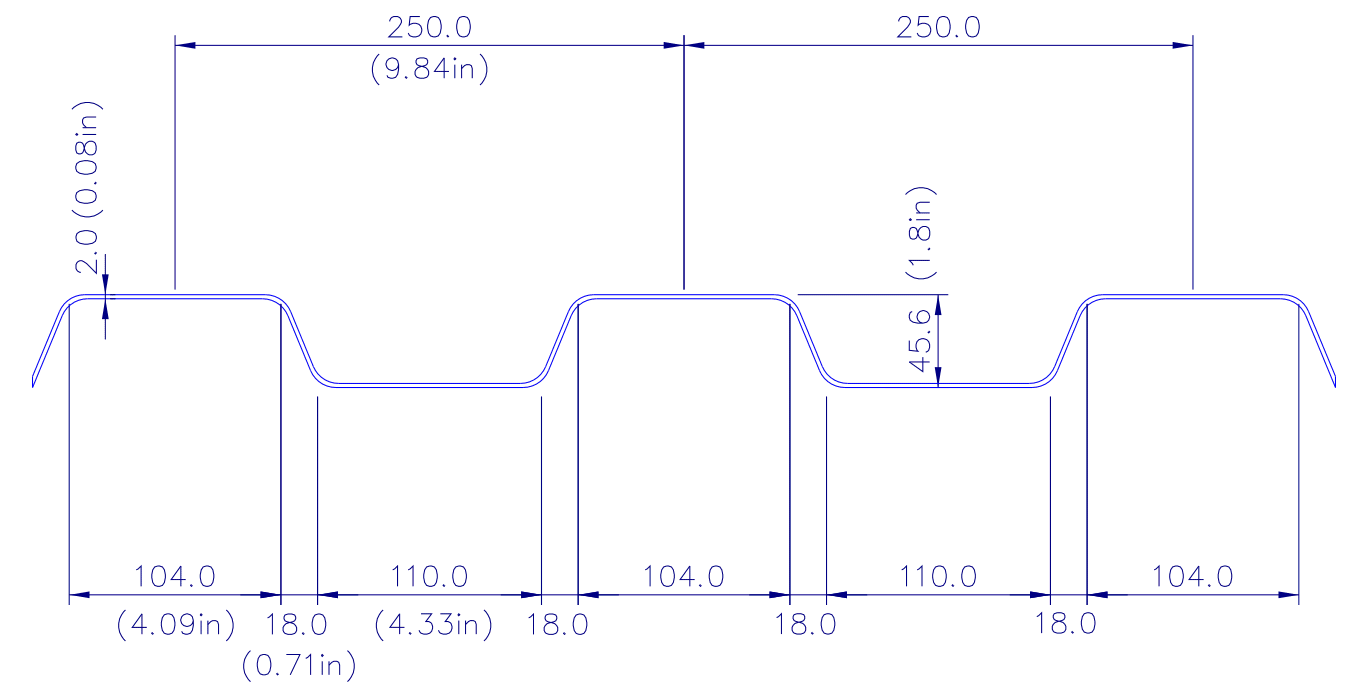

The roof of a shipping container has a unique shape that is a little different than the other pieces of sheet metal. Instead of just being a flat piece of steel that is bent in only one dimension (so that the entire length of the panel has the same cross-section as the back and sides), the roof is shaped in three dimensions.

- Shipping container end roll forming machine

Most containers only have one set of doors, while the other end is a solid wall of corrugated steel. This solid end has a different corrugation that is unique. However, it is oriented vertically, so it may appear similar to the side corrugation from far away.

- Shipping container door roll forming machine

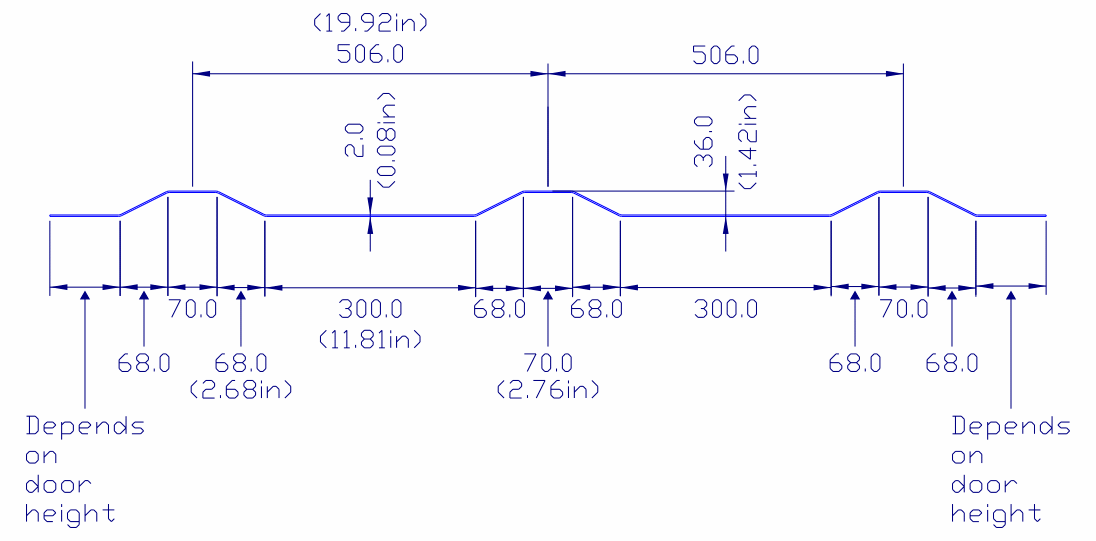

Every container has at least one set of doors, and the double-ended (tunnel) containers have two sets. The doors themselves have corrugations, though the number and orientation of the corrugations vary quite a bit between containers.

Typically there are two to five horizontal corrugations per door, although three is the most common and what we cover above. Usually, the horizontal corrugations are vertically centered on each door.

Linbay Machinery ia able to customize the roll forming machine to produce that profile according to what you provide.