3” Stainless Steel Trailer Tank Curved Omega Roll Forming Machine

Brief Introduction of 3MM Stainless Steel Trailer Tank Curved Omega Profile

These curved profiles are used as machine elements or pipes for different media in a variety of industries such as automotive, chemical, air traffic, construction and food and beverage.

Compared to other profiles, bending profiles represent the most unique part of it. Depending on the requirements for bending radius and dimensional accuracy, different machines and different methods are used. (Note: The production process described here is mainly for 3 mm stainless steel material.)

The specific configuration of each machine needs to be individually designed according to your profile and requirements. The bending section here we use an integral wall panel structure, the gearbox drive provides the power transmission and the curvature of the bending can be adjusted according to the required radius. In addition to OMEGA, other profiles such as T-, U- or C-profiles (channels) and stainless steel angles can also be bent to a specific radius.

In Mexico, there are many similar trailer tanks on the streets, which transport water, milk, petrol, etc. The bent OMEGA profile we have made is used for the repair and reinforcement of trailer tank bodies.

For this 3MM stainless steel trailer tank curved omega roll forming machine, we also have other related machines for reference.

1. 3MM Galvanized steel curved omega roll forming machine

2. Trailer tank fender roll forming machine

Machine details

This production line working speed is around 0-10m/min according to cutting length, the forming speed is around 0-12m/min adjustable.

Note: This machine configuration is based on 3mm(11 guage) stainless steel profile. The specific configuration should according to your profile.

Flow chart

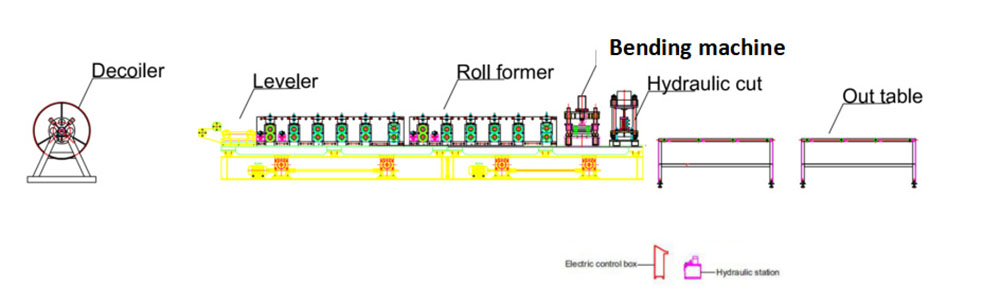

10 ton Hydraulic decoiler-Guiding-Leveler-Roll former-Bending machine-Hydraulic cut

Brief Introduction of 3MM Stainless Steel Curved Omega Roll Forming Machine

The curved omega roll forming machine has been designed for producing 3mm stainless steel omega profile for trailer tanks to reinforce.

Main components for this omega roll forming machine consists of a 10 ton hydraulic decoiler, guide, integrated leveler, main roll forming machine, bending machine, shearing, hydraulic stations, PLC control cabinet and out tables.

Due to the material and the thickness, the more specific configurations are 10 ton hydraulic decoiler, 125 Thickness Model iron cast structure, Z180 Thickness Model gear-box drive, 45kw motor power, Cr12Mov material rollers, φ100mm diameter roller shaft. Because of the 3MM stainless steel will require much more power to do the formation, iron cast can supply the strongest way to frame the whole line, and gear box can help offer the most stable pressure bearing function. What’s more, the big motor, great brilliant roller material and big diameter shaft, all of them is for the same pursuit, that is to enhance the whole production lines stability and intensity.

|

3MM Stainless Steel Curved Omega Roll Forming Machine |

|||

|

NO. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Cold-rolled steel, Galvanized steel, PPGI, stainless steel |

|

|

Thickness(mm):3mm |

|||

|

Yield strength: 250 - 550MPa |

|||

|

Tensile stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

0-12m/min |

Or according to your requirement |

|

3 |

Forming station |

18 |

According to your profile |

|

4 |

Bending station |

3 |

According to your profile |

|

5 |

Decoiler |

10 ton hydraulic decoiler |

According to your profile |

|

6 |

Main machine motor |

45kw Sino-German Brand |

Siemens |

|

7 |

PLC brand |

Panasonic brand |

Siemens/Delta |

|

8 |

Inverter brand |

Yaskawa brand |

Delta |

|

9 |

Driving system |

Gearbox drive Thickness Model Z180 |

Chain drive |

|

10 |

Rollers’ materail |

Cr12Mov |

Steel #45/GCr15 |

|

11 |

Station structure |

Forged Iron station Thickness Model 125 |

Wall panel structure |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

|

15 |

Contactor |

Schneider brand |

Or according to your requirement |

More details for the machine