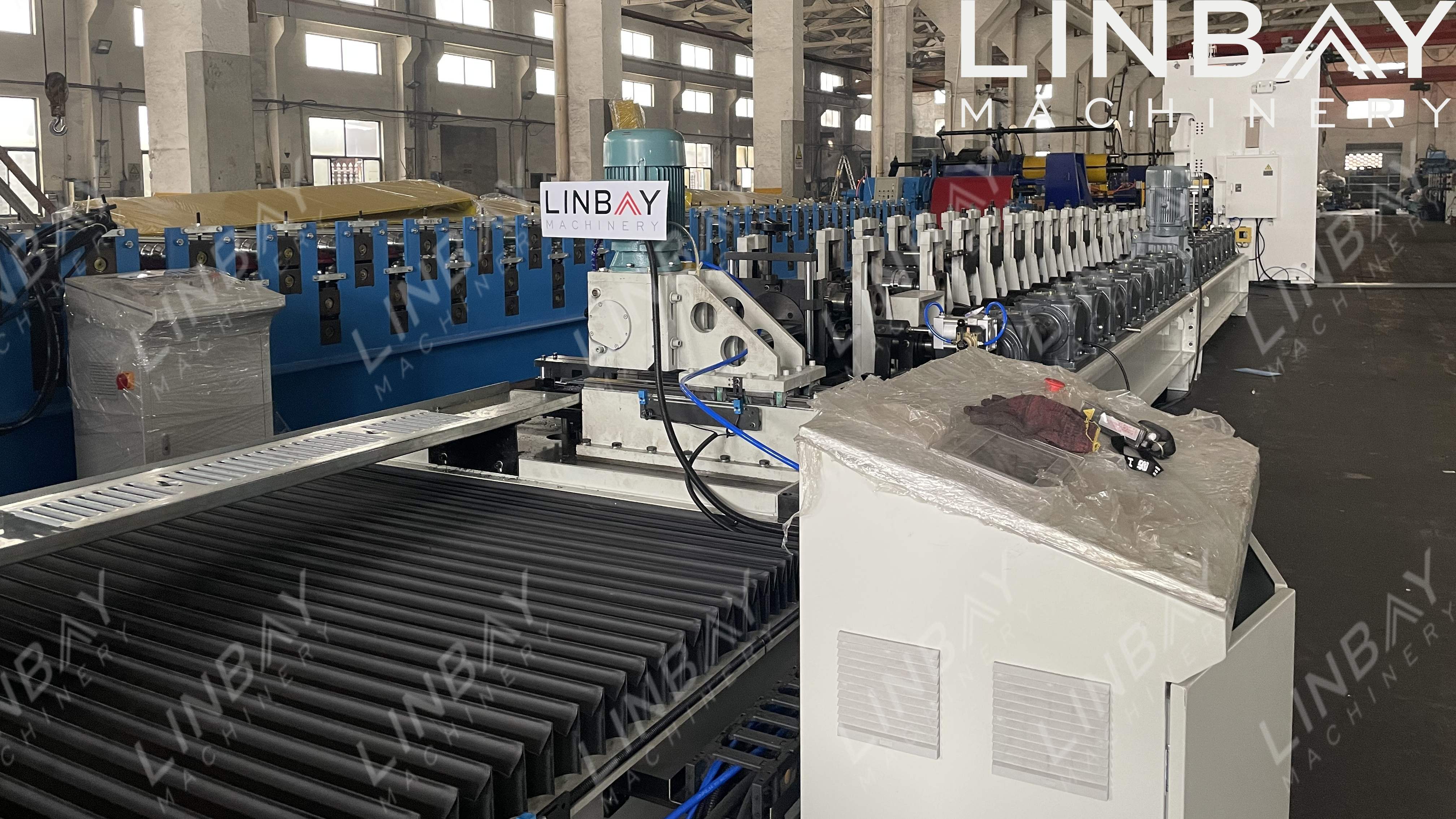

This roll former is used for the production of drainage gratings in two sizes. The profile thickness is 1.5 mm, and the material is galvanized steel. This type of profile has functions for drainage, anti-slip, load-bearing, and odor prevention, and is widely used in showers or floor drains. The speed can reach up to 12 m/min.

All our machines can be customized according to the customer’s drawings and budget. Additionally, before delivery, each machine undergoes multiple tests to ensure it meets production requirements and can operate stably over a long period.

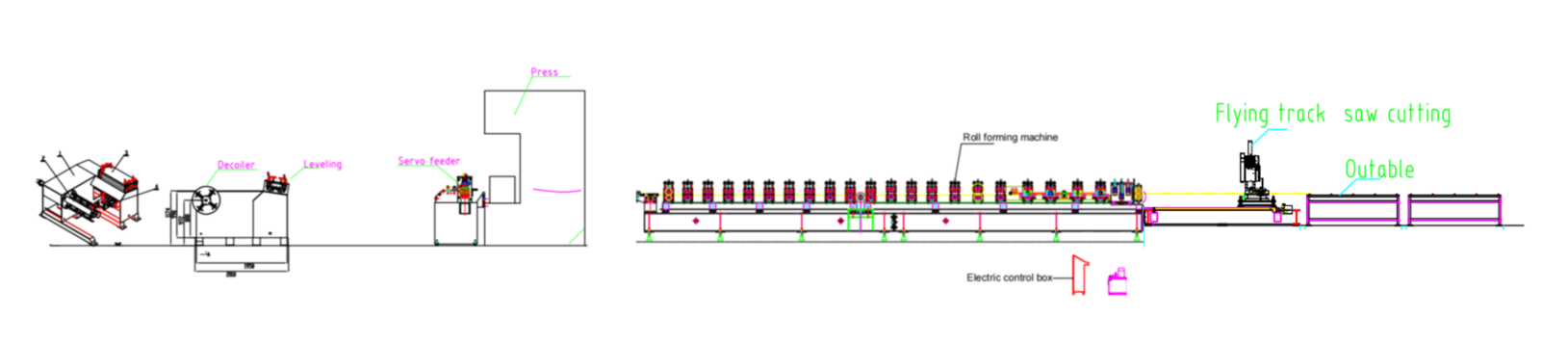

| Drainage grating roll forming machine | |||

| No. | Part | Specification | Optional |

| 1 | Raw material | Type: Galvanized steel | |

| Thickness(mm): 1.5mm | |||

| Yield strength: 250 - 550MPa | |||

| 2 | Speed (m/min) | 0-12m/min | Adjustable |

| 3 | Forming station | 18 | Dependes on the profile |

| 4 | Decoiler | Hydraulic decoiler and leveler | |

| 5 | Forming motor | Sino-German | Siemens |

| 6 | PLC | Panasonic | Siemens |

| 7 | Inverter | Yaskawa | |

| 8 | Transmission system | Gear box | |

| 9 | Roller material | GCr15 | |

| 10 | Structure | Cast iron support | |

| 11 | Method of changing profile sizes | Manual cassette change | |

| 12 | Punch Press | 160ton, 35-50 times/min | Hydraulic station |

| 13 | Number of mold | 2 | |

| 14 | Cut | Flying saw cut | |

| 15 | Energy | 380V 50Hz 3Ph | Or upon request |

| 16 | Color | White | Or upon request |

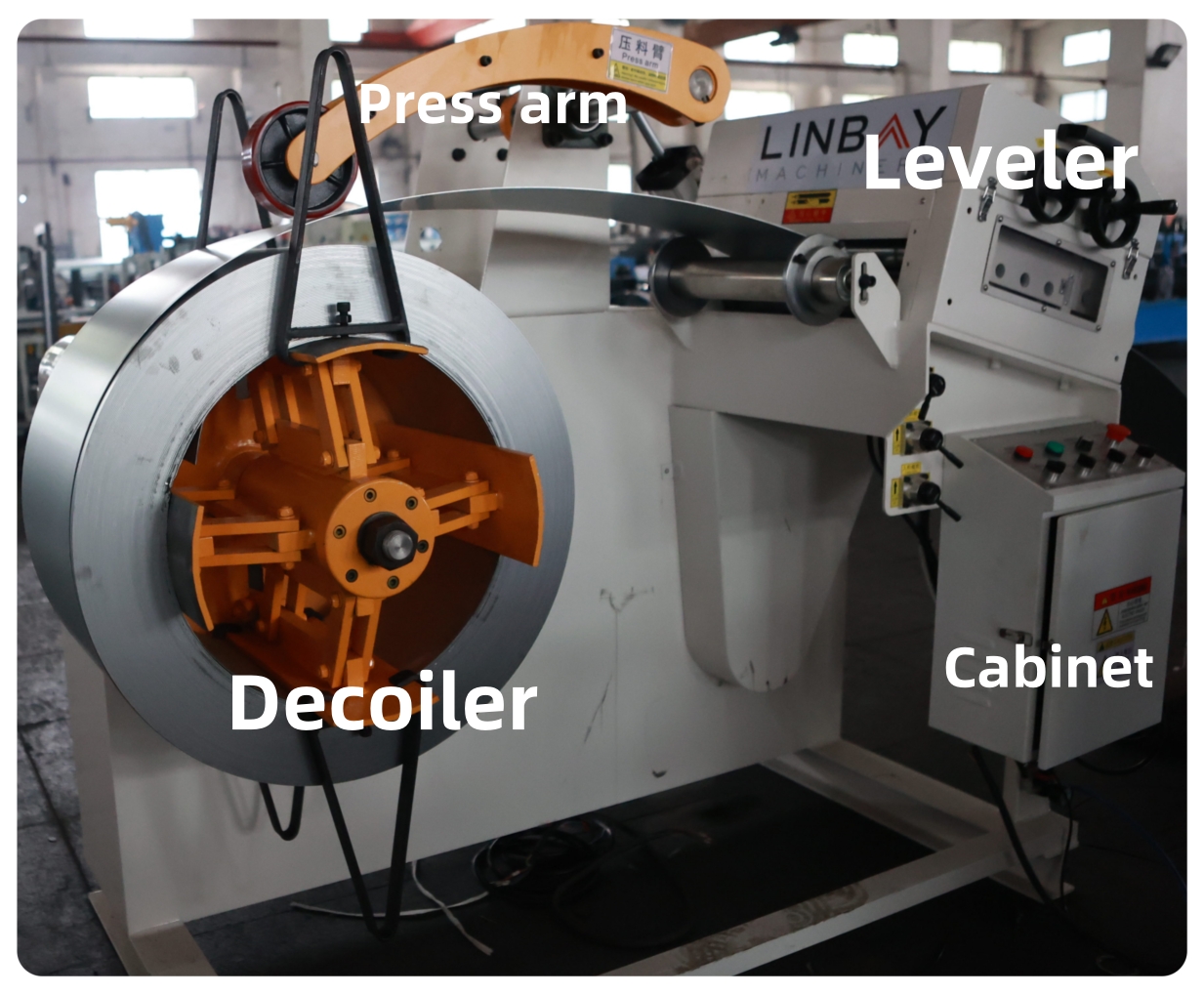

Decoiler: At the beginning of the production line, there is a combined decoiler and leveler. The decoiler has a pressure arm, which is used to prevent the steel coil from suddenly unwinding and causing injuries to workers. These hangers are also used to fix the position of the steel coil, providing safety for the workers.

Next to the decoiler is the leveler. There are a total of 7 leveling rollers and 4 pressure rollers. After leveling, the steel coil will release internal stresses and become more even, preparing it for the subsequent punching process.

This combined decoiler and leveler, compared to separate decoiler and leveler units, shortens the distance between the production lines and saves space. This is because separate decoiler and leveler units require a distance of 3 to 4 meters between them.

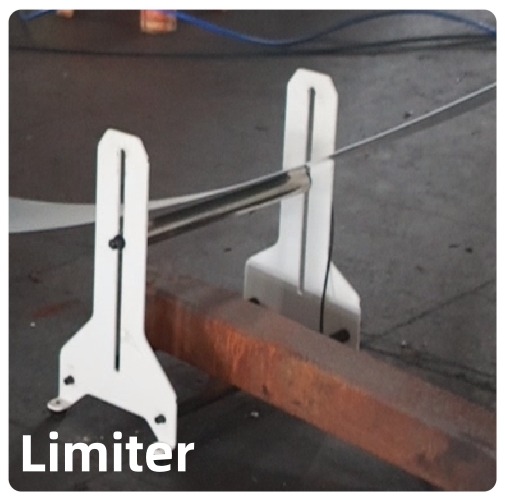

Limiter: Between the decoiler and the punch press, there is a limit sensor. It is connected to the punching machine and is used to detect the steel strip.

Punch Press: In the punching section, we use a 160-ton punch press, with a speed of 35-50 strokes per minute. The punch press operates faster than the hydraulic station, which can increase the efficiency of the entire production line. Each size requires a set of molds, so a total of 2 sets of molds are needed. When changing the production size, the corresponding molds in the press also need to be replaced. Additionally, the punch press is equipped with a servo motor feeder, which ensures precise punching position and fast feeding. There is a separate electrical cabinet to control the punch press. We will provide a manual to facilitate the customer's operation.

Limiter: Between the punch press and the roll former, there is a frame with limit sensors. The frame contains two sensors. The upper sensor is connected to the roll former, and when the steel strip touches this sensor, it indicates that the roll former is operating too quickly and should stop. The lower sensor is connected to the punch press, and when the steel strip touches this sensor, it indicates that the punch press is operating at an excessive speed and should stop. This device is used to adjust the speed of the different parts of the production line and protect the machinery.

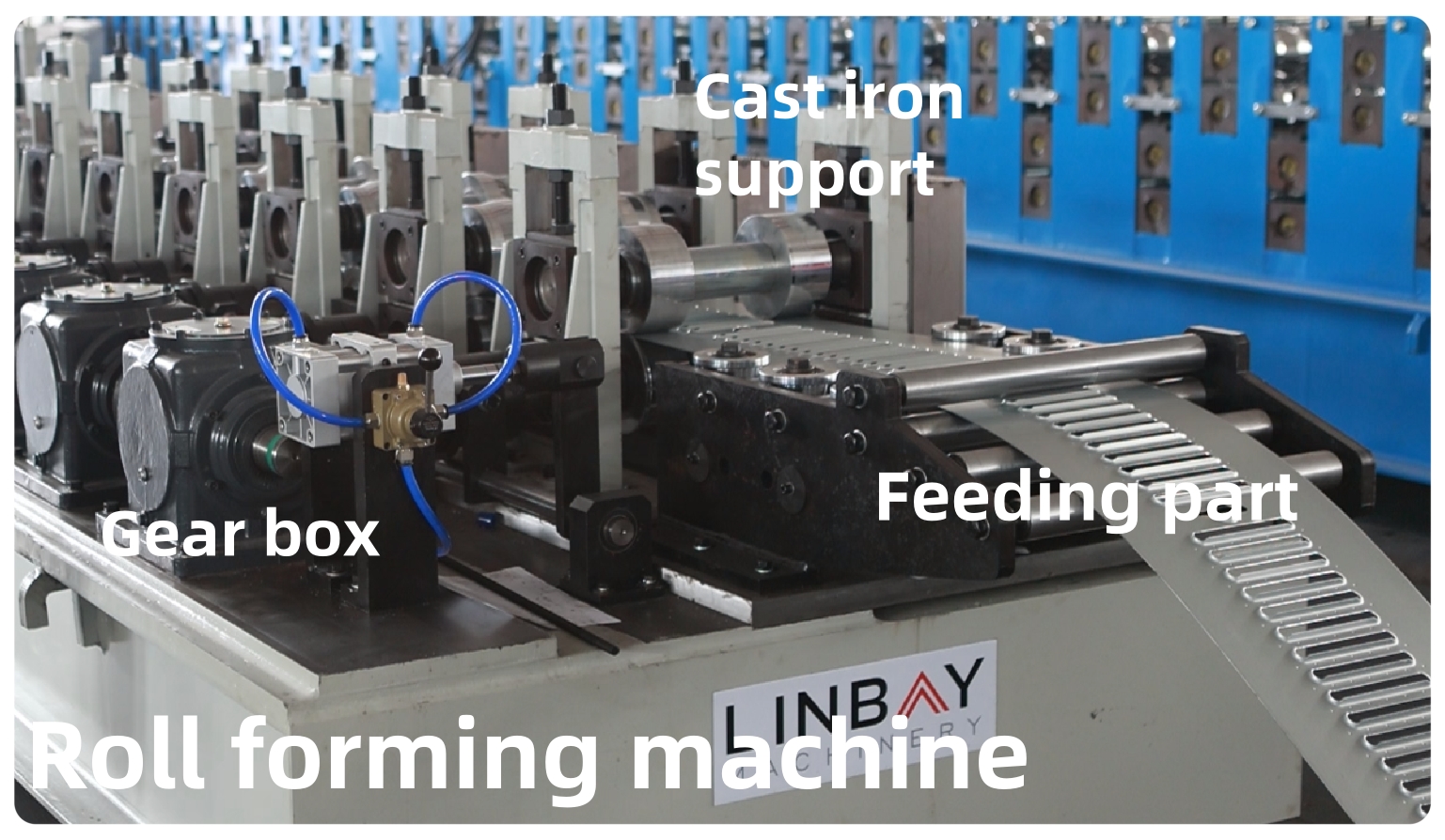

Roll forming machine: The roll former has a structure of cast iron supports with power transmission through gearboxes. This is a very stable and durable structure. Since two sizes need to be produced, there is a total of 2 sets of rollers (2 cassettes). When changing the production size, the corresponding cassette needs to be replaced; this operation can take from half an hour to an hour, but it will become faster with experience. The rollers used have also been treated with chrome to increase their corrosion resistance and extend lifespan.

Flying saw cut: In this case, we use flying saw cut. In the cutting section, coolant is sprayed to cool the saw blade and prevent chip dispersion. Flying cutting means that the roll former continues working while the profile is being cut, which can increase production speed. We use a servo motor to control the tracking movement of the cutting part. Before cutting, we use a straightener to ensure the profile’s straightness. The cut profile is also burr-free.

Spare parts box / Installation video / Manual: We offer our customers a set of spare parts that includes various essential components, allowing for quick replacement in case any part of the machine gets damaged. To ensure the production line is correctly set up upon receiving the equipment, we include an installation video that guides through each step of the process. Additionally, we provide a detailed instruction manual, available in English and other languages as needed, offering all the essential information for operators to handle the machine efficiently.

We have a factory in China and, at the same time, an office and showroom in Mexico. We have engineers who speak both English and Spanish to offer after-sales service to our customers, addressing the issue of inadequate support after purchasing machines from China.